Brewing yeast engineering bacteria containing Lg-ATF1 genes

A technology of Saccharomyces cerevisiae and engineering bacteria, which is applied in the field of bioengineering and can solve the problems of low ester production capacity of Saccharomyces cerevisiae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

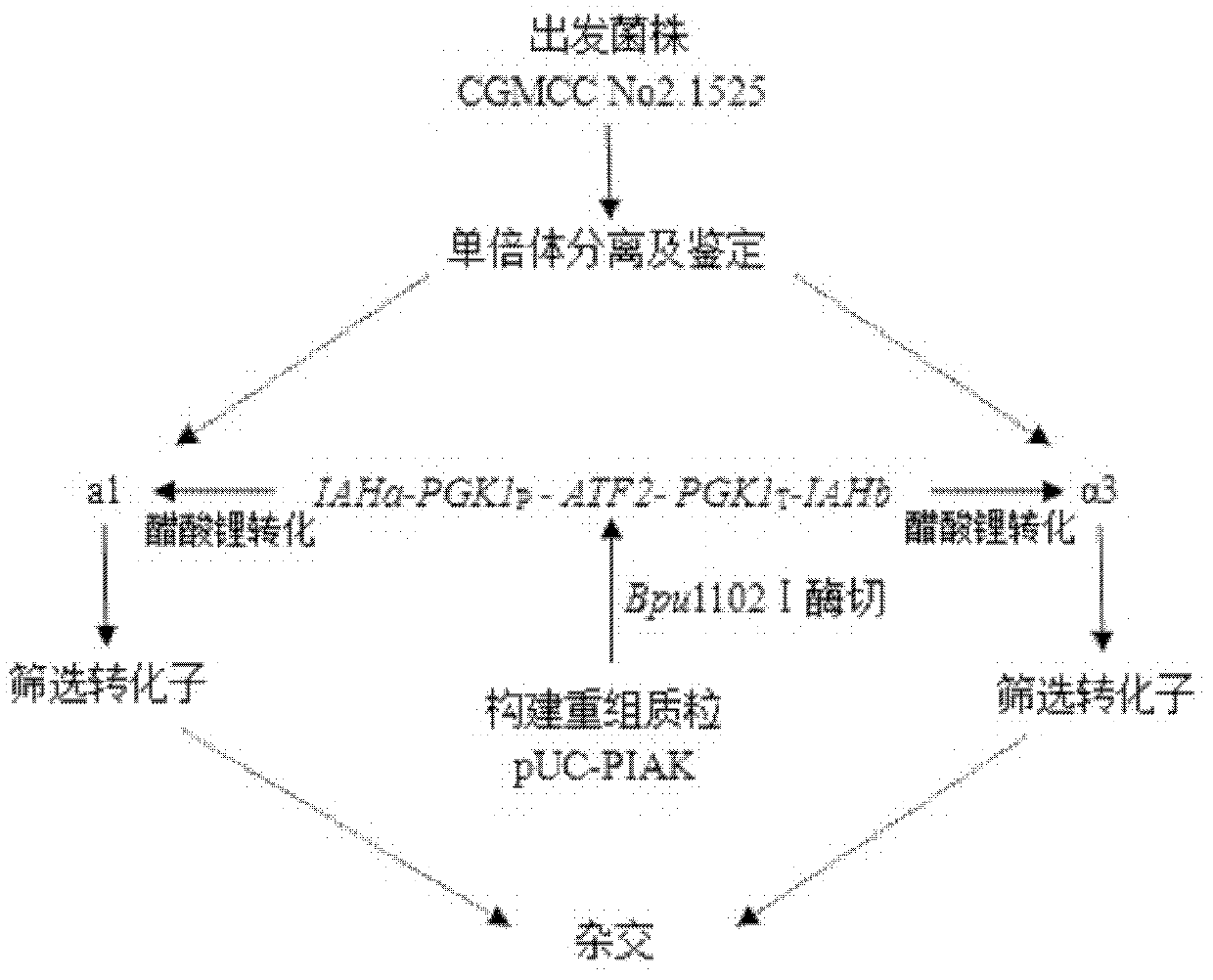

[0027] Embodiment 1: Containing the construction of the Saccharomyces cerevisiae engineered bacteria of Lg-ATF1 gene

[0028] (1) Construction of genetic engineering strains

[0029] 1) Ligate the PGK1 promoter and terminator with the pUC19 plasmid to obtain pUC-PGK1;

