Polybutadiene latex synthesis process

A polybutadiene latex and synthesis process technology, applied in the field of engineering plastics ABS production, can solve the problems of complex process, increase equipment investment and energy consumption, increase nitrogen consumption and other problems, achieve simple operation process, realize comprehensive utilization, The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

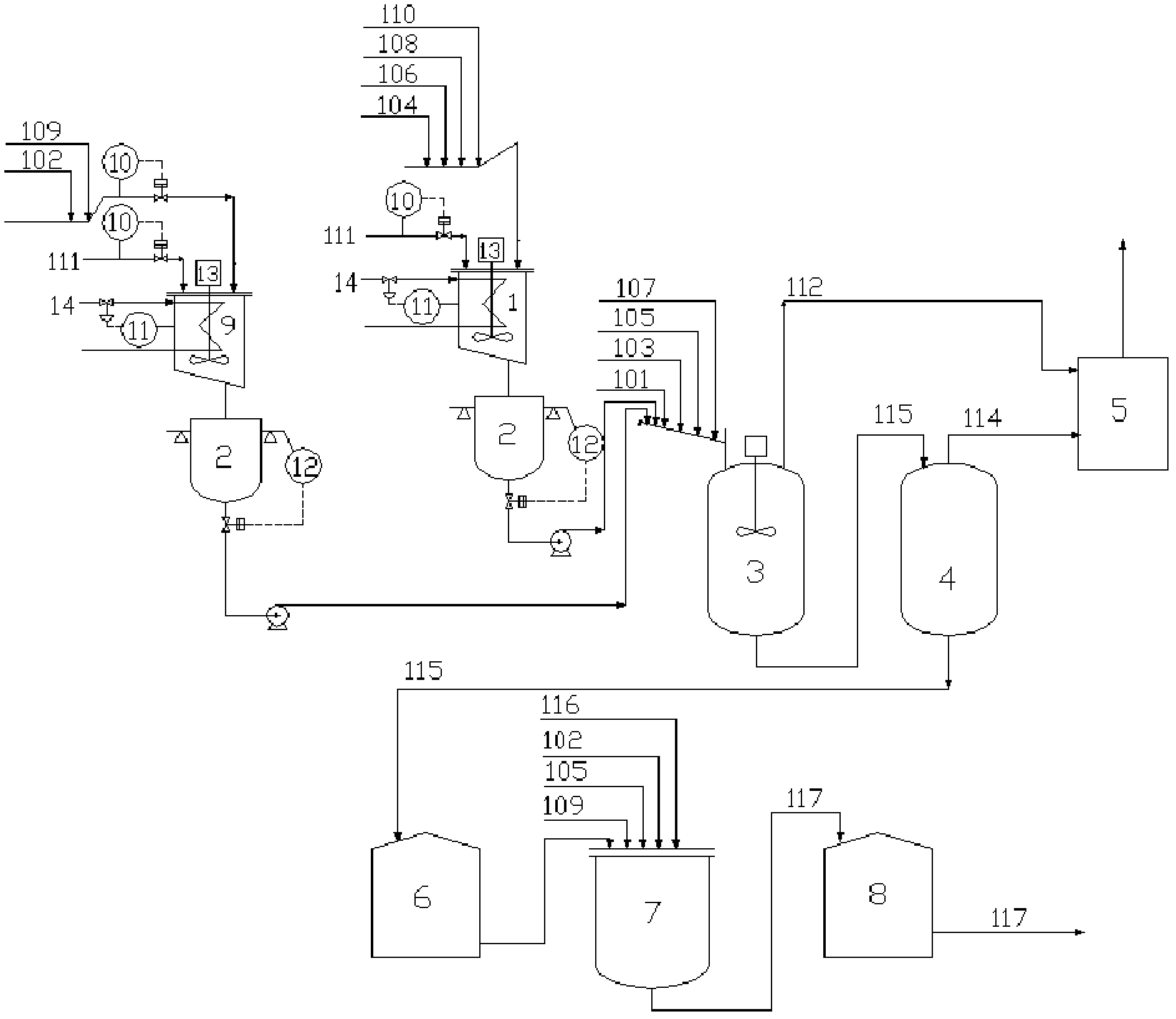

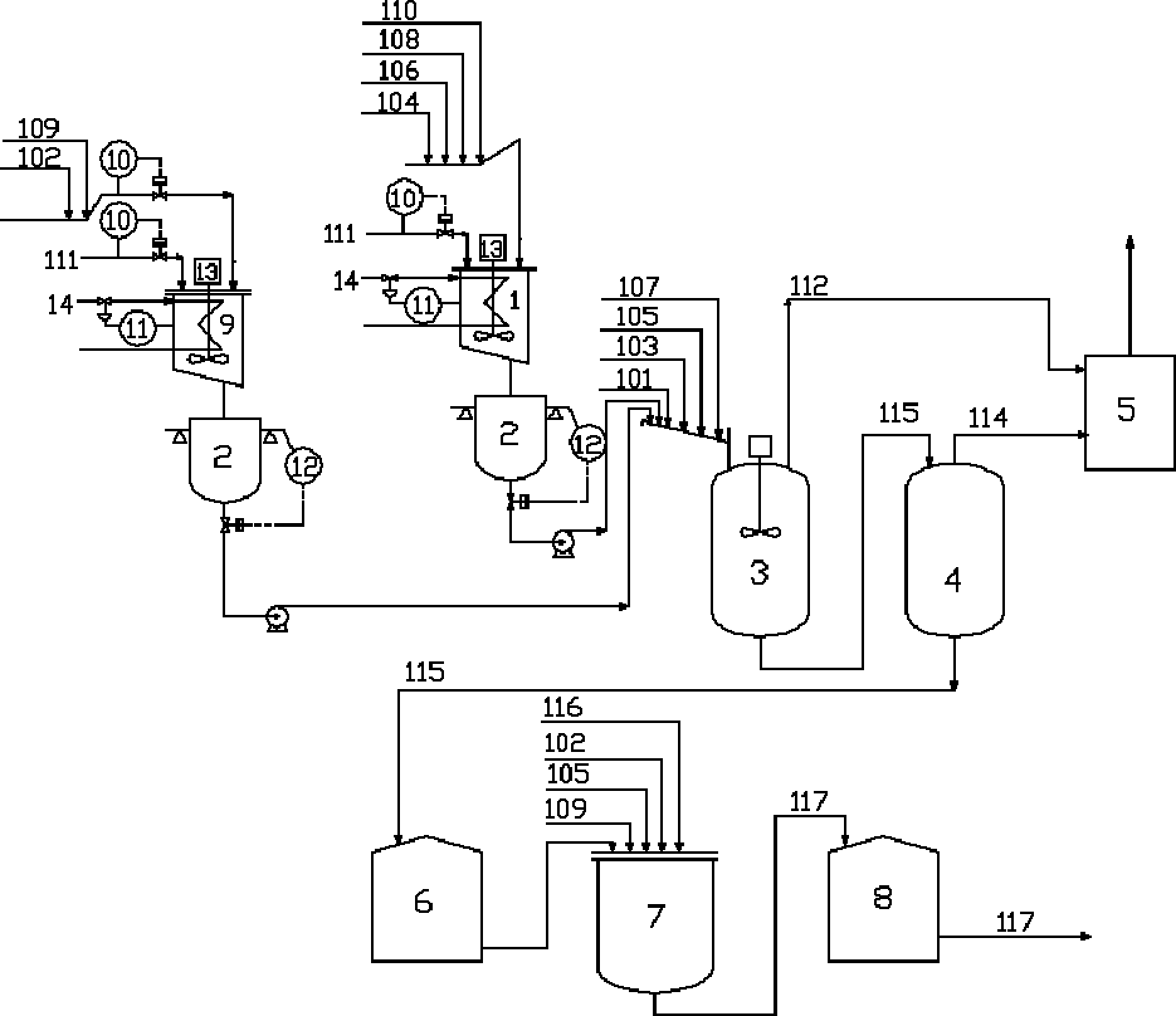

[0056] A kind of polybutadiene latex synthesis technique, comprises the steps:

[0057] (1) The liquid additive (potassium oleate 109, potassium hydroxide 102, acetic acid 116) is diluted and prepared to the required concentration by the liquid additive reagent preparation system of the present invention and then enters the metering tank 2. With the solid additive reagent preparation system of the present invention, solid additive (potassium carbonate 110, disproportionated rosin potassium soap 104, initiator 106, potassium pyrophosphate 108) is dissolved and prepared into the metering tank 2 after the concentration required for the reaction, and each additive Each has its own preparation tank and metering tank 2;

[0058] (2) Polymerization reactor 3 is evacuated to 60mmHg, then adds desalted water 105, adds potassium hydroxide 102, potassium oleate 109, disproportionated rosin potassium soap 104, potassium carbonate 110, then adds benzene Ethylene 107, tert-dodecyl mercapta...

Embodiment 2

[0064] A kind of polybutadiene latex synthesis technique, comprises the steps:

[0065] (1) The liquid additive (potassium oleate 109, potassium hydroxide 102, acetic acid 116) is diluted and prepared to the required concentration by the liquid additive reagent preparation system of the present invention and then enters the metering tank 2. With the solid additive reagent preparation system of the present invention, solid additive (potassium carbonate 110, disproportionated rosin potassium soap 104, initiator 106, potassium pyrophosphate 108) is dissolved and prepared into the metering tank 2 after the concentration required for the reaction, and each additive Each has its own preparation tank and metering tank 2;

[0066] (2) Polymerization reactor 3 is evacuated to 70mmHg, then adds desalted water 105, adds potassium hydroxide 102, potassium oleate 109, disproportionated rosin potassium soap 104, potassium carbonate 110, then adds benzene Ethylene 107, tertiary dodecyl merc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com