Preparation method of hydrogen storage alloy material

A hydrogen storage alloy and raw material solution technology, applied in the field of alloy materials, can solve the problems of uneven composition, high production cost, and many alloy defects, and achieve the effect of simple synthesis method, no segregation, and uniform alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

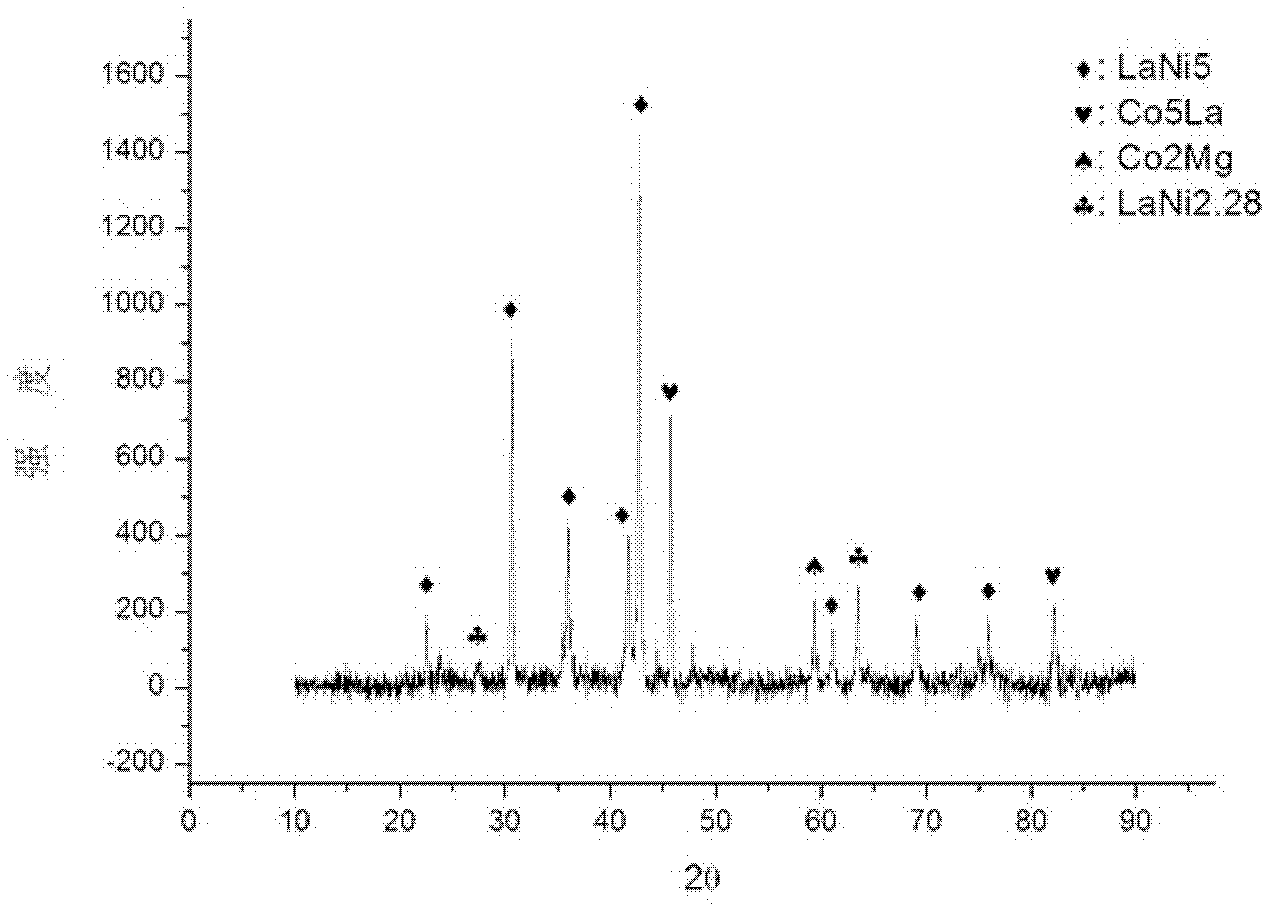

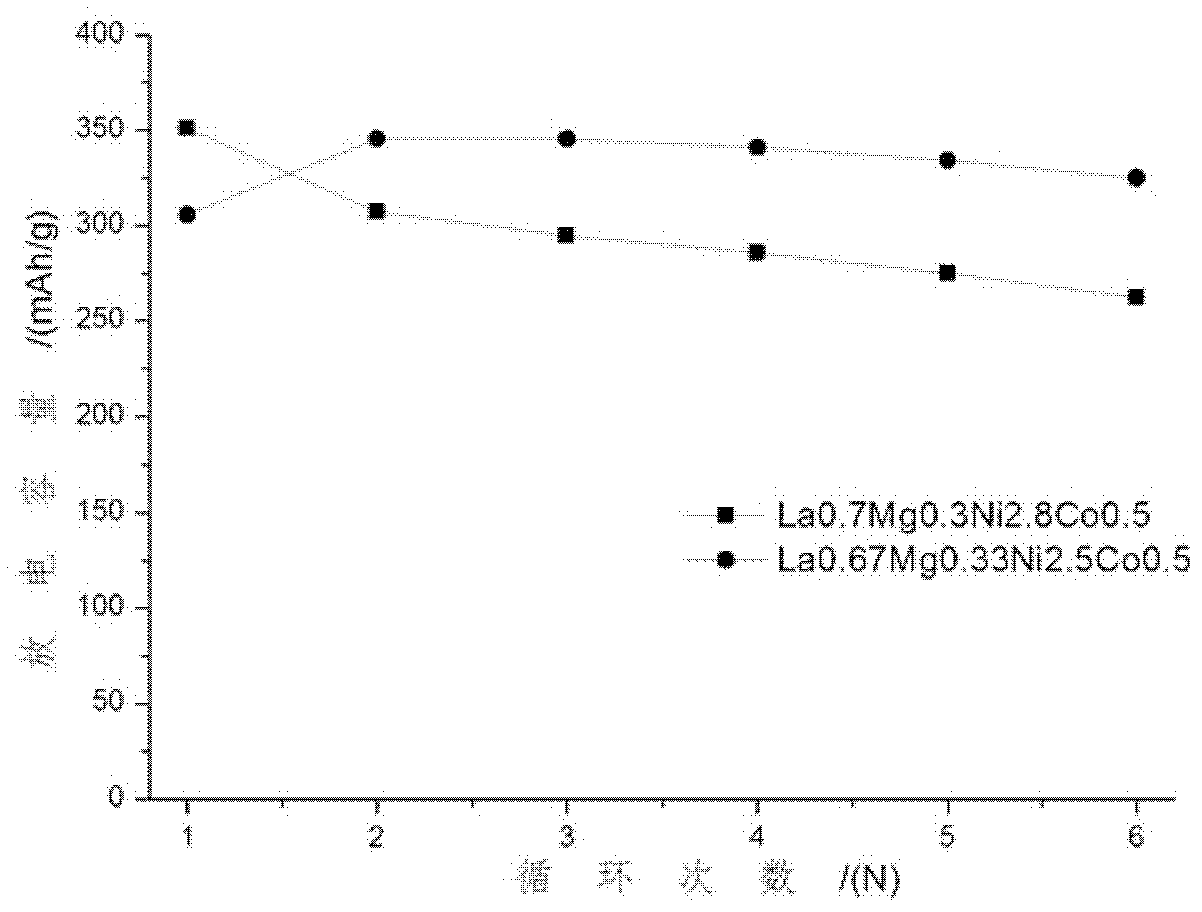

[0025] First, the La 2 o 3 The powder is burned to remove water and adsorbates, and dissolved in nitric acid with a volume ratio of 1:1 (the ratio of distilled water follows) to prepare La(NO 3 ) 3Solution, dissolving magnesium salt, nickel salt and cobalt salt in distilled water to prepare a solution containing Mg, Ni and Co. Taking the prepared product 8g as the standard, according to the product La 0.67 Mg 0.33 Ni 2.5 co 0.5 The atomic ratio of each metal salt solution is accurately pipetted in a beaker, wherein the La element is over 25%. At this time, the total content of each metal ion in the metal salt mixed solution is 37g / L, which is placed in a constant temperature water bath, and quickly Stir, and after the temperature is constant, quickly drop 250 mL of 0.5 mol / L oxalic acid-ethanol solution (the amount added is 150% of the theoretical amount) with an acid burette. After the precipitation is complete, age the solution, then wash the precipitate, filter, dry....

Embodiment 2

[0029] With the same raw material solution among the embodiment 1, take preparation product 8g as standard, press product La 0.7 Mg 0.3 Ni 2.8 co 0.5 The atomic ratio of each metal salt solution is accurately pipetted in a beaker, wherein the La element is excessive by 25%. At this time, the total content of each metal ion in the metal salt mixed solution is 37.6g / L, which is placed in a constant temperature water bath. Stir rapidly, and after the temperature is constant, quickly add 248 mL of 0.6 mol / L oxalic acid-ethanol solution (the amount added is 150% of the theoretical amount) dropwise with an acid burette. After the precipitation is complete, age the solution, and then wash the precipitate for 3- 6 times, filter, dry, burn to get La 0.7 Mg 0.3 Ni 2.8 co 0.5 Alloy oxide precursor, and then the oxide and CaH 2 mixed, CaH 2 The amount is 2 times of the theoretical value, placed in a vacuum / atmosphere tube electric furnace for reduction, and the resulting reduced p...

