Method for welding foam aluminum sandwich composite plate

A sandwich composite panel and welding method technology, which is applied in the field of aluminum plate welding, can solve the problems of large influence of environmental factors, easy aging of adhesives, complicated process, etc., and achieve low labor intensity, low welding cost and good environmental adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

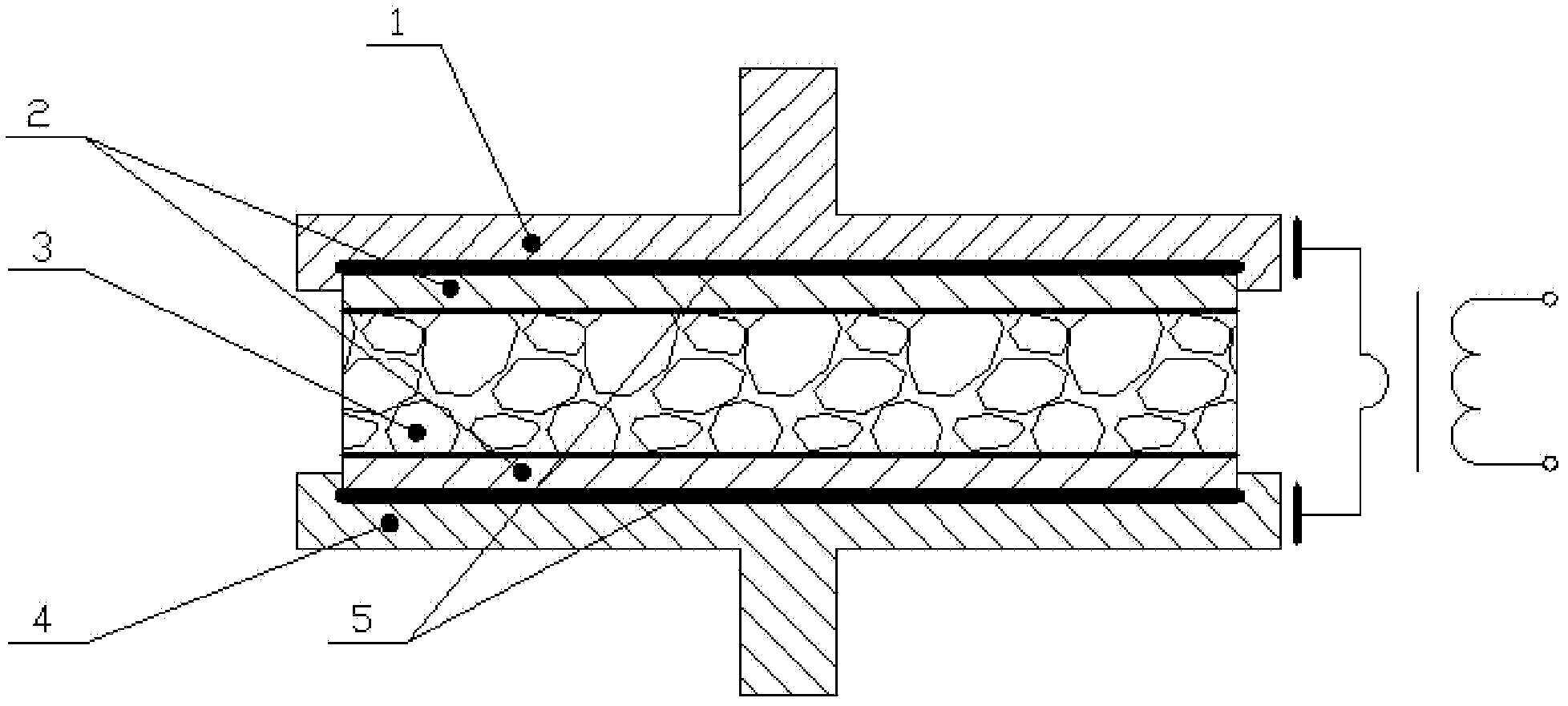

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but does not impose any limitation on the present invention. A welding method for aluminum foam sandwich composite panels, comprising the following steps:

