Cell sheet for tissue repair and bio-artificial tissue engineering, method of producing the same and method of using the same

A cell sheet and cell technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, biochemical instruments, etc., can solve problems such as long degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

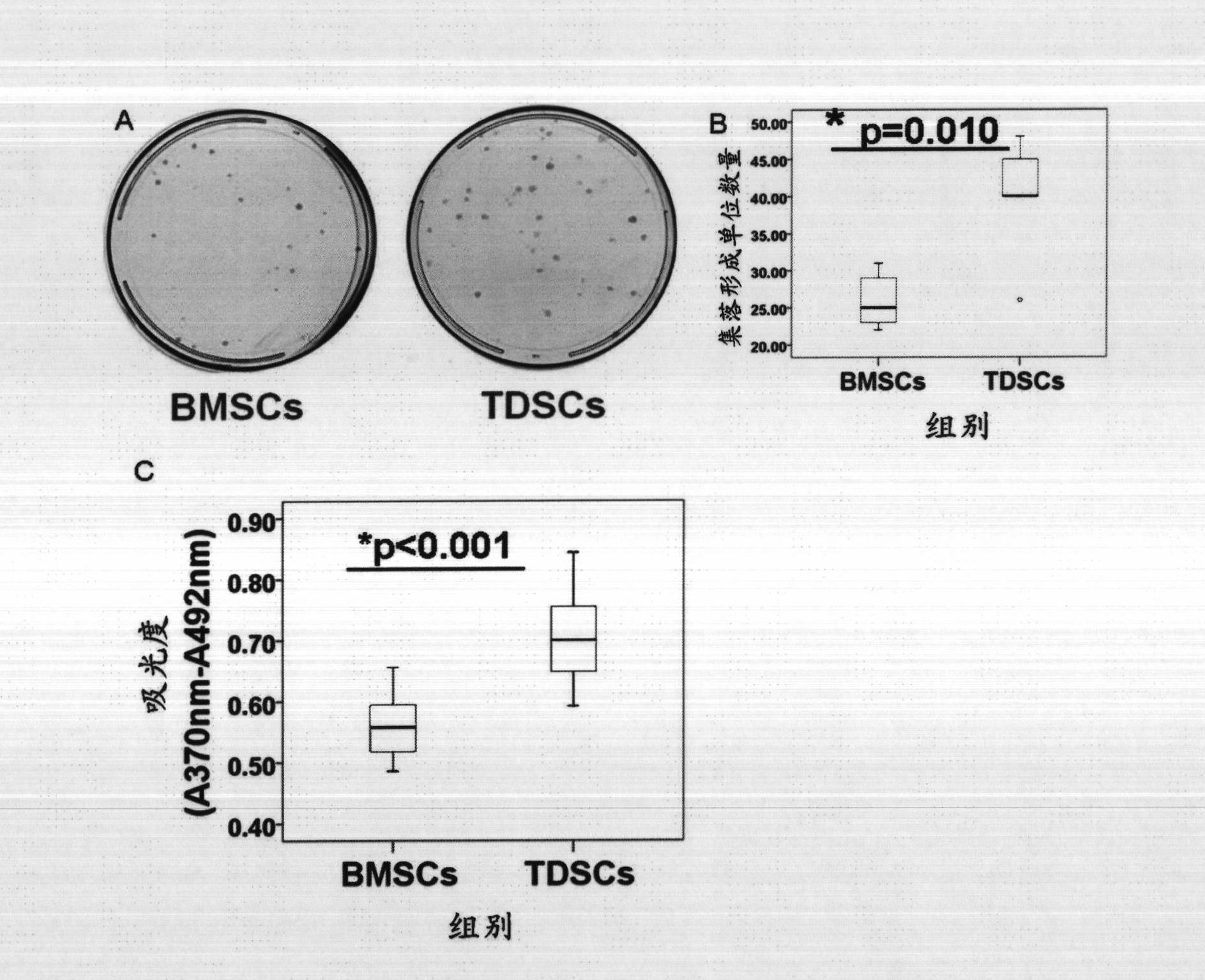

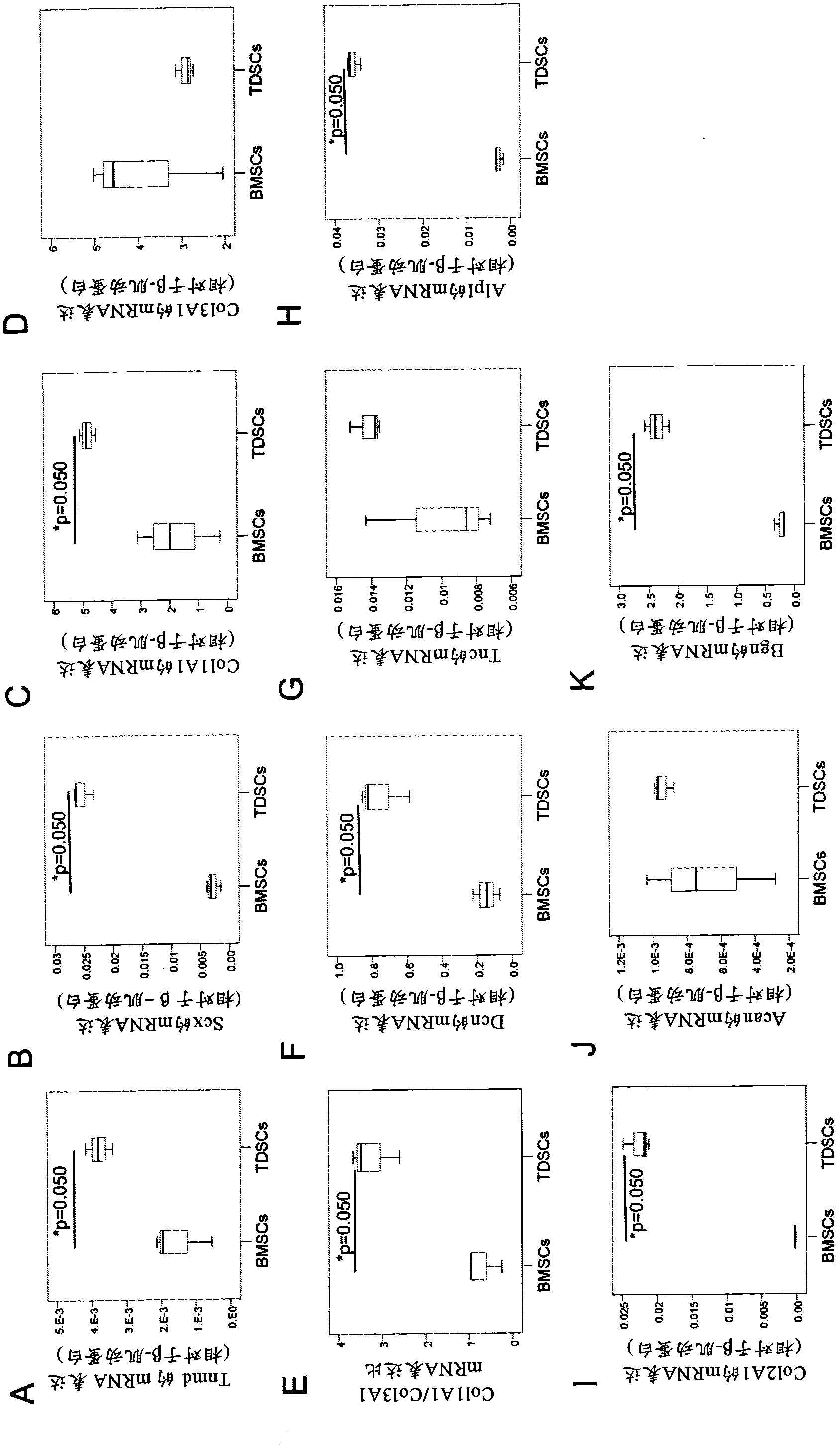

[0092] Example 1. Preparation of Cell Sheets

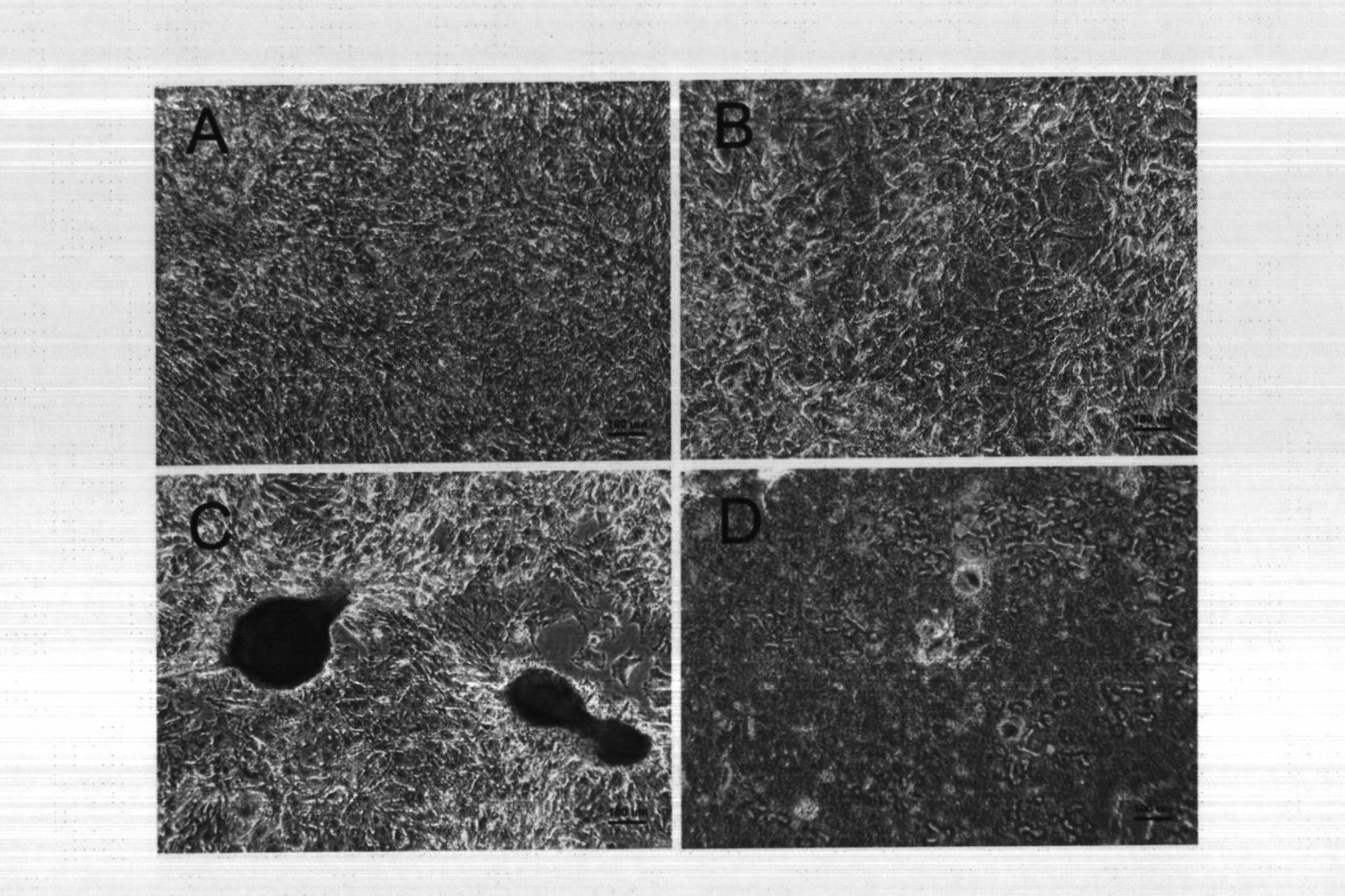

[0093] Rat TDSC stem cells were isolated from rat tendons as described by Rui et al. Tissue Eng Part A 2010; 16(5): 1549-1558. Freeze isolated TDSCs in liquid nitrogen until use. To form cell sheets, TDSC were expanded in growth medium in plastic dishes until confluent. Then, in a humidified cell culture incubator at 10-45 °C, 3-10% CO 2 Under the condition of 1- At 6 weeks, the medium also contained 2-30% fetal bovine serum (FBS), 10-500 U / ml penicillin, 10-500 μg / ml streptomycin and 1-10 mM L-glutamine. The medium containing CTGF and ascorbic acid was replaced every 2-5 days. refer