Determination method for lactoferrin content in dairy products

A method for measuring lactoferrin, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as large errors, poor quantitative repeatability, and instrument damage, and achieve the effects of reducing testing costs, improving accuracy, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The content determination of lactoferrin in embodiment 1 fresh milk

[0047] (1) Accurately weigh 10g of fresh milk sample, dissolve it completely in 30mL of water, make it up to 50ml, and then centrifuge at 4°C for 10min at a centrifugal speed of 8000r / min to remove fat to obtain a skim emulsion;

[0048] (2) Over-affinity chromatography column: the affinity chromatography column is preactivated by using a sodium phosphate buffer solution with a pH of 6.8, and 10 ml of skim emulsion is passed through the affinity chromatography column, and the pH of 5 mL is 6.8 sodium phosphate Wash the column with buffer, then elute with 5mL of eluent ①, collect the eluate, and filter it with a 0.45μm pore size aqueous phase filter membrane to obtain the sample solution; wherein, the eluent ① contains 1.0mol / L sodium chloride in sodium phosphate buffer, pH 6.8;

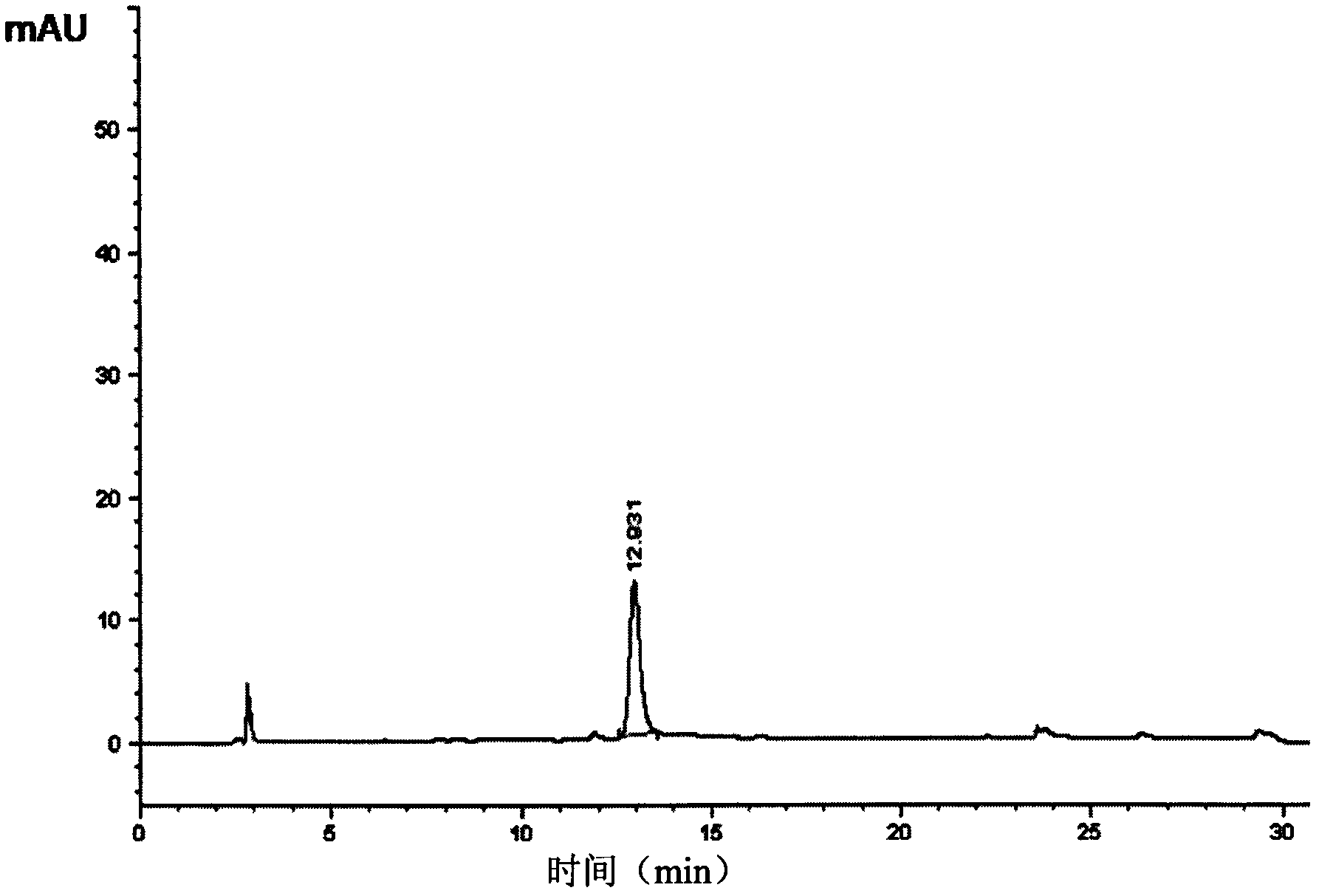

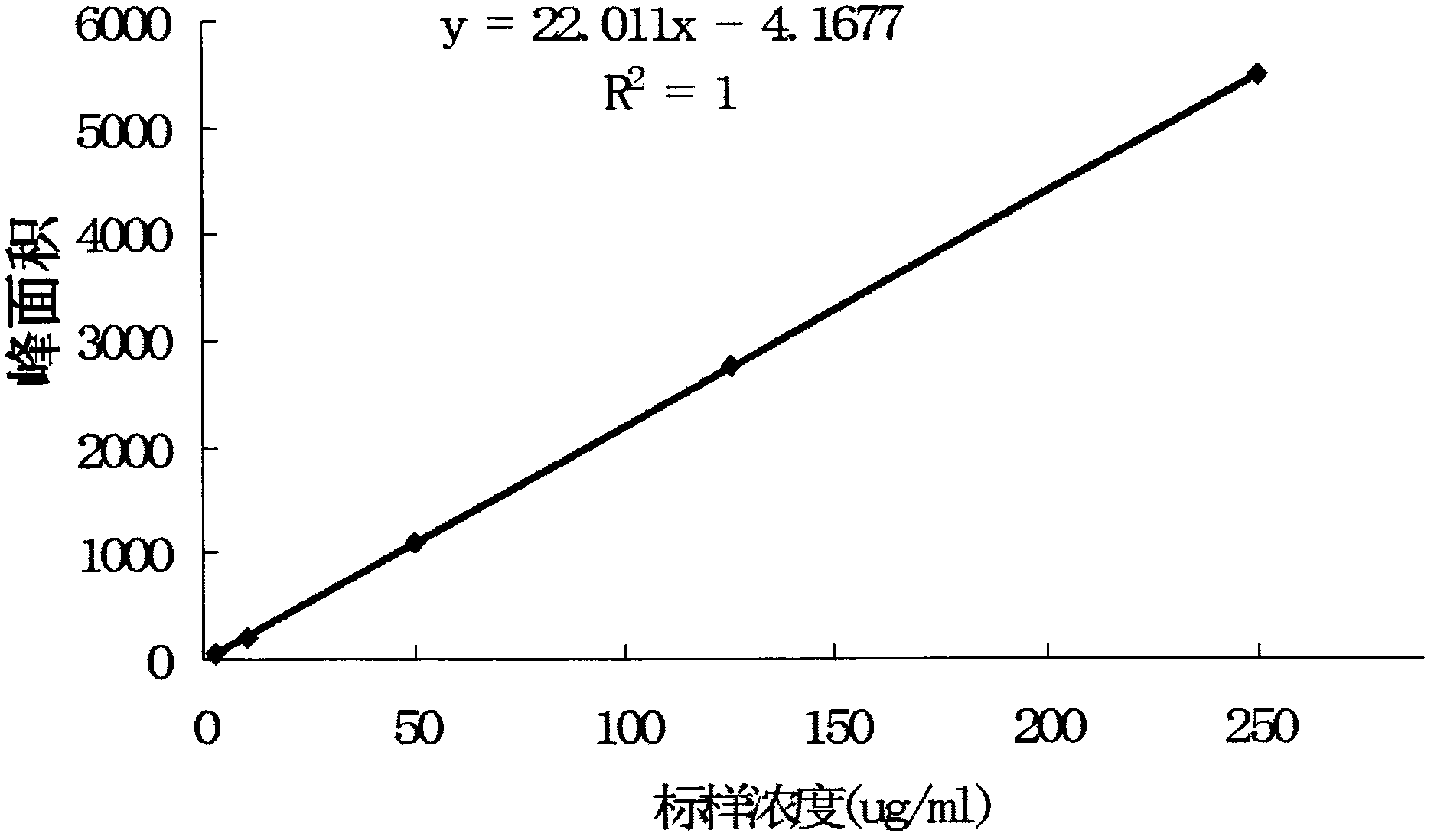

[0049] (3) Take 20 μL of the sample solution and put it into the high performance liquid chromatograph for gradient elutio...

Embodiment 2

[0057] The content determination of lactoferrin in embodiment 2 baby milk powder

[0058] (1) Accurately weigh 5g of infant milk powder sample, dissolve it completely in 40mL of 30°C water, set the volume to 50ml, and then centrifuge at 0°C for 20min at a centrifugal speed of 5000r / min to remove fat to obtain a skim emulsion;

[0059] (2) Over-affinity chromatography column: the affinity chromatography column is preactivated by using a sodium phosphate buffer solution with a pH of 7.4, and 10 ml of skim emulsion is passed through the affinity chromatography column, and the pH of 5 mL is 7.4 sodium phosphate Wash the column with buffer, then elute with 5mL of eluent ①, collect the eluate, and filter it with a 0.45μm pore size aqueous phase filter membrane to obtain the sample solution; wherein, the eluent ① contains 1.0mol / L sodium chloride in sodium phosphate buffer, pH 7.4;

