Glimepiride nano-particle capsule and preparation method thereof

A technology of glimepiride and nanoparticles, applied in the field of medicine, can solve the problems of poor water solubility of glimepiride, poor effect of targeted therapy, and low bioavailability, and achieve improved bioavailability, good effect, and half-life of the drug prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

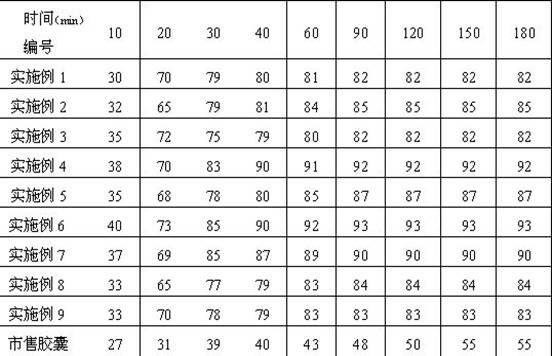

Examples

preparation example Construction

[0013] The preparation method of the glimepiride nanoparticle capsule of the present invention comprises the following steps:

[0014] (1) Preparation of primary suspension: dissolving glimepiride or the mixture of glimepiride and the surfactant in an organic solvent, the volume concentration of the organic solvent is 10-70% (v / v ), the selected organic solvent is methanol, ethanol, acetonitrile, ether, acetone, isopropanol, ethyl acetate, dichloromethane or a mixed solution of two equal volumes. When the drug cannot be completely dissolved, It can be heated and dissolved at 40-60°C, and the initial suspension can be prepared by high-speed homogenization method, magnetic stirring method, or ultrasonic method;

[0015] The high-speed homogenization method is: dissolving the surfactant in ultrapure water to make a water phase containing the surfactant, and adding the water phase containing the surfactant to the In the organic solvent of urea, use an internal cutting type homoge...

Embodiment 1

[0025] Weigh 20mg of glimepiride and 150mg of soybean lecithin, add 10ml of acetone to ultrasonically dissolve to form an organic phase; weigh 150mg of PVP-K30 and dissolve in 20ml of ultrapure water to form an aqueous phase. Heat the organic phase and the aqueous phase in a water bath at 40-60°C for 3 minutes, add the aqueous phase to the organic phase, and use an internal cutting homogenizer at 15,000 rpm to homogenize for 5 minutes to obtain an initial suspension; The suspension was rotated under reduced pressure at room temperature to remove the organic solvent, then placed on a high-pressure homogenizer, and circulated 15 times at 9k psi and 18k psi each to obtain a milky white nanosuspension; 1000mg of xylitol was dissolved in the nanomixer suspension, put it in a -80°C refrigerator for 6 hours, and then place it in a freeze dryer at a temperature and pressure of -84°C and 98×10 -3 Under the condition of Mbar, dry for 24 hours to prepare glimepiride nanoparticle freeze-...

Embodiment 2

[0028] Weigh 50 mg of glimepiride, add 10 ml of acetone to ultrasonically dissolve to form an organic phase; weigh 450 mg of PEG6000 and dissolve in 20 ml of ultrapure water to form an aqueous phase. Heat the organic phase and the aqueous phase in a water bath at 50°C for 10 minutes, add the aqueous phase to the organic phase, and homogenize with an internal cutting homogenizer at 15,000 rpm for 5 minutes to obtain a primary suspension. Then the primary suspension was rotated under reduced pressure at normal temperature to remove the organic solvent, and then placed on a high-pressure homogenizer, and circulated 18 times under 9k psi and 18k psi to obtain a milky white nano-suspension; mannitol and xylitol After mixing according to the ratio of 1:1, weigh 1500mg and dissolve it in the nano-suspension, put it in a -20 ℃ refrigerator for 12 hours, and then place it in a freeze dryer. ×10 -3 Under the condition of Mbar, dry for 12 hours to prepare glimepiride nanoparticle freeze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com