Bilayer systems including a polydimethylglutarimide-based bottom layer and compositions thereof

A technology of dimethylglutarimide and system, which is applied in the photoplate making process of patterned surface, photosensitive materials, instruments, etc., and can solve the problems of increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

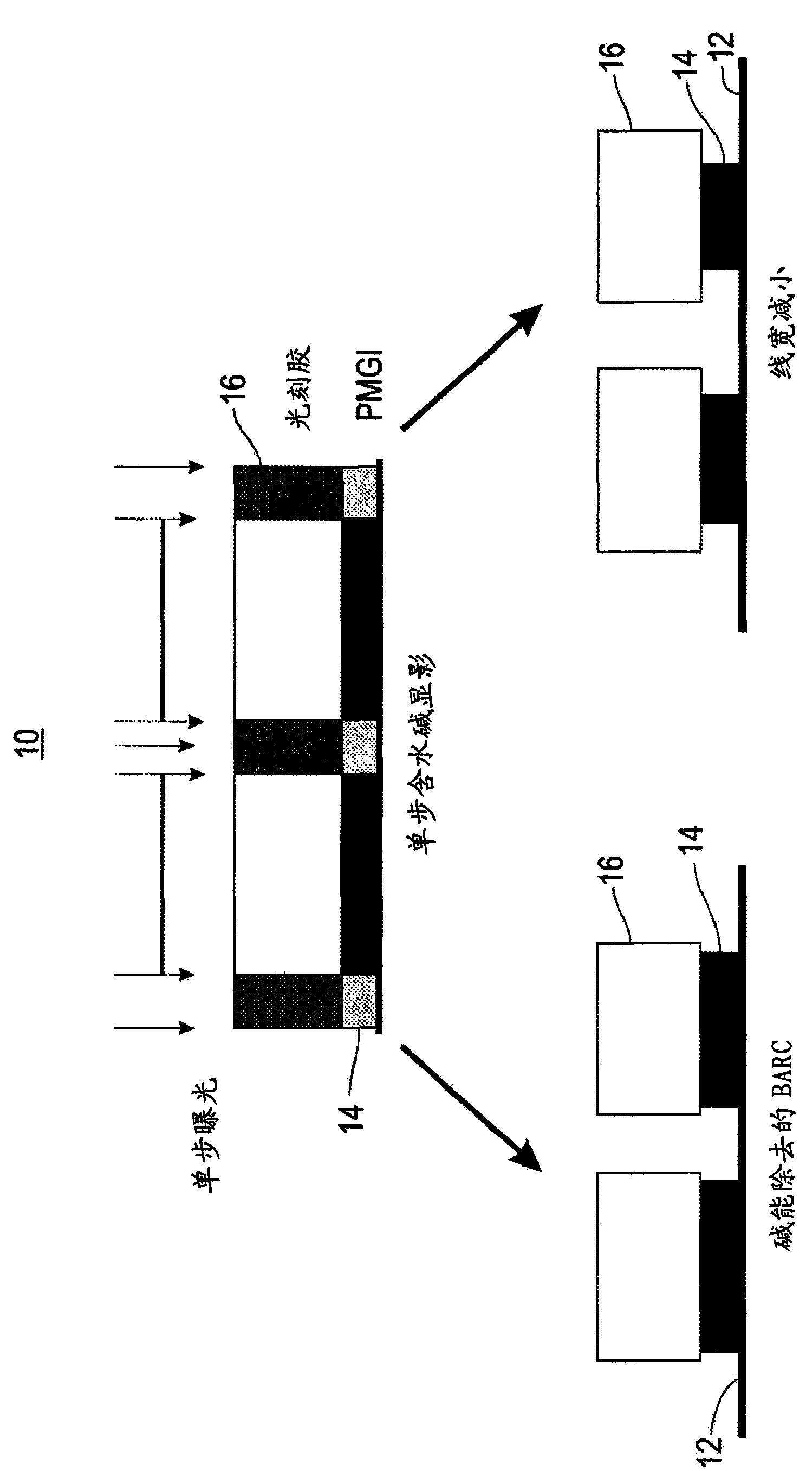

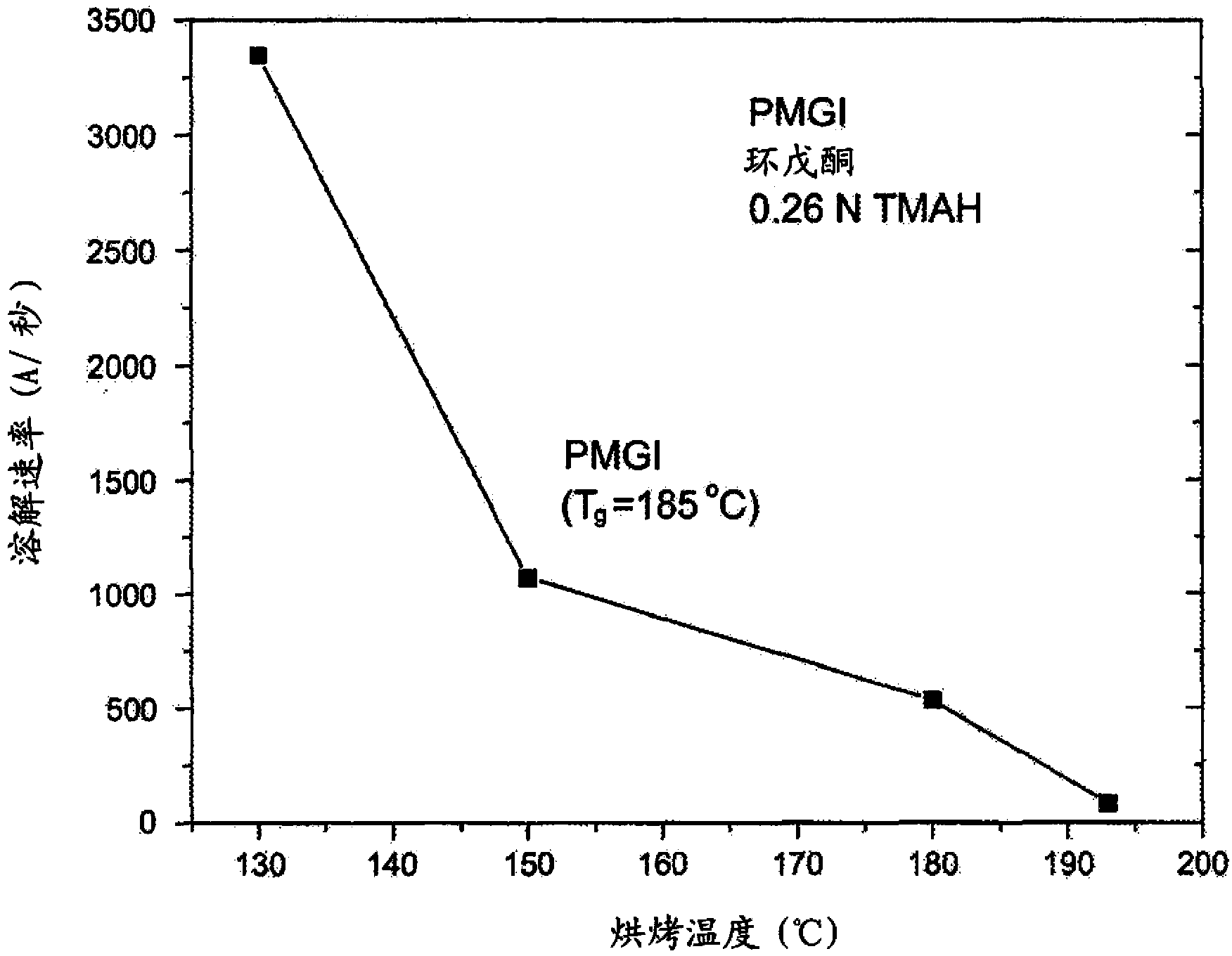

[0050] In this example, the dissolution rate of PMGI films in 0.26N tetramethylammonium hydroxide (TMAH) developer was measured as a function of bake temperature using a quartz crystal microbalance. Films were cast from solutions of PMGI and cyclopentanone. PMGI (R=CH 3 ) was synthesized in house, exhibited a glass transition temperature of 185°C, and had a number average molecular weight of 13.4 kg / mol. figure 2 The dissolution rate (Angstroms / sec) as a function of baking temperature is illustrated. As shown, PMGI itself exhibits about 3400 Angstroms / sec ( / sec) in 0.26N TMAH, and, when the bake temperature after application was increased to 150°C / 60sec, PMGI itself exhibited about Dissolution rate in 0.26N TMAH per second.