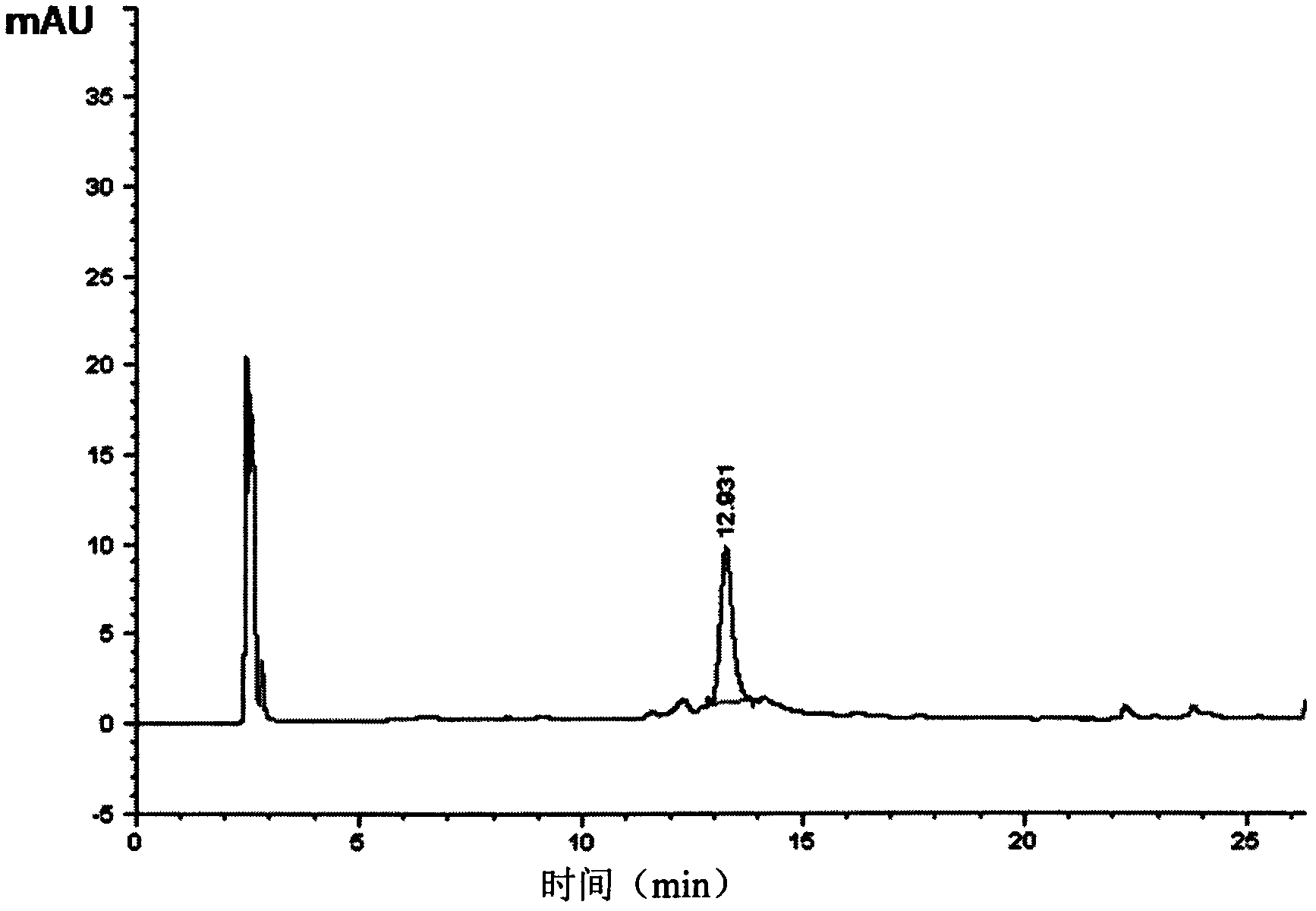

[0060] (3) Take 20 μL of the sample solution and put it into the high performance liquid chromatogra...

Embodiment 3

[0068] The content determination of lactoferrin in embodiment 3 bigger infant milk powder

[0069] (1) Accurately weigh 5g of a larger infant milk powder sample, dissolve it completely in 40mL of 30°C water, set the volume to 50ml, and then centrifuge at 4°C for 15min at a centrifugal speed of 6000r / min to remove fat to obtain a skim emulsion;

[0070] (2) Over-affinity chromatography column: the affinity chromatography column is preactivated by using a sodium phosphate buffer solution with a pH of 7.0, and 10 ml of skim emulsion is passed through the affinity chromatography column, and the pH is 7.0 with 5 mL of sodium phosphate Wash the column with buffer, then elute with 5mL of eluent ①, collect the eluate, and filter it with a 0.45μm pore size aqueous phase filter membrane to obtain the sample solution; wherein, the eluent ① contains 1.0mol / L sodium chloride in sodium phosphate buffer, pH 7.0;

[0071] (3) Take 20 μL of the sample solution and put it into the high-perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com