Rotating liquid film reactor and application thereon in terms of preparation of layered double hydroxides

A liquid film reactor and layered composite technology, which is applied in the direction of oxide/hydroxide preparation, etc., can solve the influence of synthetic hydrotalcite particle size and uniform dispersion performance, concentration gradient, slow reaction speed and diffusion speed, and limited layer In order to achieve the effect of increasing the efficiency of collision reaction, narrow grain size distribution and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

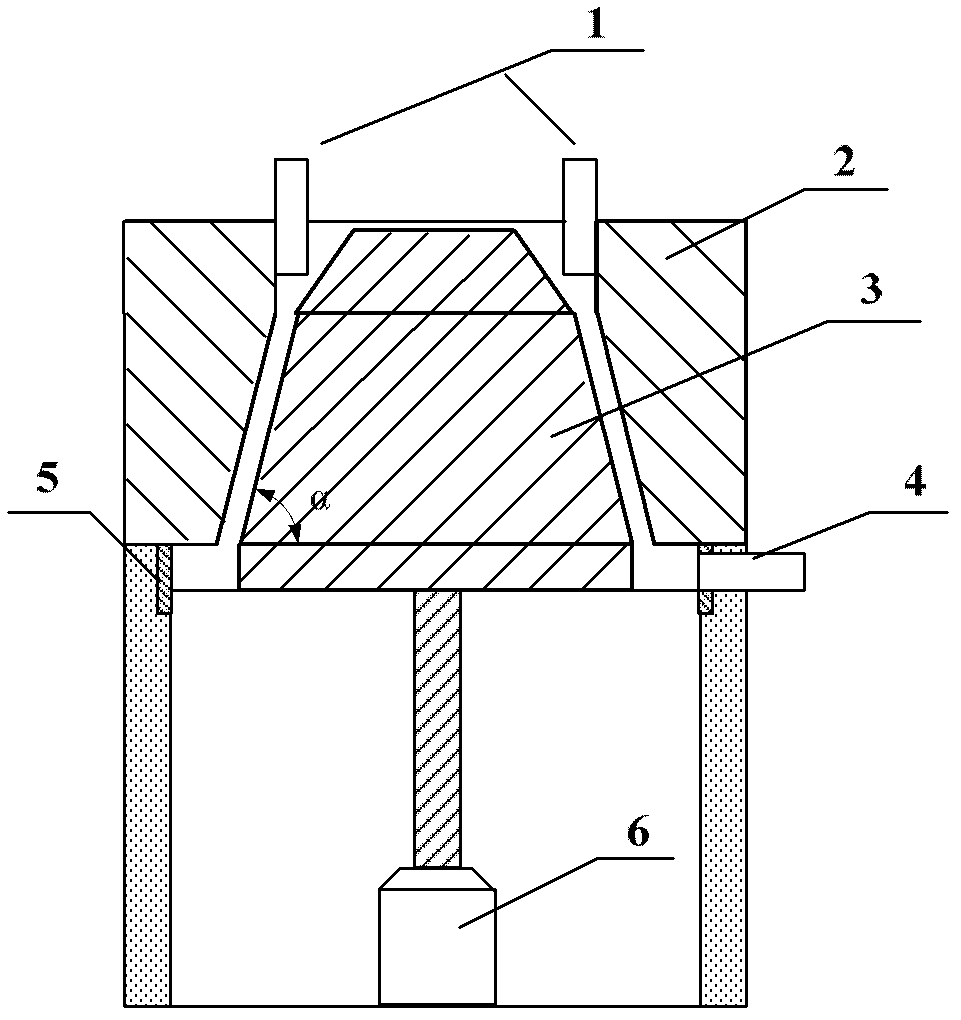

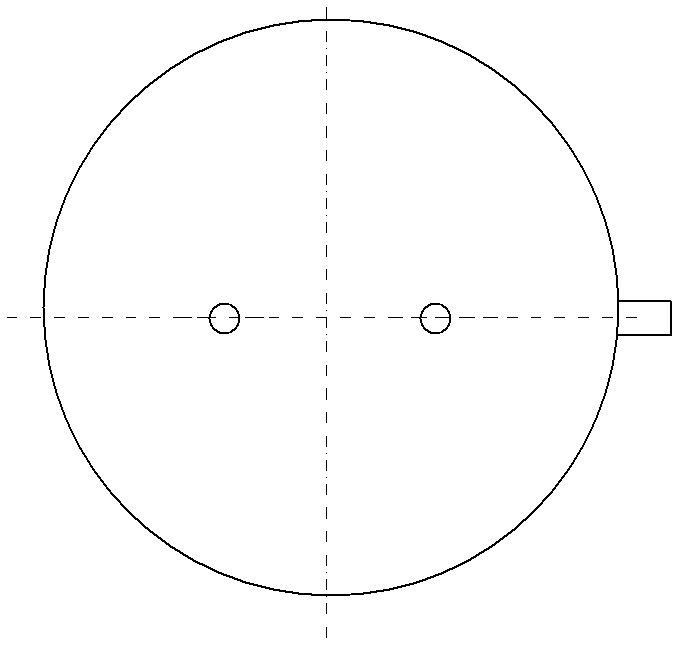

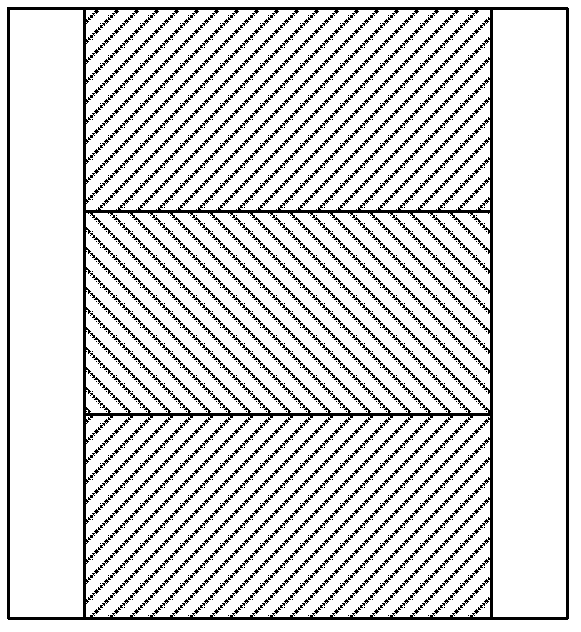

[0030] Such as figure 1 The rotating liquid film reactor shown has a closed casing as the stator, and the upper end of the stator is closed; there is a rotatable conical rotor inside the stator, and the motor is connected to the bottom of the rotor; the rotor consists of an upper cone, a middle cone and a bottom cylinder. Composed of three parts, these three parts are composed of three separate parts; the cone angle of the upper cone is 45 degrees, the height is 6cm, the distance between the top surface and the upper casing of the stator is 1.5cm, and the bottom surface is connected with the middle cone ; The cone angle of the middle cone is 65 degrees, the height is 9cm, its top surface is connected with the upper cone, and the cross-sectional area of the joint is the same, and its bottom surface is connected with the bottom cylinder; the bottom cylinder section is connected with the middle cone The size of the bottom surface is the same, the diameter is 10cm, and the heigh...

Embodiment 2

