Preparation method of natural polyelectrolyte-based core-shell structured nano-fiber

A polyelectrolyte, nanofiber technology, applied in the direction of chemical characteristics of fibers, pharmaceutical formulations, conjugated synthetic polymer man-made filaments, etc., to achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolving hyaluronic acid with a molecular weight of 5000g / mol in water to prepare a solution with a weight percentage of 10wt%, and then fully stirring the solution so as to completely dissolve to obtain a hyaluronic acid solution.

[0024] (2) Dissolving polyoxyethylene in water to prepare a solution with a weight percentage of 4wt%, and then fully stirring the solution so as to completely dissolve to obtain a polyoxyethylene solution. The hyaluronic acid solution and the polyoxyethylene solution are mixed according to a volume ratio of 1:1 to obtain an electrospinning solution.

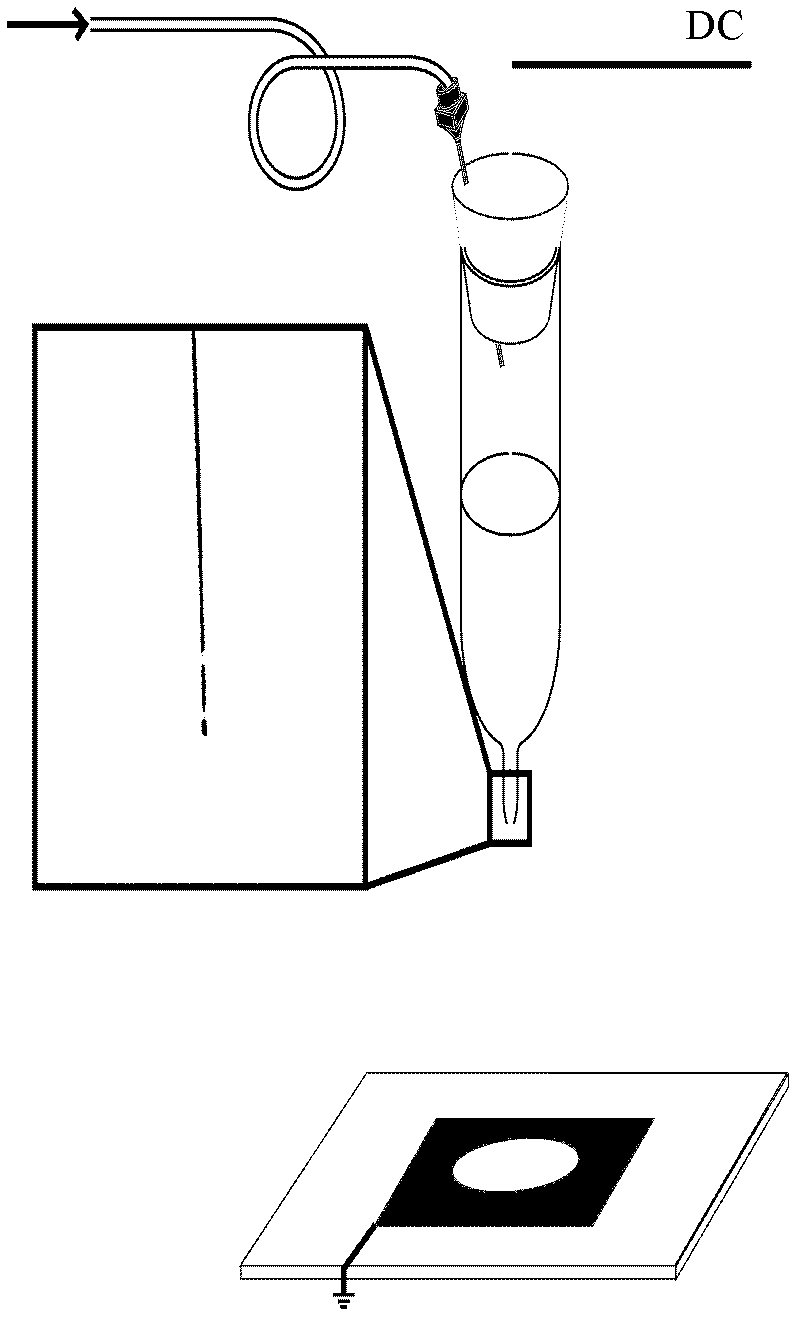

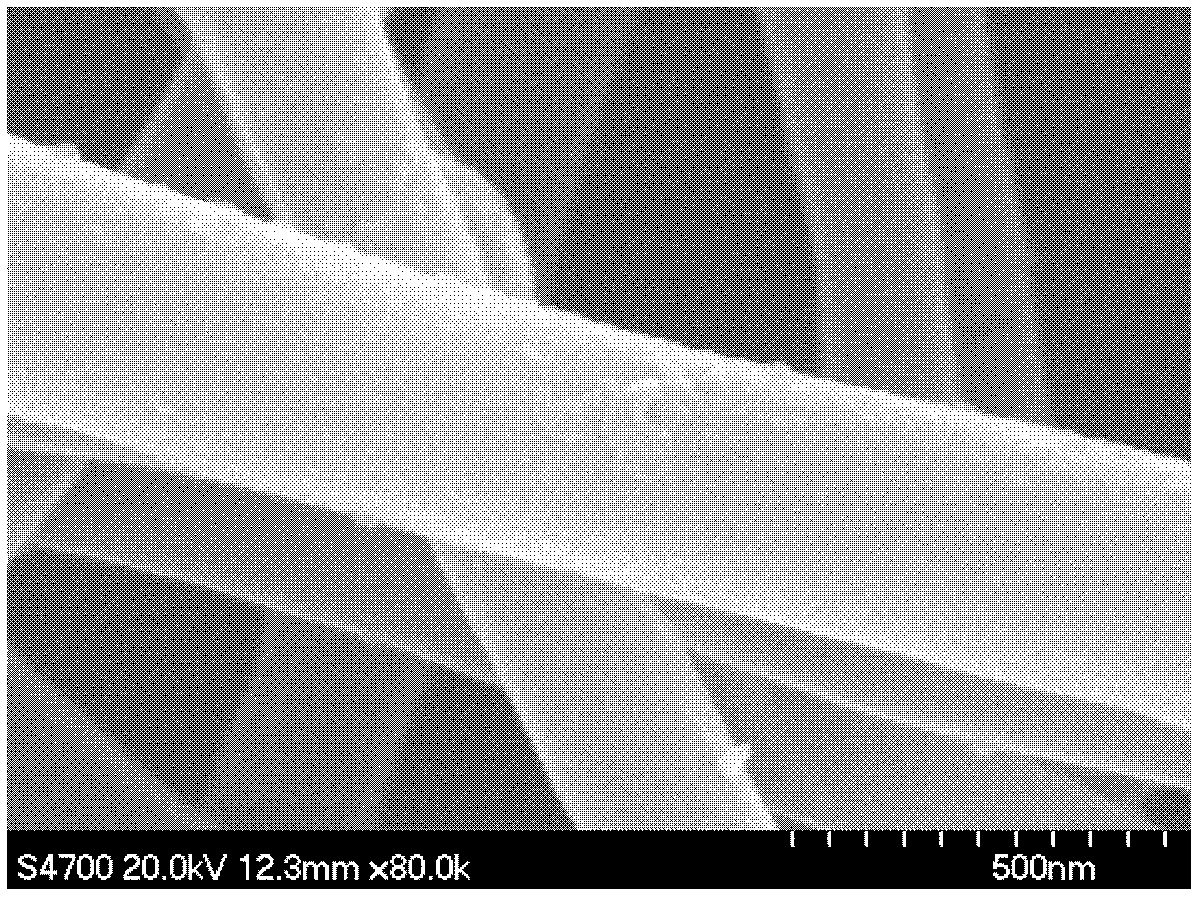

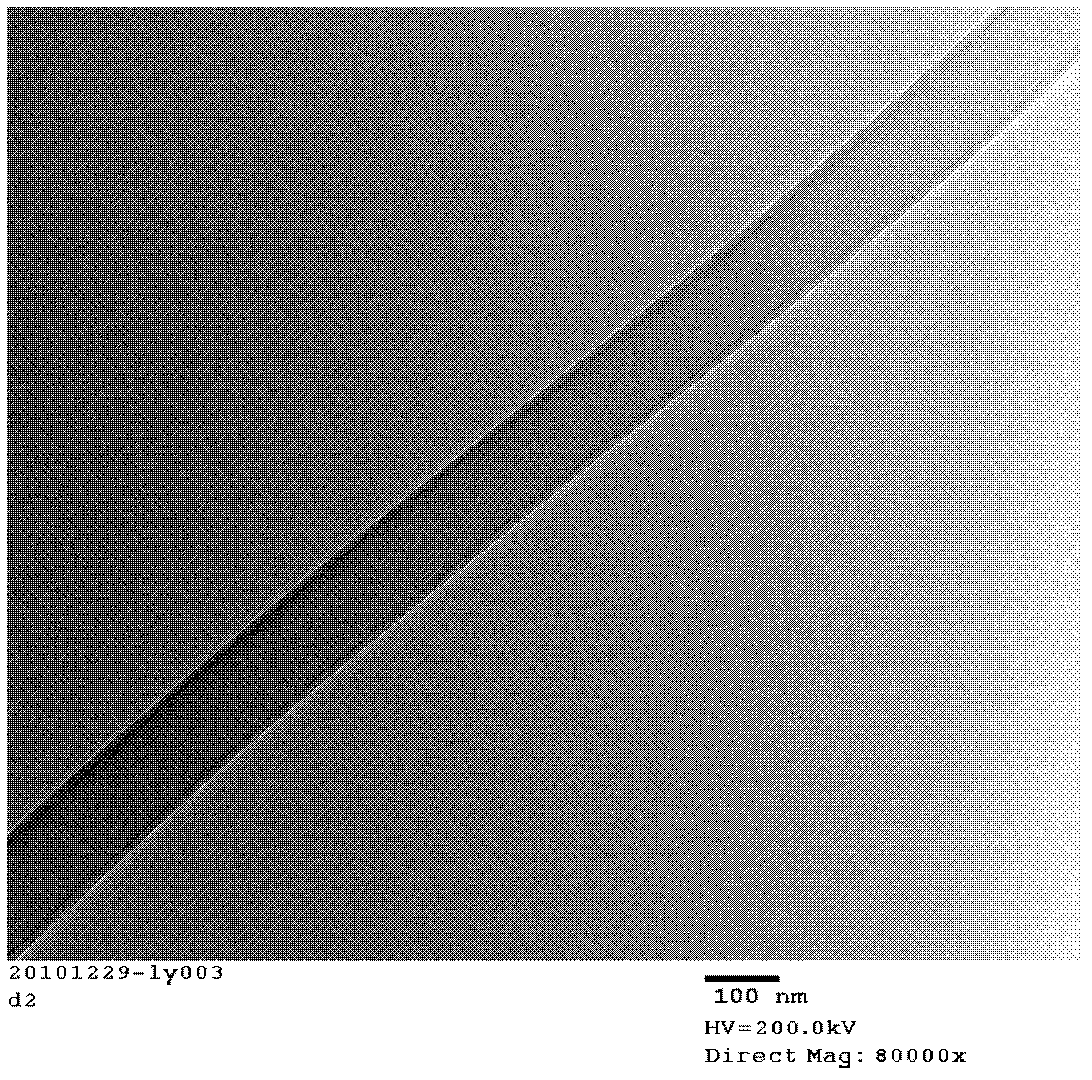

