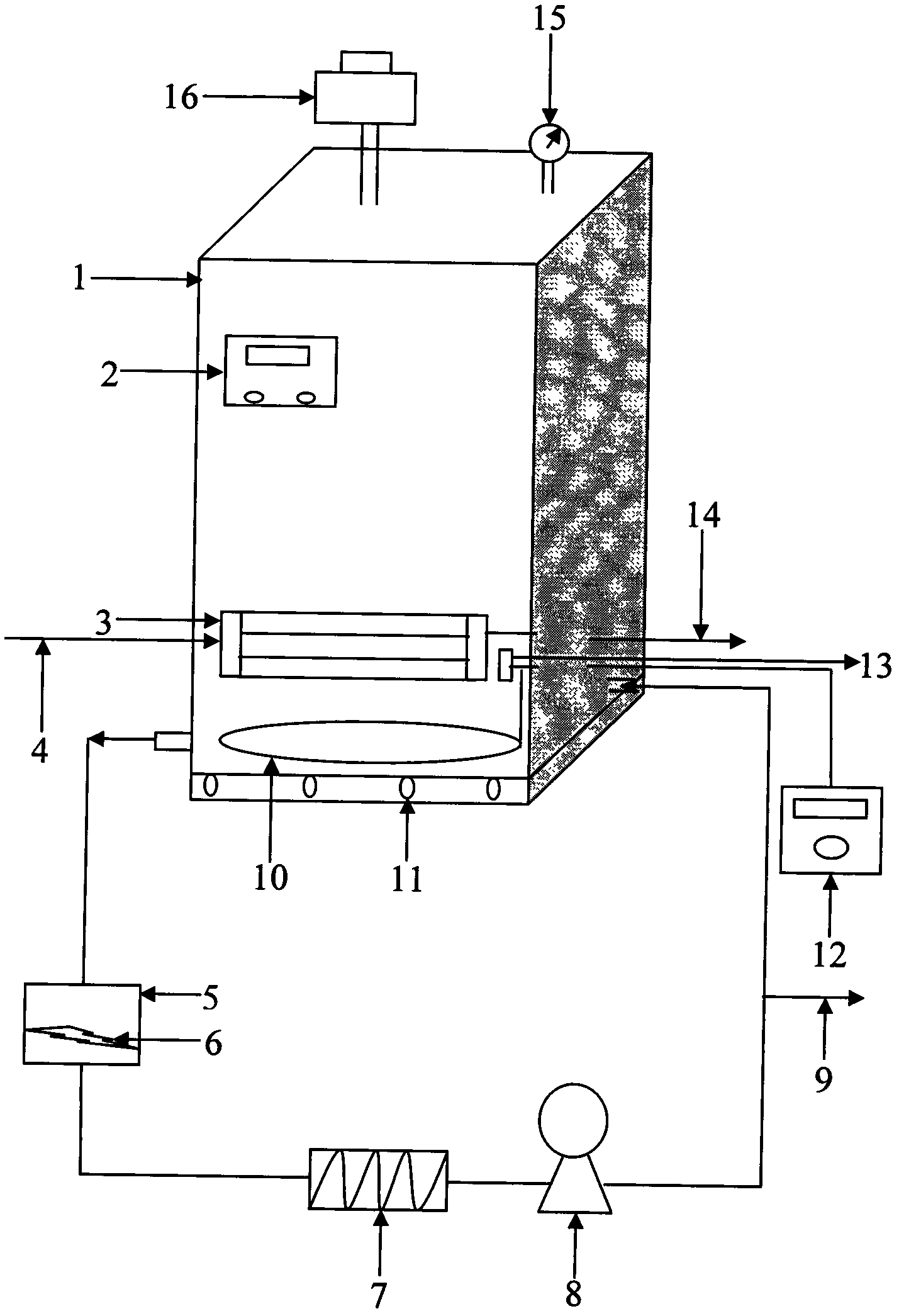

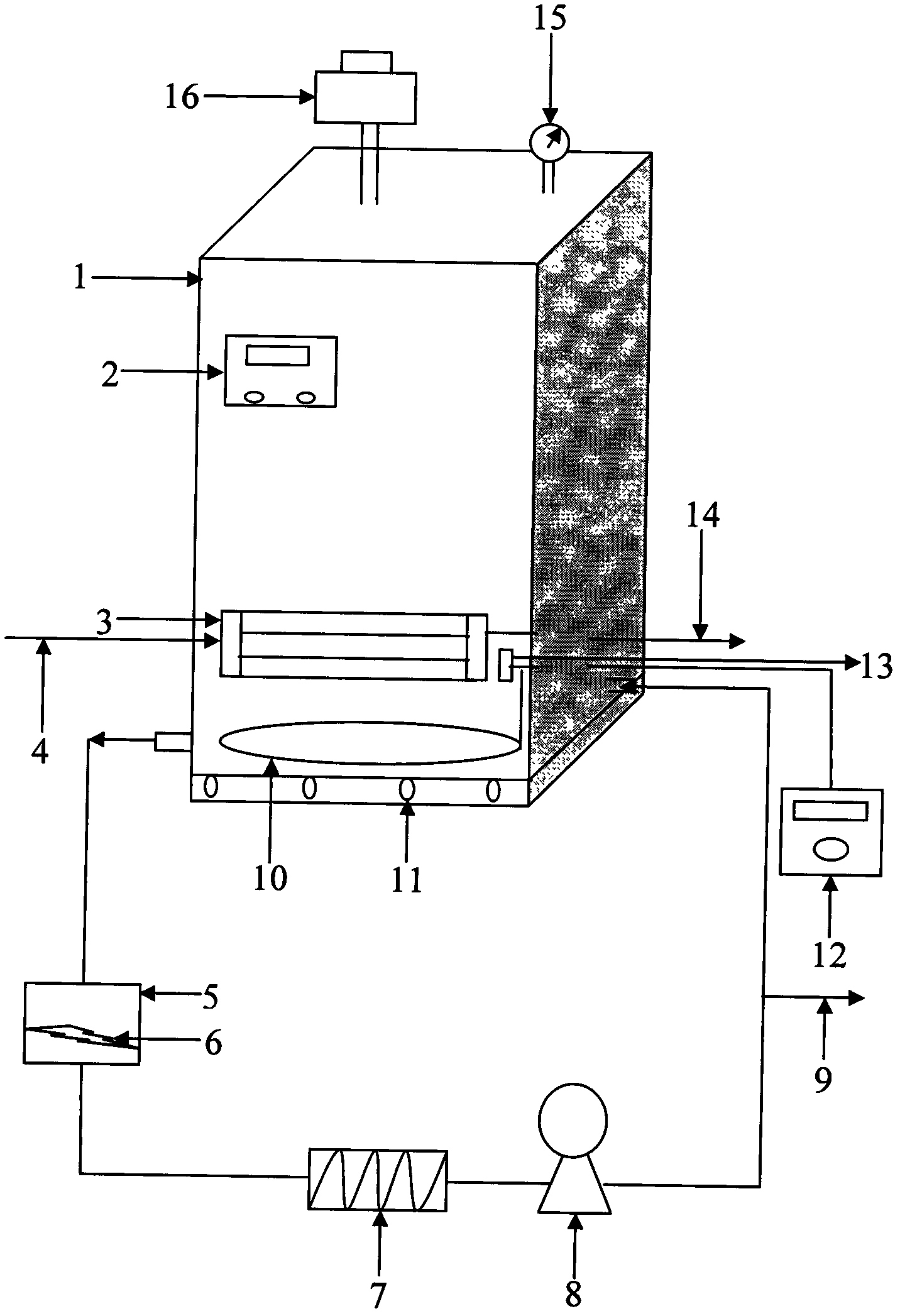

Ultrasonic reinforced membrane reactor for absorbing and gathering CO2 in flue gas

An ultrasonic and enhanced membrane technology, applied in the field of membrane separation, can solve the problems of complex flue gas purification system, low removal rate, and difficult packaging, so as to avoid absorption liquid dead zone and channeling phenomenon, increase gas-liquid contact area, and avoid Effects of different processing volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Ultrasound refers to sound waves with a frequency of 20kHz to 10MHz, which can propagate in gas, liquid or solid. When the ultrasonic wave propagates in the liquid, the interaction between the ultrasonic wave and the liquid mainly depends on the cavitation effect generated by the ultrasonic wave. The so-called ultrasonic cavitation phenomenon refers to a series of processes in which tiny cavitation bubbles (vacuum bubbles or bubbles containing gas and steam) in a liquid oscillate, grow, shrink and collapse under the action of sound waves.

[0013] In the present invention, ultrasonic technology is applied to capture CO in flue gas by membrane absorption method. 2 in the technical field. Ultrasonic Enhanced Membrane Absorption and Capture of CO in Flue Gas 2 The mechanical effects such as micro-jet and shock wave accompanied by ultrasonic cavitation can not only cause macroscopic turbulence of liquid flow and high-speed collision of solid particles, strengthen eddy cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com