Compound preparation of glucosamine chondroitin and production method of compound preparation

A technology of compound preparation and production method, which is applied in medical preparations containing active ingredients, food preparation, pill delivery, etc., can solve problems such as softening of cartilage matrix, increase of cartilage surface cavities, and obstruction of GS synthesis, and achieve good compressibility Sex and stability, improve product quality, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

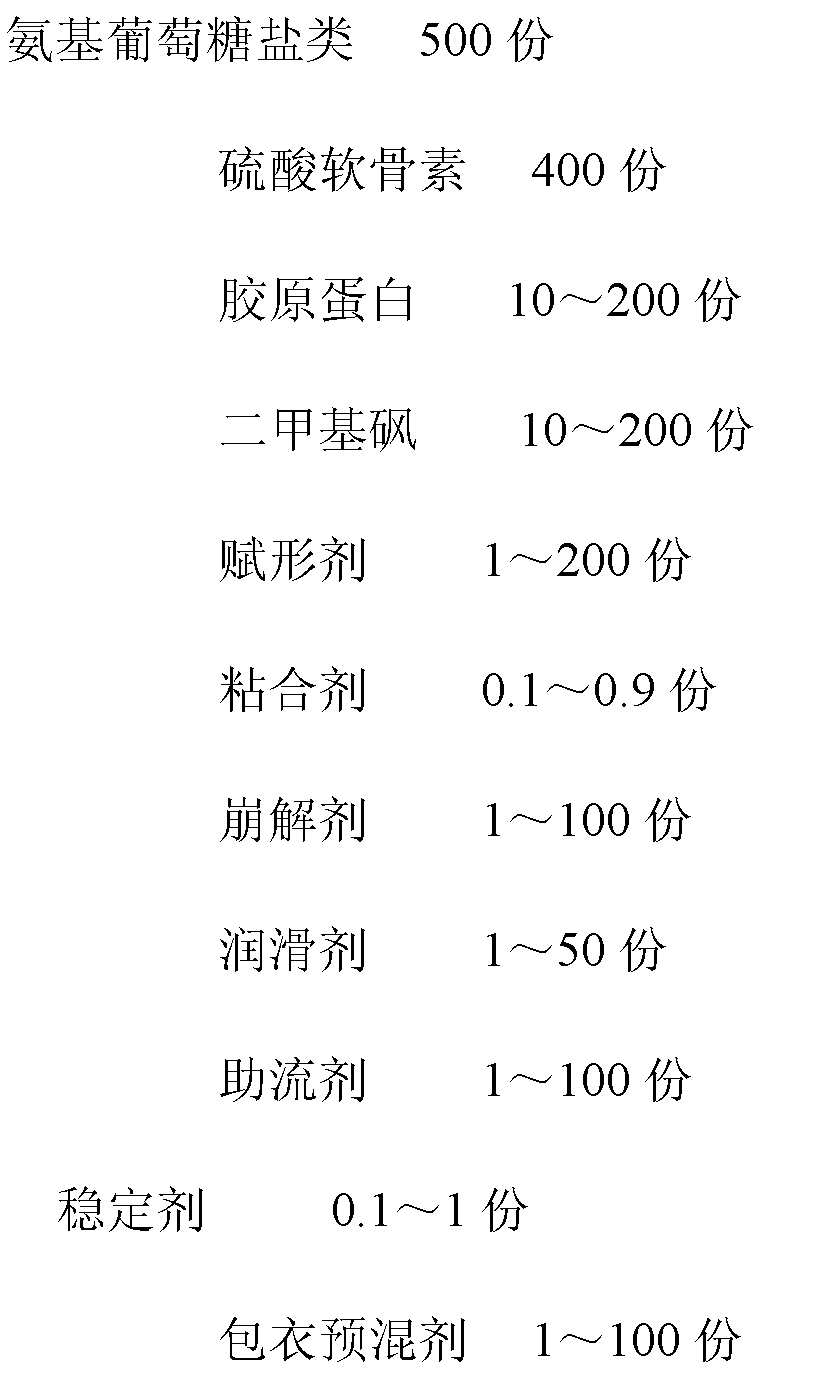

Image

Examples

Embodiment 1

[0042] Example 1: Preparation of compound preparation of glucosamine salts and chondroitin sulfate (5:4)

[0043] Glucosamine Hydrochloride 1500g

[0044] Chondroitin Sulfate 1200g

[0045] Microcrystalline Cellulose 120g

[0046] Sodium carboxymethyl starch 45g

[0047] Sodium Carboxymethyl Cellulose 1.5g

[0048] Tartaric acid 0.5g

[0050] Appropriate amount of water

[0051] Coating Premix 40g

[0052] Prepare as follows:

[0053] 1. Mix the adhesive and stabilizer, use an appropriate amount of water to prepare an adhesive solution with a concentration of 0.1-5%, fully dissolve until clear and transparent, crush the raw materials, pass through a 60-120 mesh sieve, and mix glucosamine and an appropriate amount Chondroitin sulfate (accounting for 3 to 10%) is put into a wet granulator and stirred for 1 to 10 minutes, mixed evenly, uniformly and slowly added to the prepared binder solution, adding liquid while stirring to make granules,...

Embodiment 2

[0057] Example 2: Preparation of Compound Preparation of Glucosamine Salts and Chondroitin Sulfate (5:4)

[0058] Glucosamine Sulfate Potassium Salt 750g

[0059] Chondroitin Sulfate 600g

[0060] Collagen 150g

[0061] Microcrystalline Cellulose 120g

[0062] Sodium carboxymethyl starch 45g

[0063] Hydroxypropyl methylcellulose 0.5g

[0064] Sodium carboxymethylcellulose 0.5g

[0065] Tartaric acid 0.5g

[0067] Appropriate amount of water

[0068] Coating Premix 40g

[0069] Prepare as follows:

[0070] 1. Mix the adhesive and stabilizer, use an appropriate amount of water to prepare an adhesive solution with a concentration of 0.1-5%, fully dissolve until clear and transparent, crush the raw materials, pass through a 60-120 mesh sieve, and mix glucosamine and an appropriate amount Put chondroitin sulfate (3-10%) into the wet granulator and stir for 1-10 minutes, mix well, evenly and slowly add the prepared binder solution, add liqu...

Embodiment 3

[0074] Example 3: Preparation of Compound Preparation of Glucosamine Salts and Chondroitin Sulfate (5:4)

[0075] Glucosamine Hydrochloride 500g

[0076] Chondroitin Sulfate 400g

[0077] Collagen 150g

[0078] Dimethylsulfone 150g

[0079] Microcrystalline Cellulose 120g

[0080] Sodium carboxymethyl starch 45g

[0081] Sodium carboxymethylcellulose 0.8g

[0082] Tartaric acid 0.5g

[0084] Appropriate amount of water

[0085] Coating Premix 40g

[0086] Prepare as follows:

[0087] 1. Mix the adhesive and stabilizer, use an appropriate amount of water to prepare an adhesive solution with a concentration of 0.1-5%, fully dissolve until clear and transparent, crush the raw materials, pass through a 60-120 mesh sieve, and mix glucosamine and an appropriate amount Put chondroitin sulfate (3-10%) into the wet granulator and stir for 1-10 minutes, mix well, evenly and slowly add the prepared binder solution, add liquid while stirring to gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com