Polyvinylidene fluoride-carbon nano tube composite separation film and preparation method thereof

A carbon nanotube composite and polyvinylidene fluoride technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc. Poor combination and other problems, to achieve the effect of improving pollution resistance, pure water flux, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

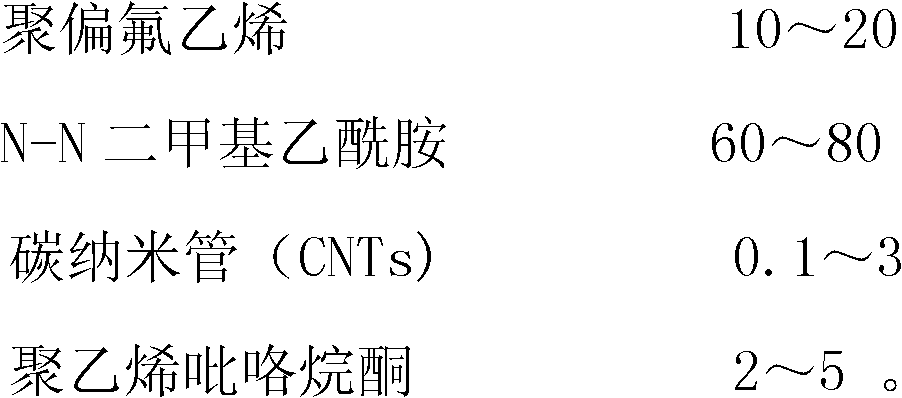

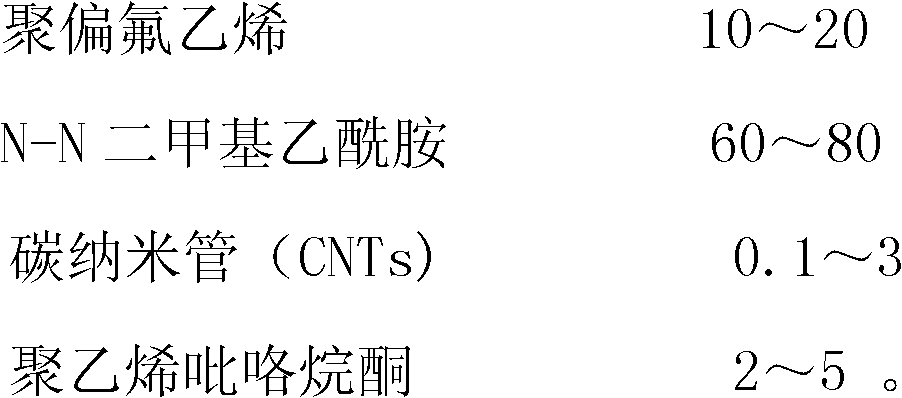

Embodiment 1

[0021] 0.2 g of multi-walled carbon nanotubes (average aspect ratio of 100:1, surface oxygen content of 6%) were ultrasonically dispersed in 70 g of N-N dimethylacetamide for 2.5 h, and then 18 g of polyvinylidene fluoride and 3g of polyvinylpyrrolidone, then mechanically stirred for 24 hours, left to stand for degassing at room temperature for 24 hours, scraped the film on a clean glass plate with a scraper, pre-evaporated the film for 30 seconds, then immersed it in deionized water until it solidified, and then rinsed it repeatedly with deionized water It is cleaned to remove solvent and porogen, and then polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane can be made.

[0022] Soak the above-mentioned polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane in deionized water for 3 to 4 days, then perform performance test after vacuum drying, and compare with pure polyvinylidene fluoride membrane. The test structure shows th...

Embodiment 2

[0023] Example 2: 0.1g of multi-walled carbon nanotubes (average aspect ratio of 500:1, surface oxygen content of 4%) was placed in 60g of N-N dimethylacetamide for ultrasonic dispersion for 2h, and then 15g of polybias was added Vinyl fluoride and 2g polyvinylpyrrolidone, then mechanically stirred for 24 hours, left to stand for degassing at room temperature for 24 hours, scraped the film on a clean glass plate with a scraper, pre-evaporated the film for 30 seconds, then immersed it in deionized water until it solidified, and then used it repeatedly After rinsing with ion water to remove solvent and porogen, the polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane can be prepared.

[0024] Soak the above-mentioned polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane in deionized water for 3 to 4 days, then perform performance test after vacuum drying, and compare with pure polyvinylidene fluoride membrane. The test structur...

Embodiment 3

[0026] 0.4g of multi-walled carbon nanotubes (with an average aspect ratio of 200:1 and a surface oxygen content of 5%) were ultrasonically dispersed in 80g of N-N dimethylacetamide for 3h, and then 20g of polyvinylidene fluoride and 3g of Polyvinylpyrrolidone, followed by mechanical stirring for 24 hours, standing at room temperature for 24 hours to defoam, use a scraper to scrape the film on a clean glass plate, pre-evaporate the film for 30 seconds, immerse it in deionized water until it solidifies, and then rinse it with deionized water repeatedly The polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane can be prepared by removing the solvent and the porogen.

[0027] Soak the above-mentioned polyvinylidene fluoride-carbon nanotube composite flat microfiltration membrane in deionized water for 3 to 4 days, then perform performance test after vacuum drying, and compare with pure polyvinylidene fluoride membrane. The test structure shows that pure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com