[0030] 2) Ligate the homologous fragment IAH derived from Saccharomyces cerevisiae to the pUC-PGK1 obtained in step 1) to obtain pUC-PGK1-IAH;

[0031] 3) Inserting the gene encoding alcohol acetyltransferase Lg-ATF1 in Saccharomyces cerevisiae into the pUC-PGK1-IAH obtained in step 2) between the PGK1 promoter and terminator to obtain pUC-PGK1-IAH-Lg-ATF1;

[0032] 4) connecting the kan gene to the pUC-PGK1-IAH-Lg-ATF1 obtained in step 3) to obtain the plasmid pUC-PGK1-IAH-Lg-ATF1-kan (hereinafter referred to as pUC-PILgK);

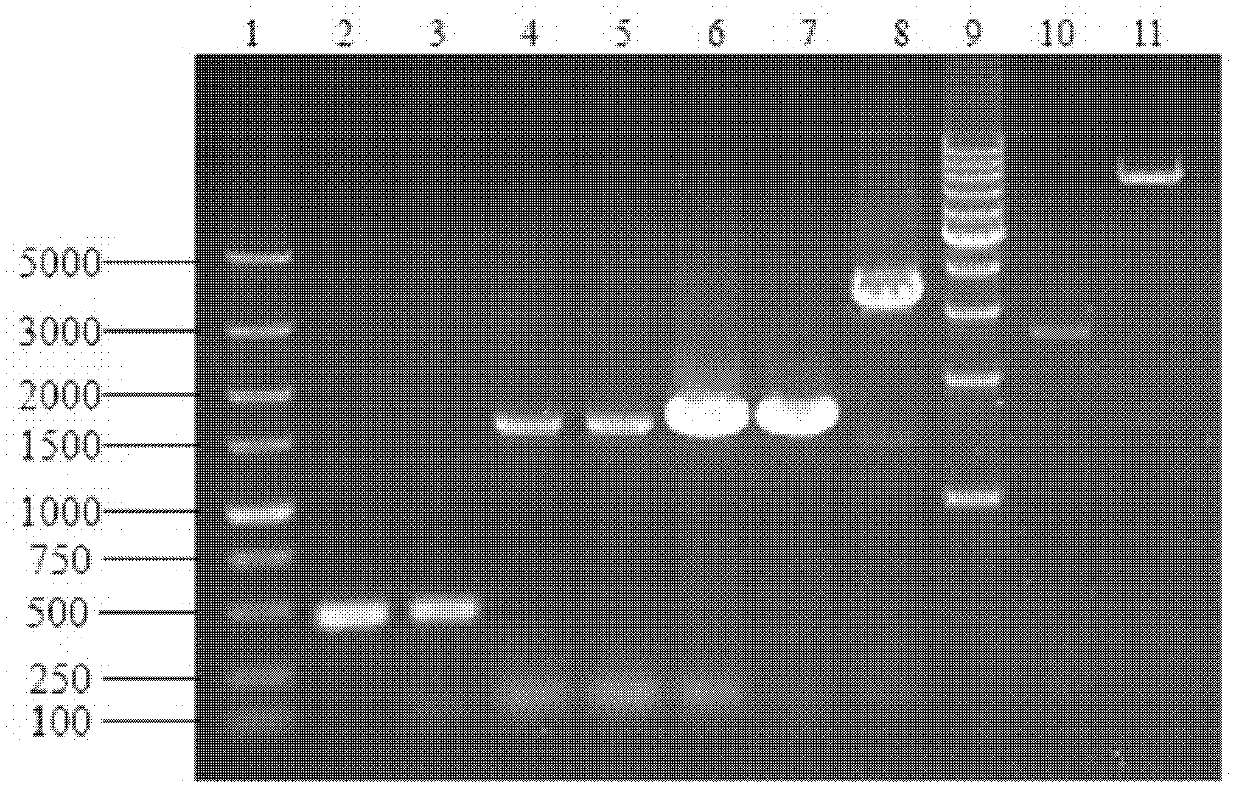

[0033] figure 1 The verification electropherogram of the pUC-PILgK plasmid: Lane 1 is the 5000 bp DNA Ladder Marker; Lane 2 is the homologous fragment IAH amplified by PCR from the gen...