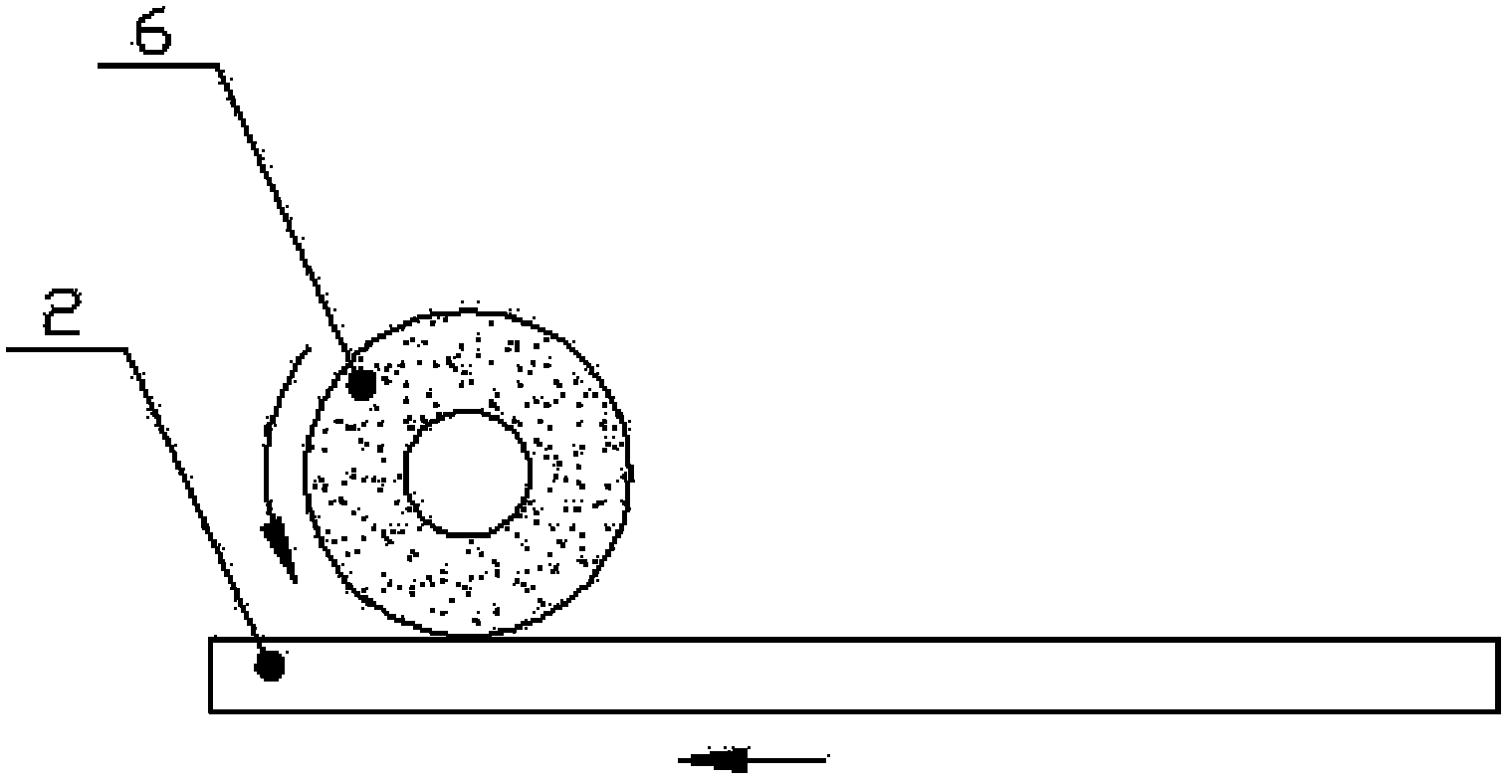

[0028] 1) Cut two aluminum plates with a size of 200mmx50mmx5mm as the panel 2, and draw one side of the panel 2 with a 60# drawing wheel 6 to form a uniform rough surface, see figure 2 and image 3 ; Then use the surface milling method to remove the oxide film on the other side of the panel 2; then wipe the milling surface with clean cotton yarn dipped in absolute alcohol, and after drying, apply a 0.2mm thick conductive paste 5; finally process The two good panels 2 are fixed on the conductive fixture after cleaning and drying, and fixed to ensure that the surface coated with the conductive paste 5 is closely attached to the conductive fixture;

[0029] 2) Cut the block aluminum foam into a size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com