Embodiment 2

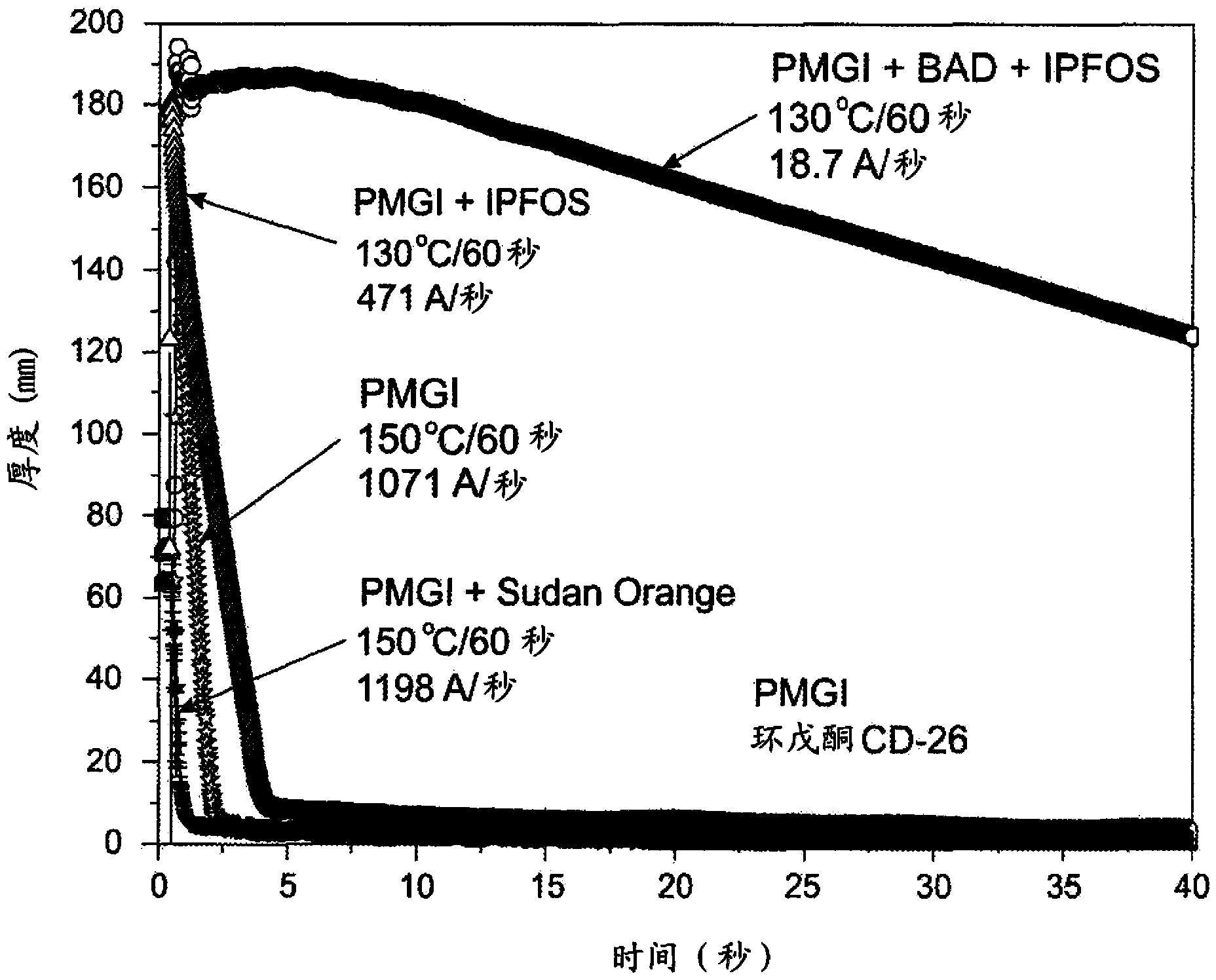

[0052] In this example, the dissolution rate of various PMGI-containing films in 0.26N TMAH developer was determined using a quartz crystal microbalance. The PMGI films were cast from cyclopentanone and included the following cast films: a.) PMGI baked at 150°C for 60 seconds; b.) PMGI baked at 130°C for 60 seconds in a ratio of 100:5 and perfluorooctane sulfonate bis-tert-butylphenyl iodide Salt PAG (IPFOS); c.) a 100:20:1 ratio of PMGI, BAD (2,5-dimethylhexan-2,5-yl-bis-adamantane -1-Carboxylate) and IPFOS; and d.) PMGI and Sudan Orange in a ratio of 100:5 baked at 150°C for 60 seconds. image 3 These results are illustrated and, moreover, show the significant effect of the acid-sensitive dissolution inhibitor (BAD) on the dissolution rate relative to other PGMI membranes without dissolution inhibitor. In addition, when comparing the dissolution rate of the PMGI cast film with the PMGI+IPFOS film, it was shown that the dissolution rate decreased when the photoacid generat...

Embodiment 3

[0054] In this example, the dissolution kinetics of exposed and unexposed PMGI films were determined. Monolayer PMGI films (100:20:1 ratio of PMGI, IPFOS, BAD baked at 130°C for 60 s) were cast and exposed to 254 nm UV radiation for 60 s or 100 s. In addition, a two-layer system was formed comprising: a top layer of silicon-containing photoresist (SCR858 from Shin-Etsu Chemical Company, Japan) optimized for 193 nm exposure, deposited at a thickness of 85 nm; and a PMGI film (at 130 A bottom layer of PMGI, IPFOS, BAD) in a ratio of 100:20:1 was baked at °C for 60 seconds. The optical density of the monolayer PMGI film at 193 nm is 3.0 / μm.

[0055] Such as Figure 4 As shown in , a significant increase in the dissolution rate was observed when the monolayer PGMI film was exposed to UV radiation ( / sec vs. / Second). Furthermore, after dissolving the top silicon-containing resist layer very quickly, the PMGI film exposed through the 193 nm silicon-containing resist dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com