Method for extracting concentrated S-adenosylmethionine

A technology of adenosylmethionine and feed liquid, which is applied in the field of biopharmaceuticals, can solve the problems of high toxicity, poor specificity, and strong irritation of trichloroacetic acid, and achieve the elimination of milk making and demulsification processes, and the separation process is simple and reliable. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

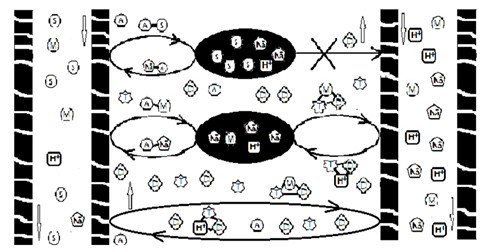

[0045] Figure 4 It is a schematic diagram of the process of extracting and concentrating SAM using synchronous analytical support liquid membrane separation technology, which is now passed Figure 4 The specific technical process of this embodiment is described.

[0046] Step 1: The biological fermentation liquid of SAM in the feed-liquid phase container 1 is the feed-liquid phase, wherein the concentration of SAM is 10 mM, the total volume of the feed-liquid phase is 800 mL, and the pH value of the feed-liquid phase is adjusted to 3.0 with phosphoric acid. Start the constant flow pump 4 to circulate the feed liquid phase through the tube side of the hollow fiber membrane module 7, the flow rate of the constant flow pump is 400mL / min, and the pressure of the pressure gauge 12 is controlled by the ball valve 10 to 9psi.

[0047] Step 2: The extractant is AOT / DEHPA / TOPO, the molar ratio is 5:30:2, n-octanol is used as the solvent, and the volume of the liquid film phase is 800...

Embodiment 2

[0053] Step 1: Use hydrochloric acid to adjust the pH value of the liquid phase of the feed to 3.5, the flow rate of the constant flow pump is 100mL / min, the pressure of the pressure gauge 12 is 5psi, and other conditions are the same as in Example 1.

[0054] Step 2: The extractant AOT / DEHPA / TOPO molar ratio is 2:10:1, with n-butanol as solvent, weak electrolyte solution is 1.0mM sodium acetate solution, acetic acid to adjust pH to 2.0, add 0.5mM sodium chloride . The flow rate of the constant flow pump is 200mL / min, the pressure of the pressure gauge 13 is 3psi, the pressure gauge 14 is about 2psi, and other conditions are the same as in Example 1.

[0055] Step 3: the weak electrolyte solution in the secondary analytical phase is 0.5 mM sodium acetate solution, the pH is adjusted to 1.0 with hydrochloric acid, and 0.5 mM sodium chloride is added. The flow rate of the constant flow pump is 100mL / min, the pressure of the pressure gauge 15 is 5psi, and other conditions are th...

Embodiment 3

[0060] Step 1: Phosphoric acid is used to adjust the pH value of the liquid phase of the material to 3.0, the flow rate of the constant flow pump is 800mL / min, the pressure of the pressure gauge 12 is 10psi, and other conditions are the same as in Example 1.

[0061] Step 2: The molar ratio of extractant AOT / DEHPA / TOPO is 6:50:3, dedecyl alcohol is used as solvent, the weak electrolyte solution is 1.0 mM sodium phosphate solution, the pH is adjusted to 2.5 with hydrochloric acid, and 3.0 mM sodium chloride is added. The flow rate of the constant flow pump is 1000mL / min, the pressure of the pressure gauge 13 is 5psi, the pressure of the pressure gauge 14 is about 4psi, and other conditions are the same as in Example 1.

[0062] Step 3: The weak electrolyte solution in the secondary analytical phase is 1.0 mM sodium phosphate solution, the pH is adjusted to 1.5 with hydrochloric acid, and 2.0 mM sodium chloride is added. The flow rate of the constant flow pump is 800mL / min, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com