LED (Light Emitting Diode) surface patterning method

A surface pattern and surface material technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing light extraction efficiency and achieve the effect of simple preparation principle, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

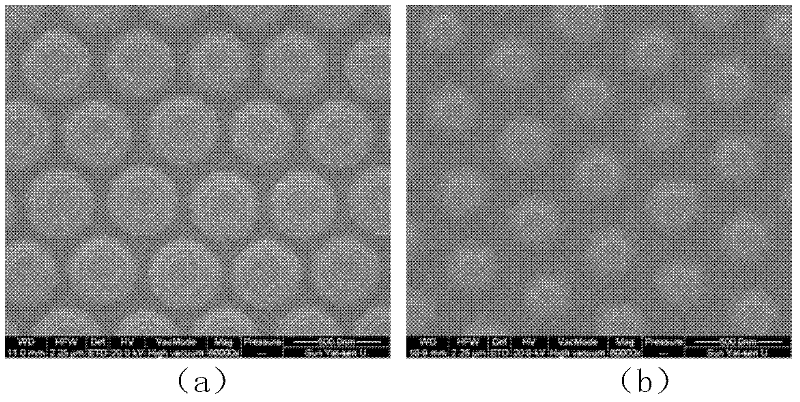

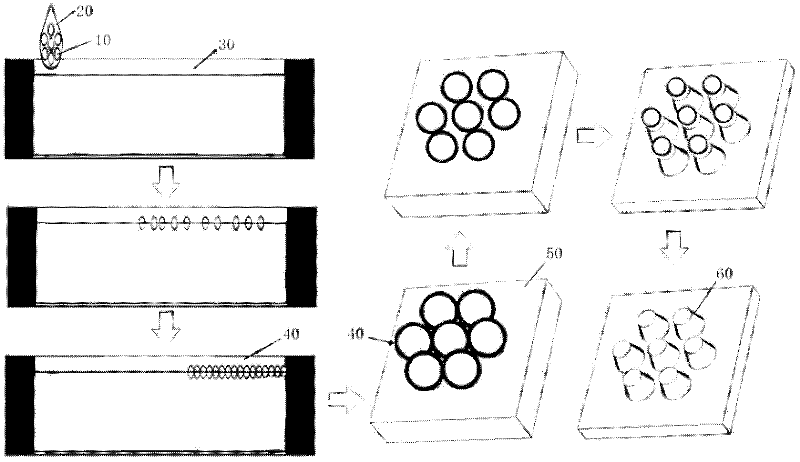

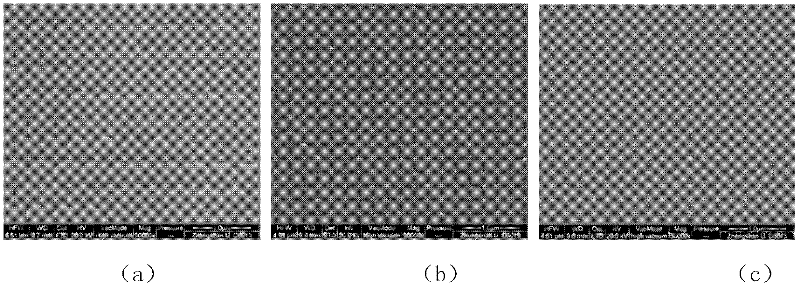

[0047] Take the polystyrene microsphere solution with a diameter of 450nm and mix it with alcohol in equal proportions, and then transfer the polystyrene microspheres to the surface of deionized water with a small-bore syringe and slide buffer to spread evenly. Dropping sodium lauryl sulfate active agent changes the surface tension of water, making the microspheres aggregate and self-assemble into a hexagonal close-packed array to form a polystyrene monolayer microsphere film, such as figure 2 (a) shown. Transfer the single-layer microsphere film to the surface of the LED, and heat the LED at 70°C for 20 minutes, so that each microsphere in the single-layer microsphere film adheres to the surface of the LED to avoid drifting and damage of the microspheres. lattice array. Then clean the sample with oxygen ions, the experimental power is 35W, the oxygen flow rate is 600sccm, and the cleaning time is about 180s.

[0048] Then etch the single-layer microsphere film 9s and 15s i...

Embodiment 2

[0050] Take the polystyrene microsphere solution with a diameter of 308nm and mix it with alcohol in equal proportions, then transfer the polystyrene microspheres to the surface of deionized water and spread them evenly using a small-bore syringe and slide buffer. Dropping sodium lauryl sulfate active agent changes the surface tension of water, making the microspheres aggregate and self-assemble into a hexagonal close-packed array to form a polystyrene monolayer microsphere film, such as figure 2 (b) shown. Transfer the single-layer microsphere film to the surface of the LED, and heat the LED at 70°C for 20 minutes, so that each microsphere in the single-layer microsphere film adheres to the surface of the LED to avoid drifting and damage of the microspheres. lattice array. Then clean the sample with oxygen ions, the experimental power is 35W, the oxygen flow rate is 600sccm, and the cleaning time is about 180s.

[0051] Then etch the single-layer microsphere film 11s in th...

Embodiment 3

[0053] Take the polystyrene microsphere solution with a diameter of 187nm and mix it with alcohol in equal proportions, then transfer the polystyrene microspheres to the surface of deionized water with a small-bore syringe and slide buffer to spread evenly. Dropping sodium lauryl sulfate active agent changes the surface tension of water, making the microspheres aggregate and self-assemble into a hexagonal close-packed array to form a polystyrene monolayer microsphere film, such as figure 2 (c) shown. Transfer the single-layer microsphere film to the surface of the LED, and heat the LED at 70°C for 20 minutes, so that each microsphere in the single-layer microsphere film adheres to the surface of the LED to avoid drifting and damage of the microspheres. lattice array. Then clean the sample with oxygen ions, the experimental power is 35W, the oxygen flow rate is 600sccm, and the cleaning time is about 60s.

[0054] Then etch the single-layer microsphere film in the vertical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com