Nanometer composite epoxy resin self-repairing microcapsule and preparation method thereof

A technology for self-healing microcapsules and epoxy resins, applied in microcapsule preparations, microsphere preparations, etc., can solve the problems of low encapsulation efficiency, unstable thermodynamics and dynamics of emulsion droplets, and inability to provide structural stability, etc. The effect of improving mechanical strength and thermal stability, improving repair efficiency, and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

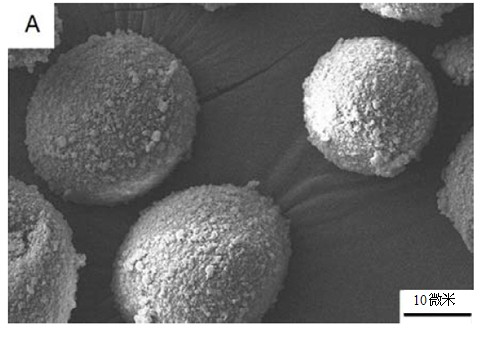

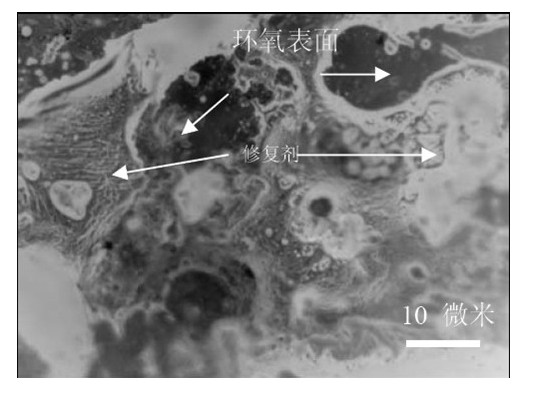

[0023] 50 mg of fumed silica nanoparticles were ultrasonically dispersed in 5 ml of deionized water, and 50 mg of PPG-TDI was shaken and dissolved in 5 ml of ethyl phenylacetate. The oil-water phase is mixed, shaken and emulsified by hand to obtain an oil-in-water Pickering emulsion stabilized by silica nanoparticles. Add 3.35ml of 37 wt% formaldehyde solution, 2ml of triethanolamine, 10ml of water and 1.75g of melamine to a 50ml two-necked flask in turn, and stir magnetically at 60°C for 30min to obtain an aqueous solution of melamine-formaldehyde prepolymer. Add the oil-in-water Pickering emulsion obtained above dropwise into the aqueous solution of melamine-formaldehyde prepolymer, adjust the pH to 4 with acetic acid, heat to 50 °C at a heating rate of 5 °C / min, mechanically stir at 400 rpm, and react for 4 h . Cool down to room temperature at a rate of 2°C / min. The resulting suspension was washed three times with water, filtered, and dried at room temperature for 24 h ...

Embodiment 2

[0025]37.5 mg of fumed silica nanoparticles were ultrasonically dispersed in 5 ml of deionized water, and 5 mg of PPG-TDI was shaken and dissolved in 5 ml of ethyl phenylacetate. The oil-water phase is mixed, shaken and emulsified by hand to obtain an oil-in-water Pickering emulsion stabilized by silica nanoparticles. Add 3.35ml of 37 wt% formaldehyde solution, 2ml of triethanolamine, 10ml of water and 1.75g of melamine to a 50ml two-necked flask in turn, and stir magnetically at 60°C for 30min to obtain an aqueous solution of melamine-formaldehyde prepolymer. Add the oil-in-water Pickering emulsion obtained above dropwise into the aqueous solution of melamine-formaldehyde prepolymer, adjust the pH to 3 with acetic acid, heat to 60 °C at a heating rate of 5 °C / min, mechanically stir at 200 rpm, and react for 3 h . Cool down to room temperature at a rate of 2°C / min. The resulting suspension was washed three times with water, filtered, and dried at room temperature for 24 h ...

Embodiment 3

[0027] 25 mg of fumed silica nanoparticles were ultrasonically dispersed in 5 ml of deionized water, and 100 mg of PPG-TDI was shaken and dissolved in 5 ml of ethyl phenylacetate. The oil-water phase is mixed, shaken and emulsified by hand to obtain an oil-in-water Pickering emulsion stabilized by silica nanoparticles. Add 3.35ml of 37 wt% formaldehyde solution, 2ml of triethanolamine, 10ml of water and 1.75g of melamine to a 50ml two-necked flask in turn, and stir magnetically at 60°C for 30min to obtain an aqueous solution of melamine-formaldehyde prepolymer. Add the oil-in-water Pickering emulsion obtained above dropwise into the aqueous solution of melamine formaldehyde prepolymer, adjust the pH to 5 with acetic acid, heat to 40°C at a heating rate of 5°C / min, and mechanically stir at 600 rpm, and react for 5zz h . Cool down to room temperature at a rate of 2°C / min. The resulting suspension was washed three times with water, filtered, and dried at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com