Method for manufacturing X-ray diffraction grating with large height-width ratio

A diffraction grating and X-ray technology, which is applied in the field of manufacturing X-ray diffraction gratings with large aspect ratios, can solve problems such as sticking and photoresist collapse, and achieve a simple manufacturing process, avoiding inaccurate alignment problems, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

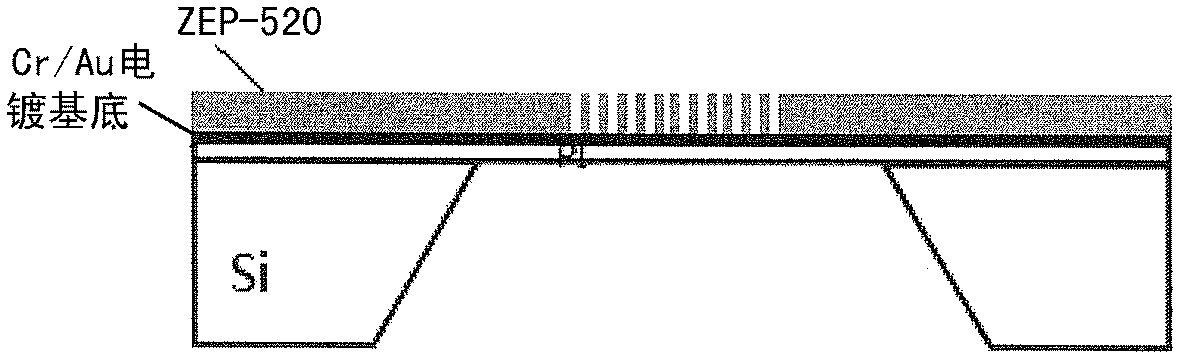

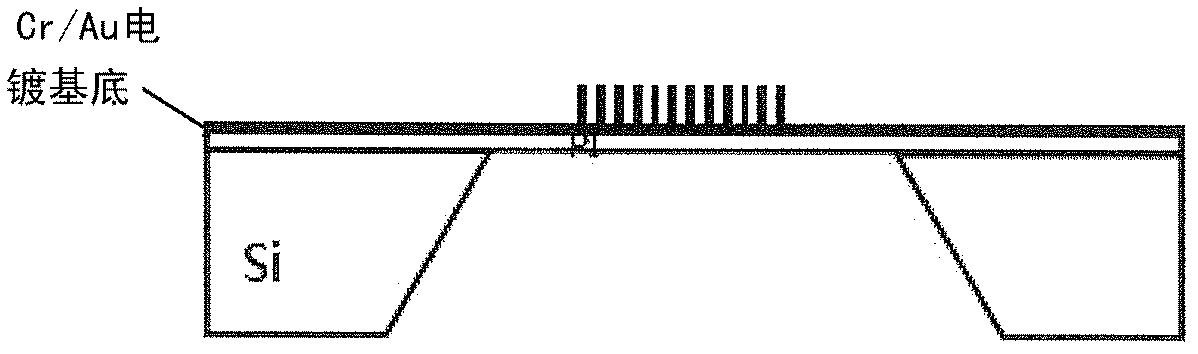

[0029] The method for making X-ray diffraction grating with large aspect ratio provided by the present invention does not form a photoresist with a large aspect ratio, divides the photoresist into two layers to reduce the thickness, and evaporates a thin gold layer in the middle to form a support, thereby realizing Components with high line width requirements, specifically include the following steps:

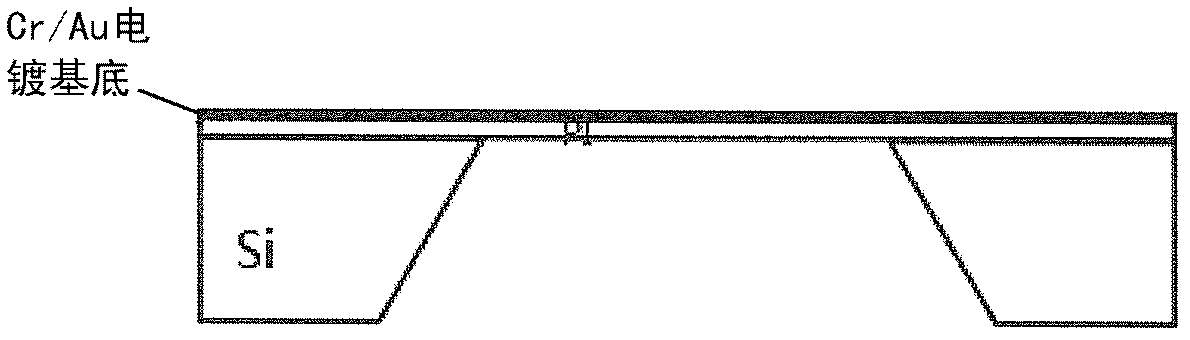

[0030] Step 1: Spin-coat a layer of 1 μm polyimide PI on the front of a clean silicon substrate, and wet-etch the silicon substrate from the back of the silicon substrate until the polyimide PI is formed to form a hollow polyimide. Imide PI film, and then evaporate a layer of 5nmCr / 10nmAu on the polyimide PI film as an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com