Biodegradable polylactic acid-starch flame retardant composite material and preparation method thereof

A flame-retardant composite material and flame-retardant composite technology, applied in the field of polymer materials, can solve the problems of high price and high brittleness of polylactic acid, achieve good mechanical properties, improve compatibility, and improve material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

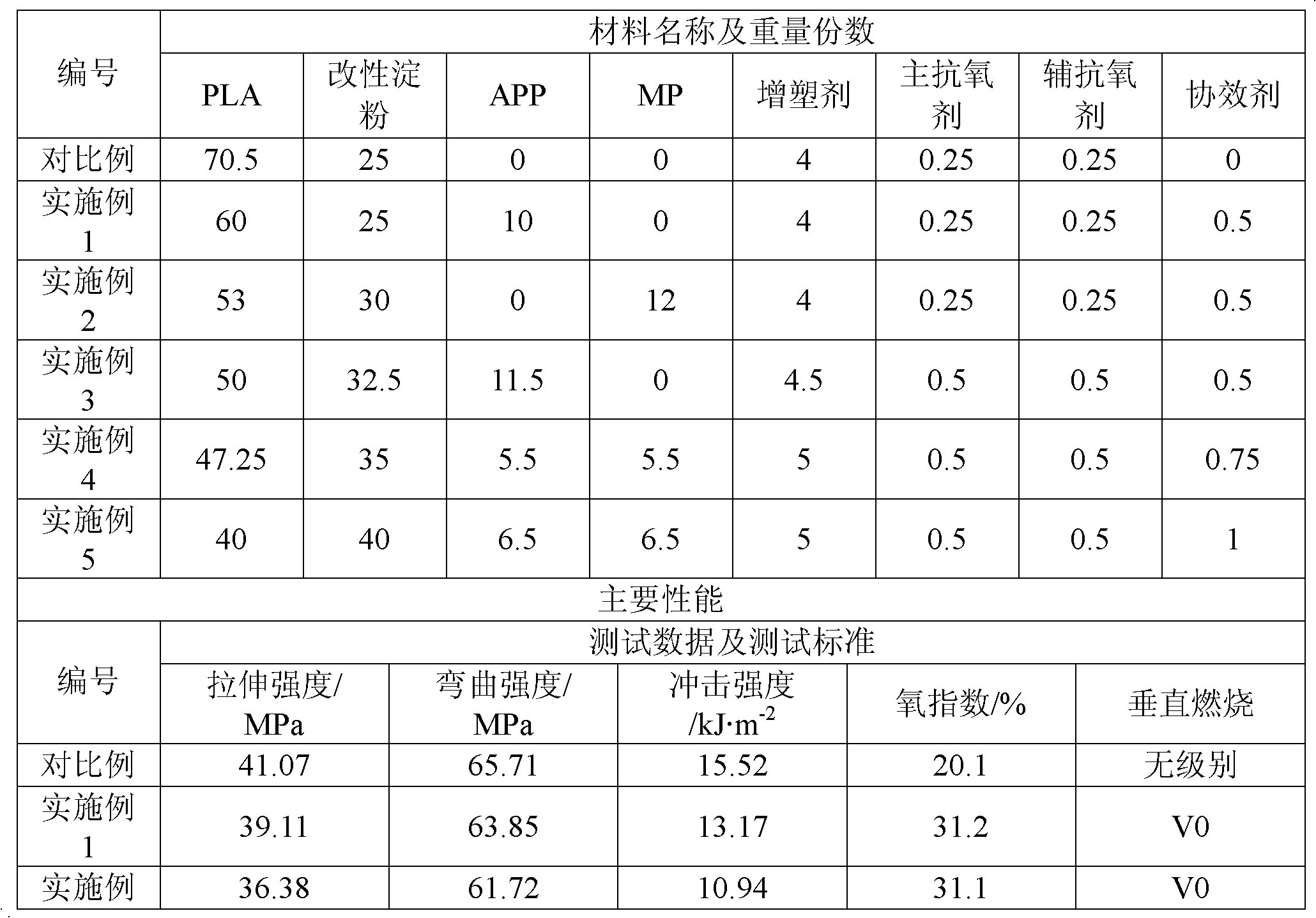

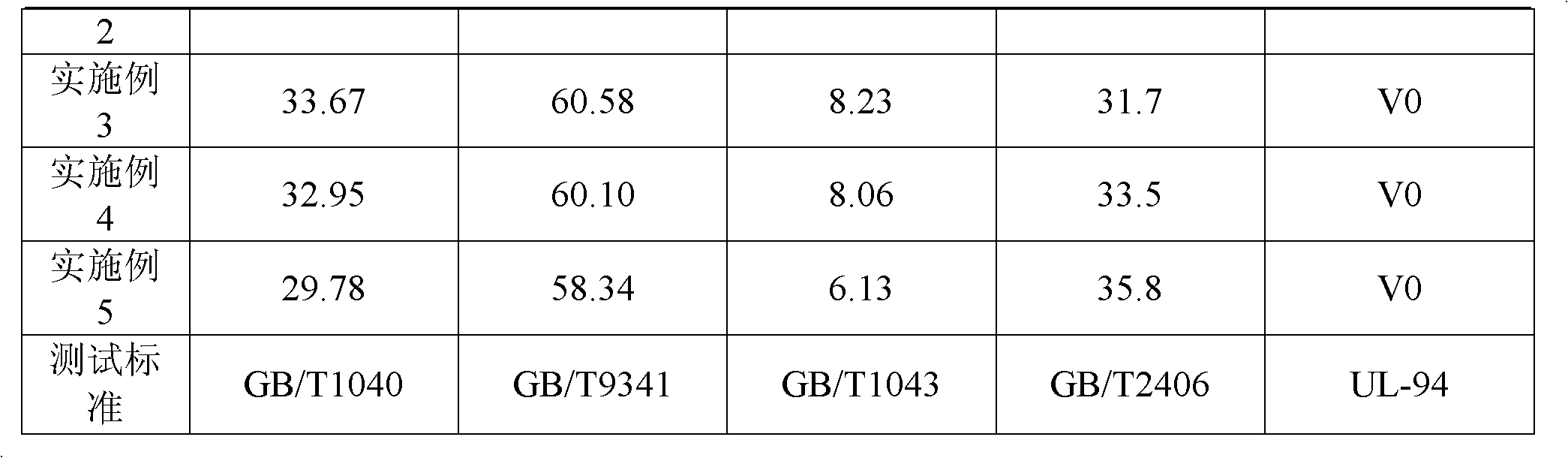

Embodiment 1

[0041]Put 96.5 parts of starch (corn starch) into a high-speed mixer after drying, add 2 parts of maleic anhydride and 0.5 part of benzoyl peroxide to carry out grafting reaction at 70 ° C for 30 minutes, and obtain grafted branched starch; then add 1 part of stearic acid to the grafted starch for surface modification at 60° C. for 30 minutes to obtain grafted modified starch.

[0042] The preparation process of the biodegradable polylactic acid-starch flame-retardant composite material is as follows: 60 parts of polylactic acid, 25 parts of modified starch, 10 parts of ammonium polyphosphate, 4 parts of polyethylene glycol 6000, 0.25 parts of antioxidant 1010, 0.25 168 parts of antioxidant, 0.5 part of zinc stannate are put into a high-speed mixer, mixed for 5 minutes at room temperature and taken out; the above-mentioned homogeneously mixed blend is melted and extruded by a twin-screw extruder, cooled, granulated, and The obtained polylactic acid-starch flame-retardant compo...

Embodiment 2

[0045] In parts by mass, put 95 parts of starch (sweet potato starch) into a high-speed mixer after drying, add 2.5 parts of maleic anhydride and 0.5 parts of benzoyl peroxide to carry out grafting reaction at 70 °C for 30 minutes to obtain grafted starch; then add 2 parts of stearic acid to the grafted starch for surface modification at 60° C. for 30 minutes to obtain grafted modified starch.