[0025] (3) Add the electrospinning solution prepared in step (2) into the solution supply device, adjust the voltage to 30kV; the distance from the spinneret to the collecting plate is 20cm; the flow rate of the spinneret spinning solution is 1mL / h. Start the device for electrospinning, and obtain hyaluronic acid / polyoxyethylene core-shell structure nanofibers on the collecting plate, w...

Embodiment 2

[0027] (5) The hyaluronic acid / polyoxyethylene core-shell structure nanofibrous membrane obtained in step (3) was subjected to a cell inoculation experiment, and it had excellent cell attachment and proliferation characteristics. Embodiment 2: (1) dissolving chitosan with a molecular weight of 3000g / mol in water is prepared into a solution of 5wt% by weight, and then the solution is fully stirred so that it is completely dissolved to obtain a chitosan solution.

[0028] (2) Dissolving polyvinyl alcohol in water to prepare a solution with a weight percentage of 10 wt%, and then fully stirring the solution so that it is completely dissolved to obtain a polyvinyl alcohol solution. The chitosan solution and the polyvinyl alcohol solution are mixed at a volume ratio of 5:1 to obtain an electrospinning solution.

[0029] (3) Add the electrospinning solution prepared in step (2) into the solution supply device, adjust the voltage to 25kV; the distance from the spinneret to the collec...

Embodiment 3

[0032] Example 3: (1) Dissolve hyaluronic acid with a molecular weight of 2 000 000 g / mol in water to prepare a solution with a weight percentage of 1 wt%, and then stir the solution fully so that it is completely dissolved to obtain a hyaluronic acid solution.

[0033] (2) Dissolving polyvinylpyrrolidone in water to prepare a solution with a weight percentage of 10wt%, and then fully stirring the solution so that it is completely dissolved to obtain a polyvinylpyrrolidone solution. The hyaluronic acid solution and the polyvinylpyrrolidone solution are mixed at a volume ratio of 9:1 to obtain an electrospinning solution.

[0034] (3) Add the electrospinning solution prepared in step (2) into the solution supply device, adjust the voltage to be -30kV; the distance from the spinneret to the collecting plate is 8cm; the flow rate of the spinneret spinning solution is 0.5mL / h. Start the device for electrospinning, and obtain hyaluronic acid / polyvinylpyrrolidone core-shell struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com