Directional carbon nano-tube composite cathode material for lithium-sulfur secondary battery

A carbon nanotube composite, lithium-sulfur secondary battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increased contact resistance of conductive networks and low carbon nanotube lengths, and achieves improved electrical conductivity and overcomes electrical conductivity. Insufficient rate and overcoming the effect of irregular pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation of positive electrode materials is realized by the compounding of active materials on aligned carbon nanotubes. For example, elemental sulfur can be loaded into aligned carbon nanotubes after being heated and melted by sulfur, or loaded into aligned carbon nanotubes after gasification of elemental sulfur. Aligned carbon nanotubes can be loaded in the liquid phase through a sulfur solution; sulfur / polymer composites can also be loaded with sulfur in the aligned carbon nanotubes and then composite polymers, or composite polymers in the aligned carbon nanotubes first and then The way of loading sulfur is filled into the pores of aligned carbon nanotubes. The polymer is one or more of polyaniline, polyacrylonitrile, polypyrrole, polythiophene, polyethylene oxide and polyethylene glycol. The mass ratio of the sulfur in the active material to the carbon element in the polymer is 1:0-5; the mass ratio of the carbon nanotube to the active material in the composi...

Embodiment 1

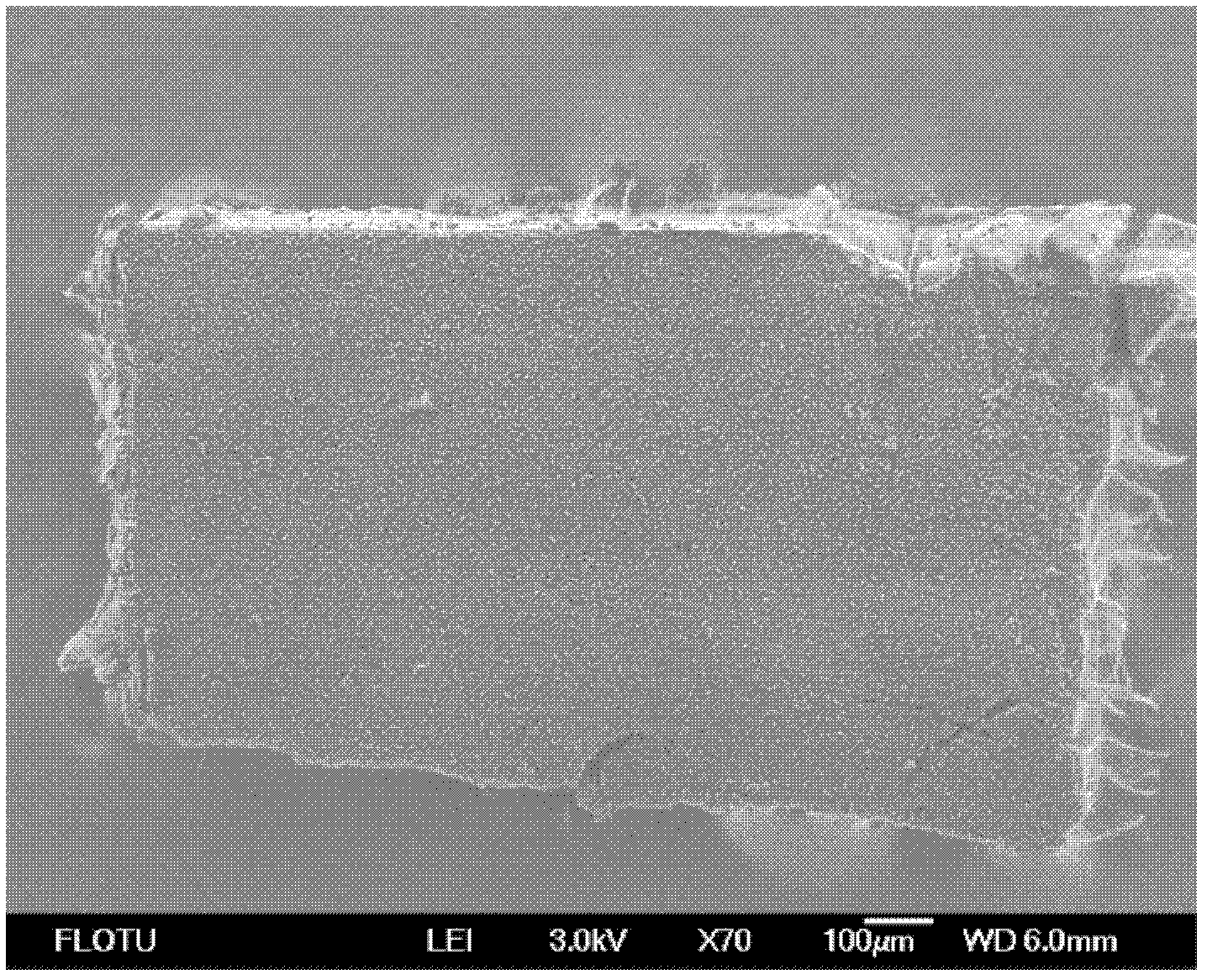

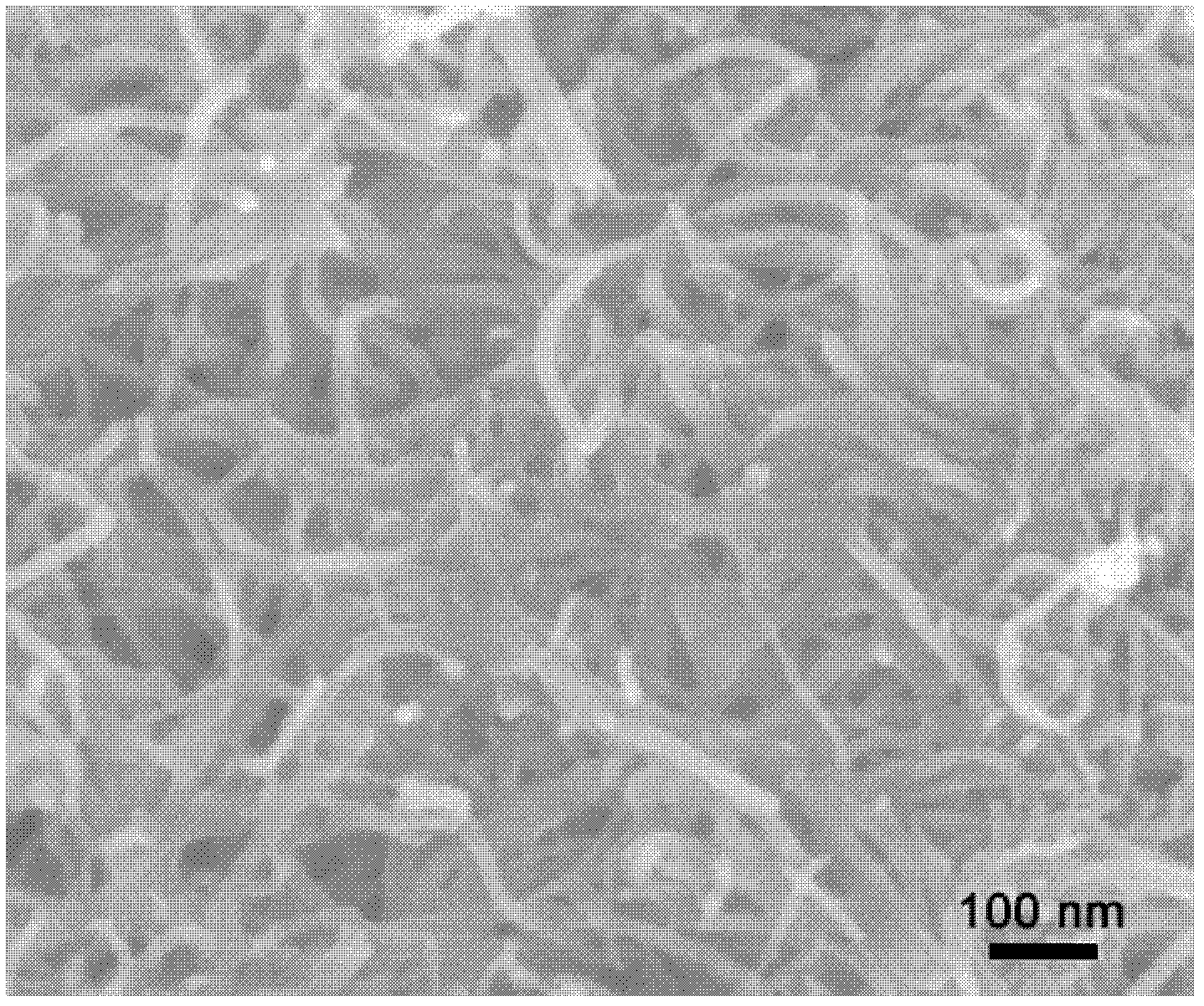

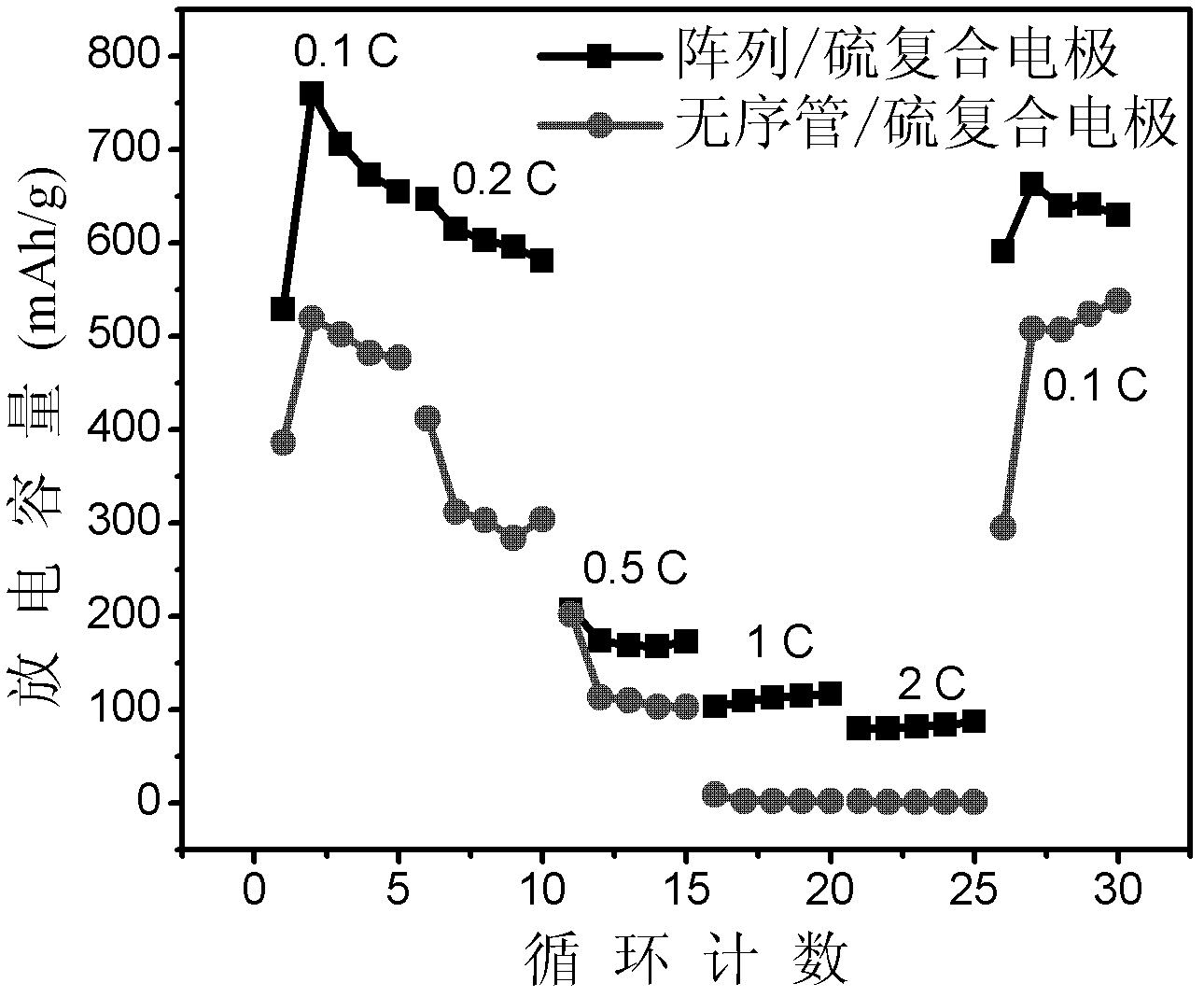

[0021] Embodiment 1: adopt thermal chemical vapor deposition process to prepare aligned carbon nanotubes on the surface of a silicon wafer coated with a catalyst, the thickness of the carbon nanotube film is about 100 microns, and the diameter of the carbon nanotubes is 8 nanometers (attached figure 1 ). The aligned carbon nanotube film was peeled off from the surface of the silicon wafer; and co-thermally composited with sublimed sulfur powder at 155°C to form a positive electrode material, and the top electron micrograph showed that sulfur was distributed between the pores of the aligned carbon nanotubes (attached figure 2 ). The mass ratio of the aligned carbon nanotubes to the active material elemental sulfur is 1:10. The disordered carbon nanotube / elemental sulfur composite material was prepared at the same mass ratio, and mixed with a binder and coated on the surface of aluminum foil as a comparative positive electrode material sample. The assembly test results show t...

Embodiment 2

[0022] Embodiment 2: Utilize planktonic chemical vapor deposition process to prepare oriented carbon nanotube film on the surface of quartz plate, the thickness of film is 1000 microns, and the carbon nanotube tube diameter in directional carbon nanotube is 100 nanometers, and approximately parallel arrangement forms array structure (attachment Figure 4 ). The aligned carbon nanotube film is separated from the quartz surface, and used as a working electrode for electrochemical deposition of polyaniline, and the prepared polyaniline is deposited in the aligned carbon nanotube. After cleaning, the aligned carbon nanotube film is impregnated with sulfur carbon disulfide solution, and the polymer is obtained after the carbon disulfide volatilizes, and the sulfur mixture is used as the positive electrode material of the active material. The material is subjected to heat treatment at 250° C. under an inert atmosphere to form bonds between the sulfur and polyaniline moieties. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com