Embodiment 2

[0042] Example 2: Research on the fermentation performance of Saccharomyces cerevisiae engineering bacteria and starting strains containing Lg-ATF1 gene

[0043] The engineering bacteria and the recipient bacteria were respectively inserted into 5mL wort culture solution, and cultured overnight at 30°C for 12h; all the bacterial liquids were transferred to 20mL fresh wort culture liquid, and cultured at 30°C for 24h. Take 100g of japonica rice and place it in water at 25-30°C for 72 hours; take it out, wash it, and cook it under normal pressure for 30 minutes. Cool the rice, put it into a 500mL conical flask, add 10g of cooked wheat koji and 105mL of water. Finally, 25 mL of yeast wort culture liquid was inserted and fermented at 28° C. for 5 days. Shake and weigh every 12 hours during the fermentation period, and record the weight loss; after the fermentation is over, stop the cultivation and weigh; measure the residual sugar concentration, alcohol volume fraction and main a...

Embodiment 3

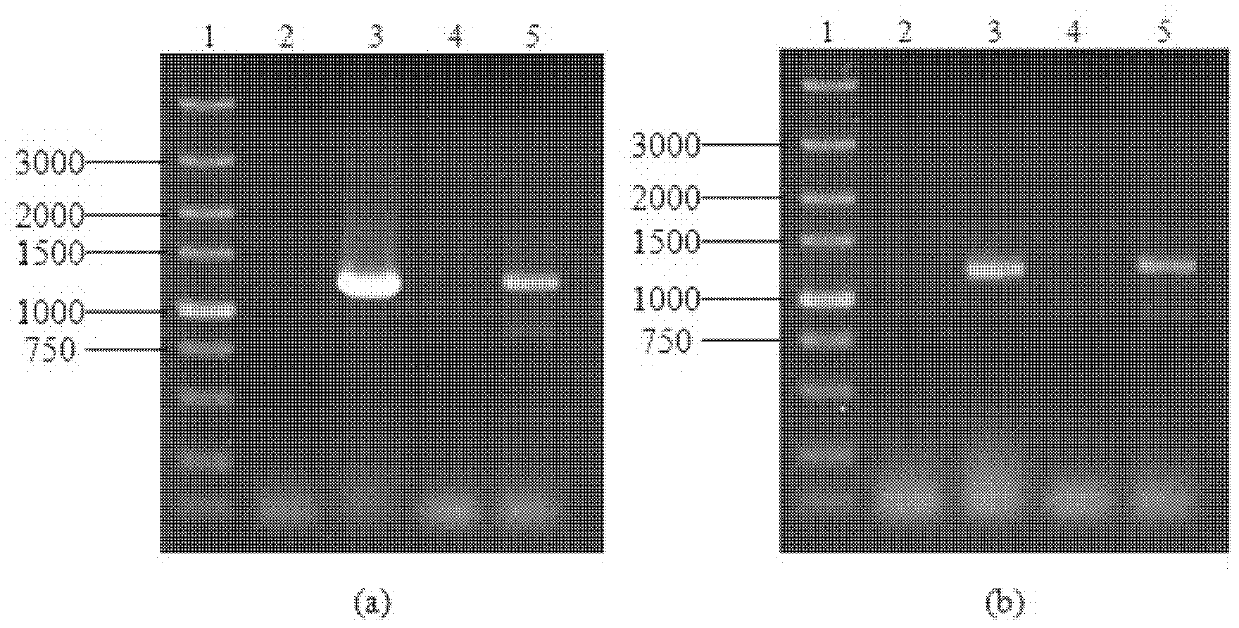

[0047] Example 3: Research on the fermentation performance of engineering haploids containing the Lg-ATF1 gene and the haploids of the starting strain

[0048] Put the engineering haploid (type a / α) and the haploid of the recipient bacteria (type a / α) into 5mL wort culture solution, culture overnight at 30°C for 12h; transfer all the bacteria solution to 20mL fresh wort Incubate at 30°C for 24 hours in the culture medium. Take 100g of japonica rice and place it in water at 25-30°C for 72 hours; take it out, wash it, and cook it under normal pressure for 30 minutes. Cool the rice, put it into a 500mL conical flask, add 10g of cooked wheat koji and 105mL of water. Finally, 25 mL of yeast wort culture liquid was inserted and fermented at 28° C. for 5 days. Shake and weigh every 12 hours during the fermentation period, and record the weight loss; after the fermentation is over, stop the cultivation and weigh; measure the residual sugar concentration, alcohol volume fraction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com