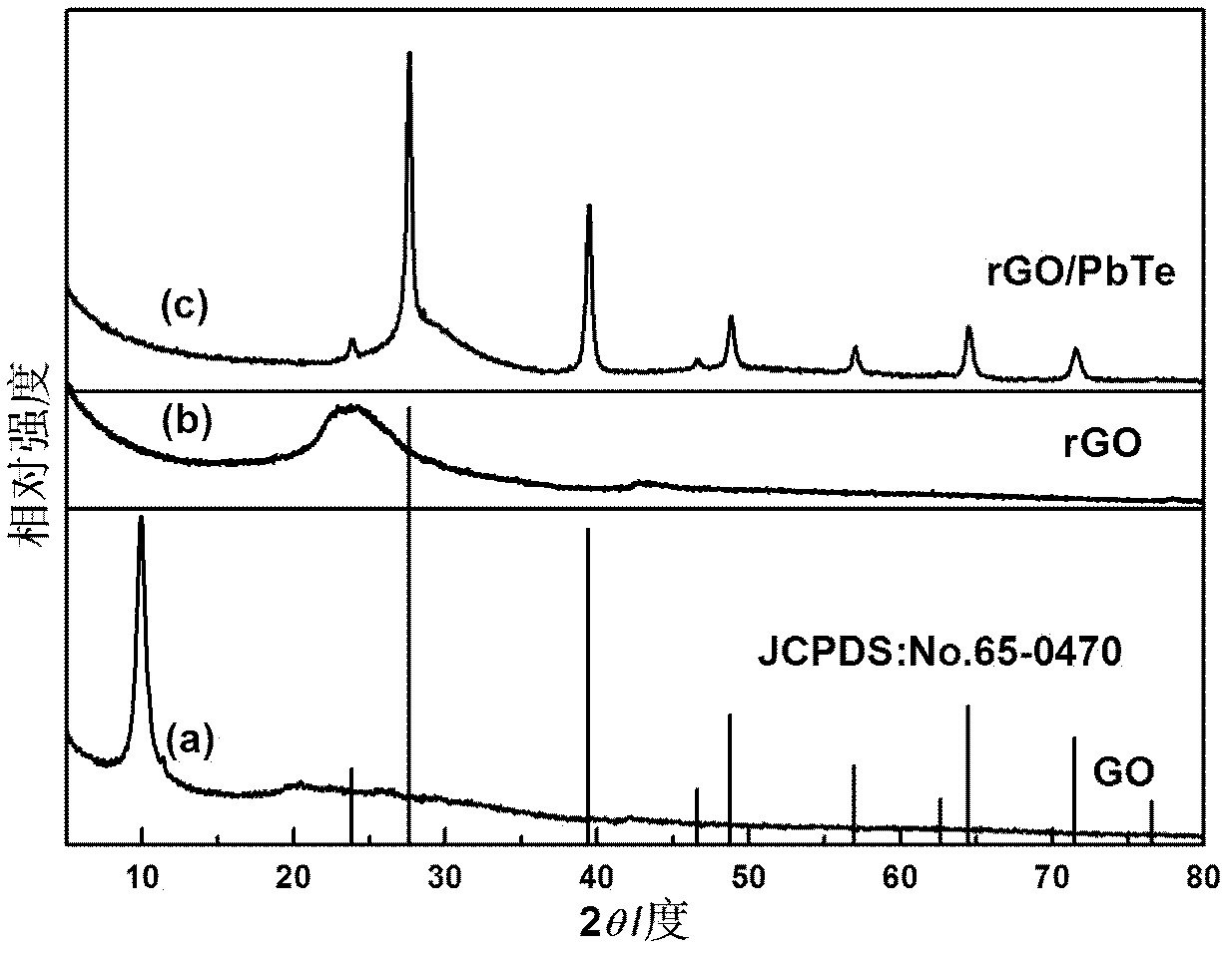

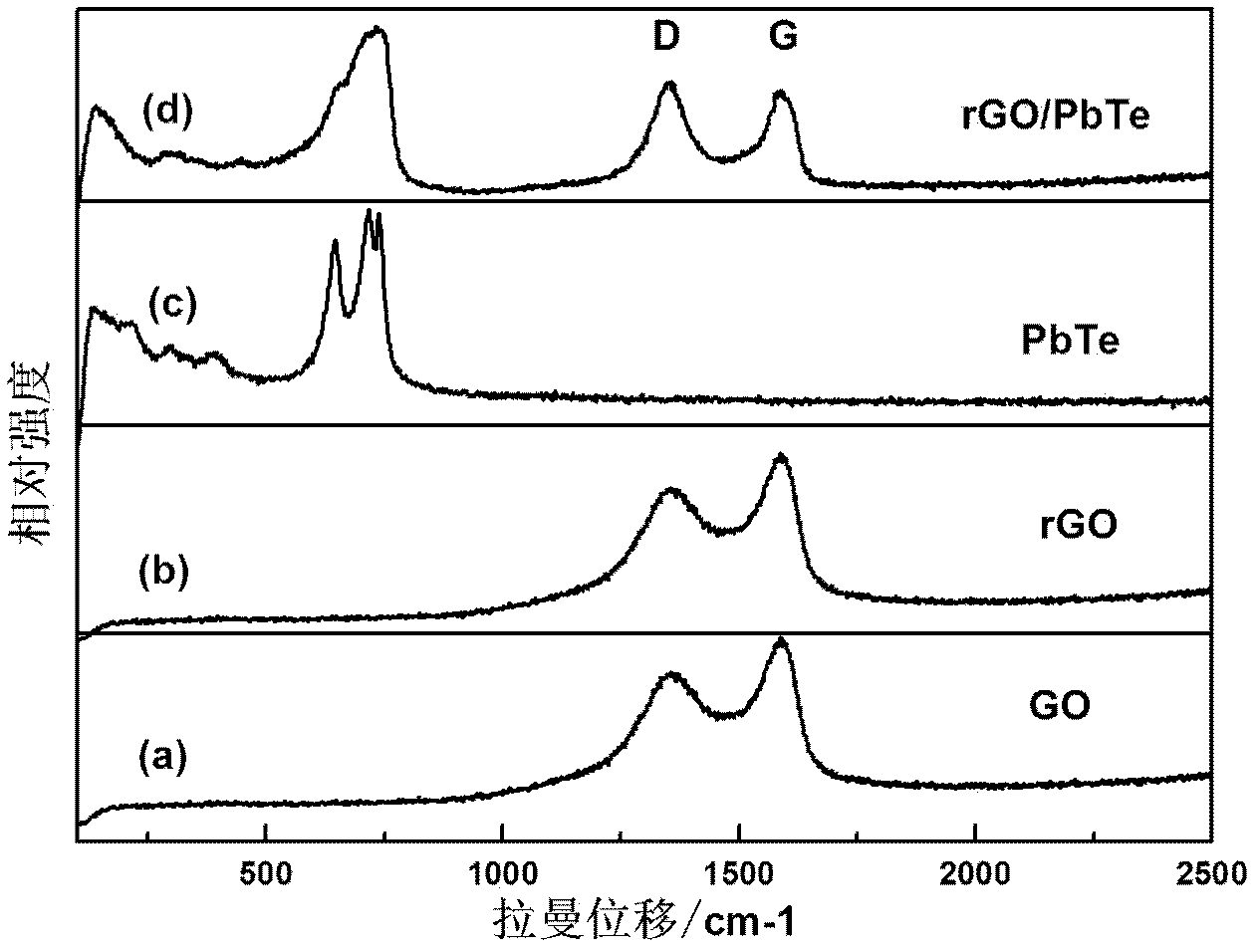

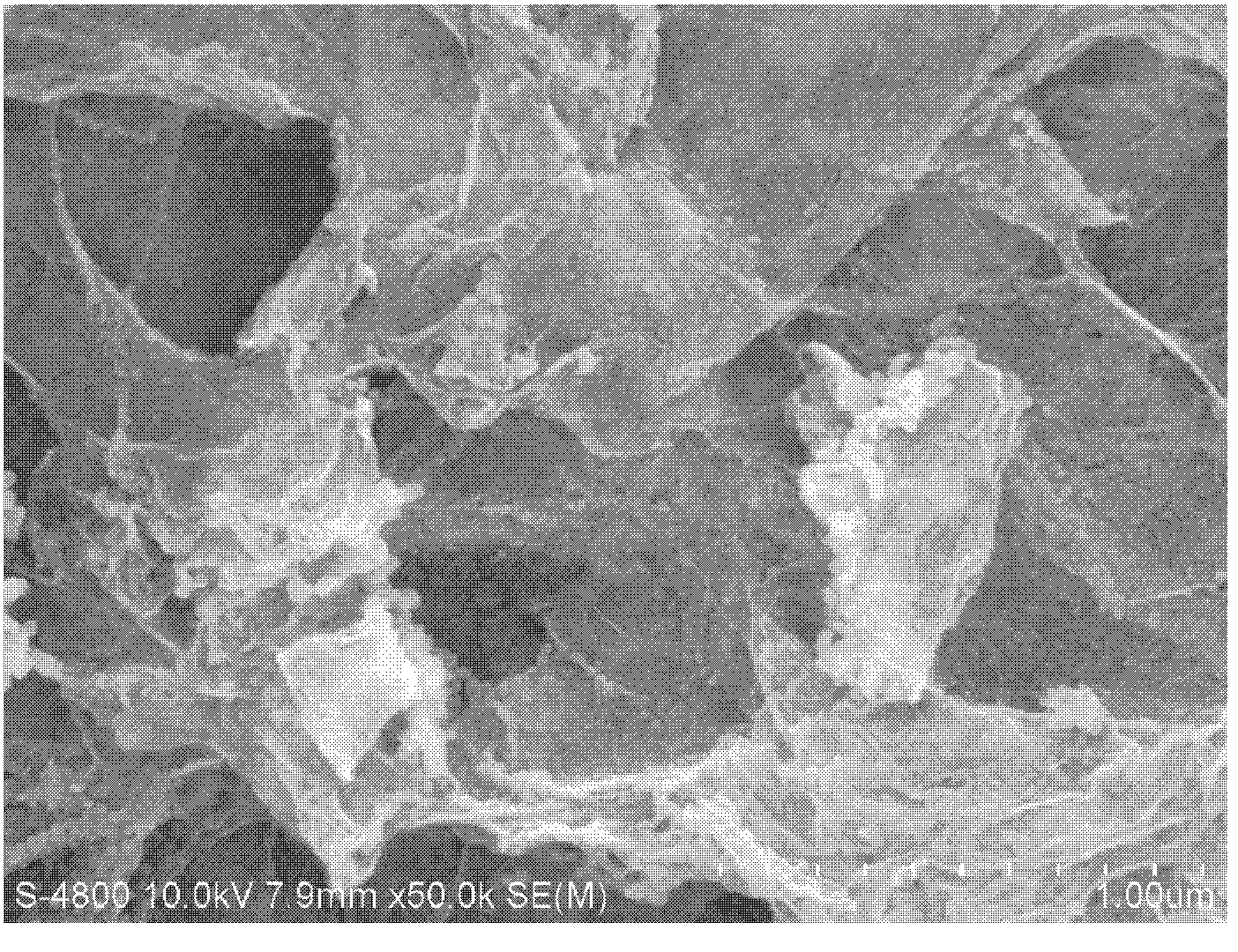

Plumbum telluride (PbTe) or graphene nanocomposite material and preparing method thereof

A nanocomposite material, graphene technology, applied in the field of PbTe/graphene nanocomposite material and its preparation, can solve problems such as gaps, and achieve the effects of low energy consumption, wide application prospect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of graphite oxide (GO):

[0049] 1) In the low temperature reaction stage, add 116ml of 98wt% concentrated sulfuric acid to a dry reaction vessel and cool it down to 0°C, add 5g of graphite powder and NaNO during stirring 3 2.5g, after mixing evenly, slowly add 15g of potassium permanganate, control the reaction temperature at 0-8°C, and stir for 1.5h;

[0050] 2) In the medium temperature reaction stage, place the above reaction vessel in a constant temperature water bath at 36°C and stir evenly for 30 minutes;

