Preparation method for polyether sulfone/graphene oxide composite ultrafiltration membrane

A graphene composite and polyethersulfone technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of polyethersulfone ultrafiltration membranes, such as easy to be polluted mechanical properties, to improve mechanical strength, The effect of enhanced permeation flux and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

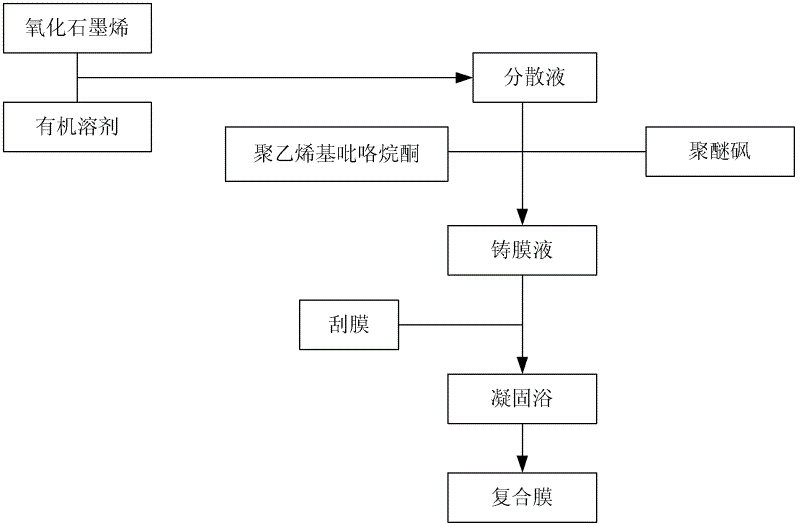

Method used

Image

Examples

Embodiment 1

[0033] Add 0.5g of graphene oxide to 79.5g of dimethylacetamide and ultrasonically disperse for 1h to form a uniform and stable dispersion, then add 18g of polyethersulfone and 2g of polyvinylpyrrolidone to the dispersion. Stir in the bath for 4 hours, then put the solution into a blast drying oven at 60°C and let it stand for 4 hours to defoam to obtain a uniformly mixed casting solution. Pour the casting solution on a glass plate, scrape the membrane with a glass rod with copper wires at both ends, and then immerse it in a coagulation bath of distilled water at room temperature. After the membrane falls off automatically, a polyethersulfone / graphene oxide composite ultrafiltration membrane.

[0034] After testing, the flux recovery rate of the obtained polyethersulfone / graphene oxide composite ultrafiltration membrane is 90%, and the BSA rejection rate remains above 95%.

Embodiment 2

[0036] Add 1.0g of graphene oxide to 79g of dimethylacetamide and ultrasonically disperse for 1h to form a uniform and stable dispersion, then add 18g of polyethersulfone and 2g of polyvinylpyrrolidone to the dispersion, and place in an oil bath at 60°C Stir for 4 hours, and then put the solution into a blast drying oven at 60°C and let it stand for 4 hours to defoam to obtain a uniformly mixed casting solution. Pour the casting solution on a glass plate, scrape the membrane with a glass rod with copper wires at both ends, and then immerse it in a coagulation bath of distilled water at room temperature. After the membrane falls off automatically, a polyethersulfone / graphene oxide composite ultrafiltration membrane.

[0037] After testing, the flux recovery rate of the obtained polyethersulfone / graphene oxide composite ultrafiltration membrane is 94%, and the BSA rejection rate remains above 95%.

Embodiment 3

[0039] Add 2g of graphene oxide to 78g of dimethylacetamide and ultrasonically disperse for 1 hour to form a uniform and stable dispersion, then add 18g of polyethersulfone and 2g of polyvinylpyrrolidone to the dispersion, and place in an oil bath at 60°C Stir for 4 hours, then put the solution into a blast drying oven at 60°C and let it stand still for 4 hours of defoaming to obtain a uniformly mixed casting solution. Pour the casting solution on a glass plate, scrape the membrane with a glass rod with copper wires at both ends, and then immerse it in a coagulation bath of distilled water at room temperature. After the membrane falls off automatically, a polyethersulfone / graphene oxide composite ultrafiltration membrane.

[0040] After testing, the flux recovery rate of the obtained polyethersulfone / graphene oxide composite ultrafiltration membrane is 94.5%, and the BSA rejection rate remains above 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com