[0046] The preparation process of the biodegradable polylactic acid-starch flame-retardant composite material is as follows: 53 parts of polylactic acid, 30 parts of modified starch, 12 parts of melamine phosphate, 4 parts of polyethylene glycol 6000, 0.25 parts of antioxidant 1010, 0.25 168 parts of antioxidant and 0.5 part of 4A molecular sieves were put into a high-speed mixer, mixed for 7 minutes at room temperature and taken out; the above-mentioned homogeneously mixed blend was melted and extruded through a twin-screw extruder, cooled and granulated, and obtained The polylactic a...

Embodiment 3

[0049] In parts by mass, put 94 parts of starch (wheat starch) into a high-speed mixer after drying, add 2.5 parts of maleic anhydride and 0.5 parts of benzoyl peroxide to carry out grafting reaction at 70°C for 30 minutes to obtain grafted starch; then add 3 parts of stearic acid to the grafted starch for surface modification at 60° C. for 30 minutes to obtain grafted modified starch.

[0050] The preparation process of the biodegradable polylactic acid-starch flame-retardant composite material is as follows: 50 parts of polylactic acid, 32.5 parts of modified starch, 11.5 parts of ammonium polyphosphate, 4.5 parts of polyethylene glycol 6000, 0.5 parts of antioxidant 1010, 0.5 168 parts of antioxidant and 0.5 part of zinc borate were put into a high-speed mixer, mixed for 8 minutes at room temperature and taken out; the above-mentioned homogeneously mixed blend was melted and extruded through a twin-screw extruder, cooled and granulated, and obtained The polylactic acid-star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com