Glass used for absorbing optical spectrum with wavelength being 430-900nm for optical fiber panel and preparation process thereof

A technology of optical fiber panel and wavelength, which is applied in the field of glass for optical fiber panel absorbing 430-900nm wavelength spectrum and its preparation process, which can solve the problems of inability to play stray light and poor anti-devitrification performance, and achieve anti-analysis Good crystal performance, high glass gloss, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

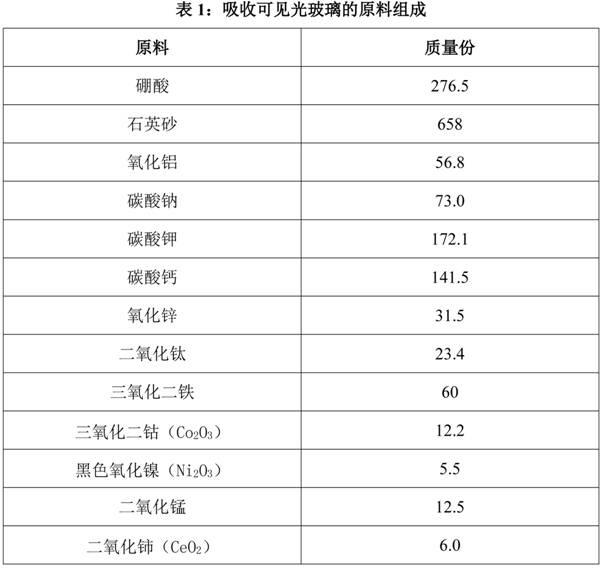

[0016] A glass that absorbs the 430-900nm wavelength spectrum for an optical fiber panel is made of the following raw materials in parts by mass:

[0017]

[0018] The glass sheet (thickness is 0.40±0.01mm) made of the raw materials in Example 1, after testing, the spectral transmittance of 430-900nm is ≤5.0%, the softening temperature is 600-640°C, and it is kept at 820°C for 2 hours Does not crystallize.

Embodiment 2

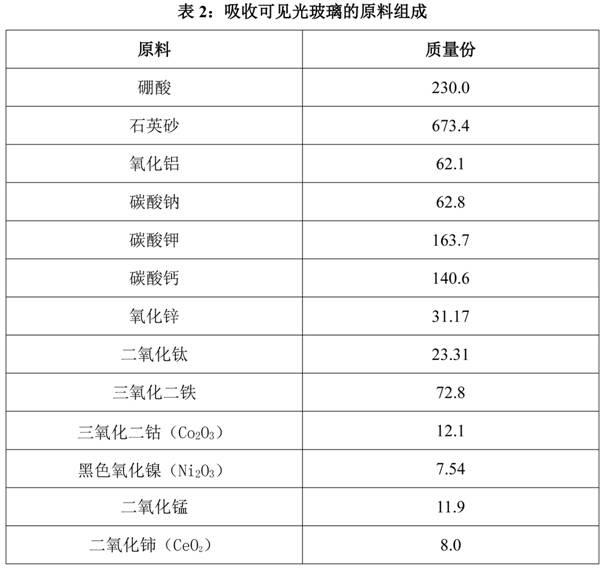

[0020] A glass that absorbs the 430-900nm wavelength spectrum for an optical fiber panel is made of the following raw materials in parts by mass:

[0021]

[0022] The glass sheet (thickness is 0.40±0.01mm) made of the raw materials in Example 2, after testing, the spectral transmittance of 430-900nm is ≤4.0%, the softening temperature is 650-700°C, and it is kept at 820°C for 2 hours Does not crystallize.

Embodiment 3

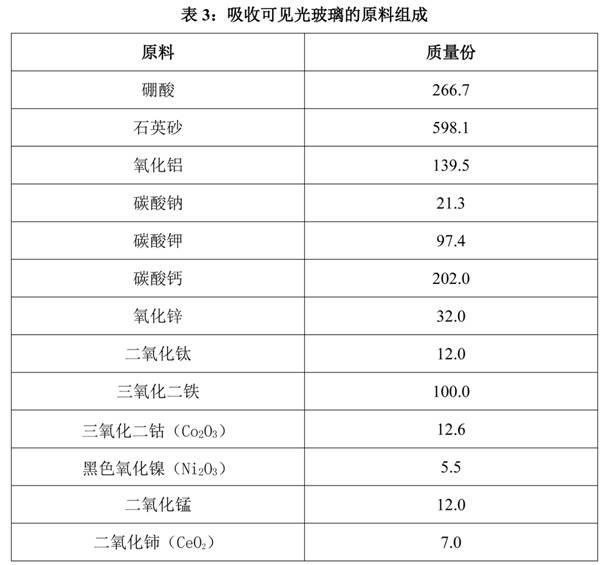

[0024] A glass that absorbs the 430-900nm wavelength spectrum for an optical fiber panel is made of the following raw materials in parts by mass:

[0025]

[0026] The glass sheet (thickness is 0.40±0.01mm) made of the raw materials in Example 3, after testing, the spectral transmittance of 430-900nm is ≤5.0%, the softening temperature is 630-660°C, and it is kept at 820°C for 2 hours Does not crystallize.

[0027] The particle size of the quartz sand used in the present invention is 80-100 mesh, produced in Jiangsu Donghai Shihu Quartz Sand General Factory.

[0028] The preparation technology of glass of the present invention is:

[0029] (1) Add the raw materials into the crucible at 1370-1390°C; (2) After the feeding is completed, it takes 25-35 minutes to raise the temperature to the clarification temperature of 1450°C; the clarification time is 6-7h; (3) After the clarification is completed, cast in the mold It is a glass rod, and the pouring temperature is 1440-1460...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com