to Figure 7 with Figure 12 , in a humidified incubator at 37 °C, 5% CO 2 Under the condition of , after treating stem cells with ascorbic acid (25μM) and CTGF (25ng / ml) prepared in DMEM containing 2% FBS, the treated cells differentiated, produced abundant extracellular matrix and the resulting cell sheet was elastic. The medium containing ...

Embodiment 2

[0098] Example 2. Formation of bioartificial tendons and ligaments

[0099] refer to Figure 9 , the cell sheets formed with rat TDSC were rolled up and loaded onto U-shaped elastic needles to form bioartificial tendons and ligaments. Referring to FIG. 15, after the cell sheet formed of rat TDSC was transplanted and sutured to the spinal muscle, the cell sheet was further matured. At week 8 after transplantation, cellularity was lower than at week 6, and tendon-like and ligament-like tissues were formed. The transplanted cells were viable, spindle-shaped, aligned longitudinally along the loading axis and embedded between parallel fibrils. At week 8, fibrils were thicker than before transplantation and exhibited collagen birefringence typical of tendons and ligaments.

Embodiment 3

[0100] Example 3. Tissue Repair

[0101] After removal of the patellar-patellar tendon-bone graft in anterior cruciate ligament (ACL) reconstruction, a window-like injury in the patellar tendon can be created by rolling and suturing a cell sheet with active TDSC in the window-like defect. Cell sheets are used to enhance the repair of window-like injuries in the patellar tendon. refer to Figure 16-19 , Suturing cell sheets formed with treated rat TDSC to patellar window defects promoted tendon healing. At week 2, some cells in the defect transplanted with cell sheets became flattened. This phenomenon was not observed in the group without cell sheets. In the group transplanted with cell sheets, more ECMs were observed. The ECM is aligned longitudinally along the tendon and exhibits collagen birefringence typical of ligaments and tendons. At week 2, the transplanted cell sheet was still present in the window-like defect, as shown by ex vivo fluorescence imaging. At week 8,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com