Embodiment 3

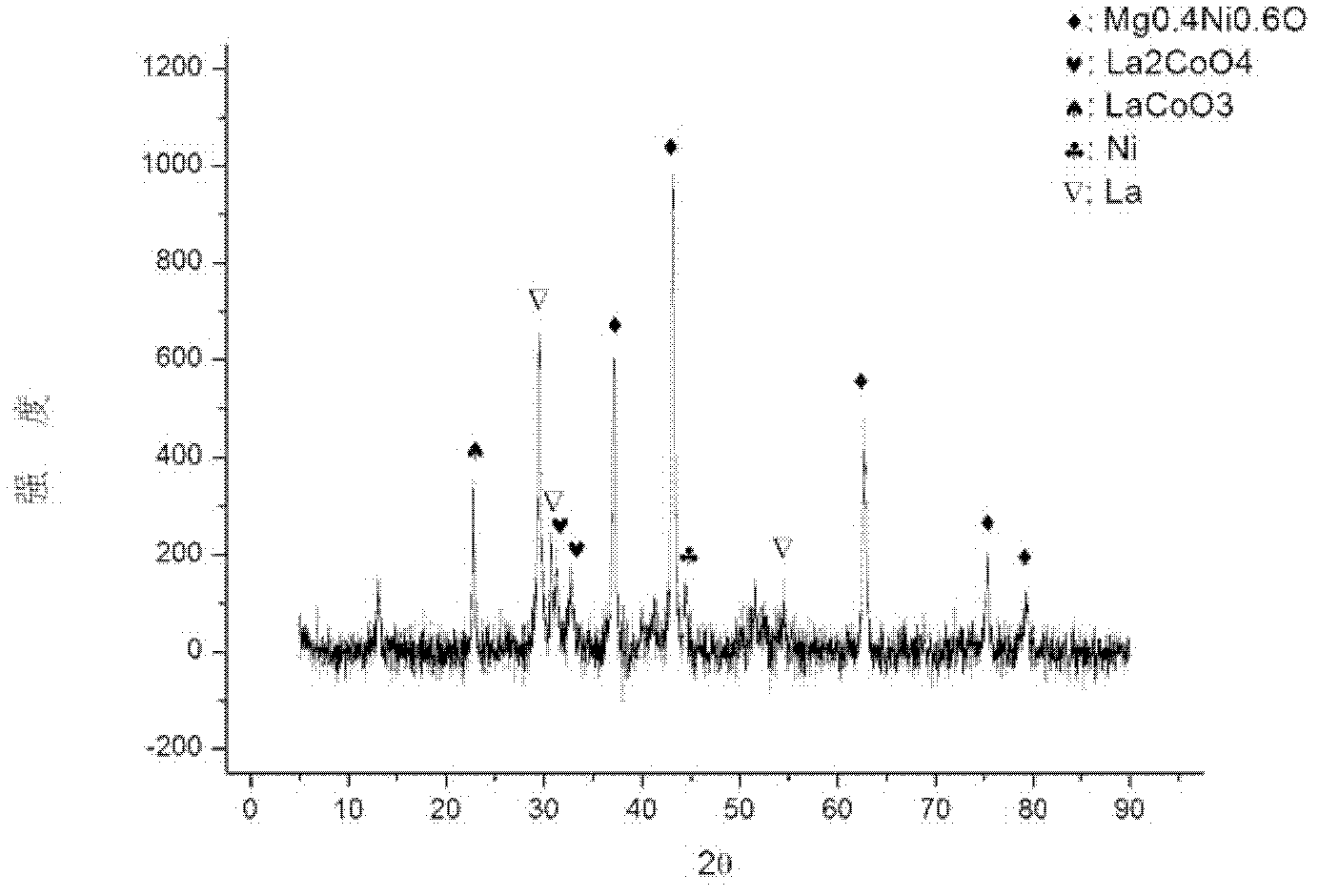

[0031] With the same raw material solution among the embodiment 1, take preparation product 8g as standard, press product La 0.75 Mg 0.25 Ni 3.2 co 0.3 The atomic ratio of each metal salt solution is accurately pipetted in a beaker, wherein the La element is excessive by 25%. At this time, the total content of each metal ion in the metal salt mixed solution is 40g / L, which is placed in a constant temperature water bath, Stir quickly, and after the temperature is constant, quickly add 247mL of 0.7mol / L oxalic acid-ethanol solution dropwise with an acid burette (the amount added is 150% of the theoretical amount), after the precipitation is complete, age the solution, and then wash the precipitate for 3~ 6 times, filter, dry, burn to get La 0.75 Mg 0.25 Ni 3.2 co 0.3 Alloy oxide precursors. The atomic ratio of each metal element is consistent with the set composition through X-ray fluorescence probe detection, and the X-ray results show that it is in a good crystal state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com