[0037] Such as figure 1 The rotating liquid film reactor shown has a closed casing as the stator, and the upper end of the stator is closed; there is a rotatable conical rotor inside the stator, and the motor is connected to the bottom of the rotor; the rotor consists of an upper cone, a middle cone and a bottom cylinder. Composed of three parts, these three parts are combined by three separate parts or processed as a whole; the cone angle of the upper vertebral body is 55 degrees, the height is 8cm, the distance between the top surface and the upper shell of the stator is 2cm, and the bottom surface and the middle part The cones are connected; the cone angle of the middle cone is 75 degrees, and the height is 10cm. The same size as the bottom surface of the middle cone, with a diameter of 50cm and a height of 5cm; two feed ports are symmetrically arranged between the upper cone of the rotor and the stator, and the feed ports are lower than the upper edge of the upper cone of ...

Embodiment 3

[0043] Adopt the rotating liquid film reactor of embodiment 1 to prepare layered composite metal hydroxide, its specific steps are:

[0044] Mg(NO 3 ) 2 , Zn(NO 3 ) 2 and Al(NO 3 ) 3 by Mg 2+ / Zn 2+ / Al 3+ =3:1:2 molar ratio is made into mixed salt solution, wherein [Mg 2+ +Zn 2+ ]=1.4mol / L; NaOH and Na 2 CO 3 Dissolve in deionized water to form a mixed alkali solution of the same volume, where n(NaOH) / [n(Mg 2+ )+n(Al 3+ )]=2.4, n(Na 2 CO 3 ) / n(Mg 2+)=1.6; The two solutions are added to the reactor through two feeding ports of the rotary liquid film reactor respectively at a flow rate of 8kg / min, the slit of the reactor is 30 μm, and the rotor speed is 3000rpm, and the slurry obtained by the reaction is crystallized Crystallize in a kettle at 150°C for 3 hours, filter, wash and dry to obtain a layered composite metal hydroxide, whose chemical formula is Mg 3 ZnAl 2 (OH) 12 (CO 3 )·4H 2 O. The average particle size of the product is 100nm, and the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com