[0051] 3) In the high-temperature reaction stage, slowly add 250ml of warm water at 50-60°C and 30ml of hydrogen peroxide with a mass concentration of 30wt% into the container after the end of the medium temperature, and finish the reaction after stirring for 15 minutes. 4 2- (with BaCl 2 solution detection), and then freeze-dried to obtain graphite oxide.

[0052] (2) Preparation of composite materials:

[0053] 1) with Pb(CH 3 COO) 2 ...

Embodiment 2

[0061] (1) Preparation of graphite oxide (GO):

[0062] 1) In the low-temperature reaction stage, add 120ml of 98wt% concentrated sulfuric acid to a dry reaction vessel, cool to 4°C, add 5g of graphite powder and NaNO while stirring 3 1.5g, after mixing evenly, slowly add 17g of potassium permanganate, control the reaction temperature at 0-7°C, and stir for 2h;

[0063] 2) In the medium temperature reaction stage, place the above reaction vessel in a constant temperature water bath at 32°C and stir evenly for 30 minutes;

[0064] 3) In the high-temperature reaction stage, slowly add 200ml of warm water at 50-60°C and 20ml of hydrogen peroxide with a mass concentration of 30wt% into the container after the end of the medium temperature, and finish the reaction after stirring for 30 minutes. 4 2- (with BaCl 2 solution detection), and then freeze-dried to obtain graphite oxide.

[0065] (2) Preparation of composite materials:

[0066] 1) with Pb(CH 3 COO) 2 ·3H 2 O and T...

Embodiment 3

[0074] (1) Preparation of graphite oxide (GO):

[0075] 1) In the low temperature reaction stage, add 110ml of 98wt% concentrated sulfuric acid to a dry reaction vessel, cool to 4°C, add 5g of graphite powder and NaNO while stirring 3 3.5g, after mixing evenly, slowly add 20g of potassium permanganate, control the reaction temperature at 4-10°C, and stir for 1.5h;

[0076] 2) In the medium-temperature reaction stage, place the above-mentioned reaction vessel in a constant temperature water bath at 40°C, and stir evenly for 40 minutes;

[0077] 3) In the high-temperature reaction stage, slowly add 220ml of warm water at 50-60°C and 26ml of hydrogen peroxide with a mass concentration of 30wt% into the container after the end of the medium temperature, and finish the reaction after stirring for 20 minutes. 4 2- (with BaCl 2 solution detection), and then freeze-dried to obtain graphite oxide.

[0078] (2) Preparation of composite materials:

[0079] 1) with Pb(NO3 ) 2 and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com