Preparation of environment friendly calcium-zinc composite heat stabilizer and its application in PVC (polrvinyl chloride)

A heat stabilizer and calcium-zinc composite technology, applied in the field of material science application technology development, can solve problems such as human health hazards, achieve the effects of preventing thermal decomposition, broad application prospects, and strengthening absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of epoxy calcium oleate (zinc) is as follows: in the 250ml there-necked flask that is equipped with stirrer, thermometer, constant pressure funnel, add 20g oleic acid, certain quality formic acid (88%), stirring speed is controlled at 180r / Min, heat the water bath to 60°C, add hydrogen peroxide dropwise while reacting, the speed is controlled at 5-8d / min, keep dropping within 1 hour, then react at constant temperature for 4h, let the reaction product stand and separate, and take the upper layer of oily product. Dissolve 15g NaOH in 450ml water, heat to 90°C, then slowly add the refined epoxy oleic acid product, heat and stir, adjust the pH to about 8-9, stir and react at 90°C for 1 hour to obtain epoxy oil Sodium acid. 18g CaCl 2 (or 27.5g ZnCl 2 ) was dissolved in 100g of water, slowly added to epoxy sodium oleate solution, adjusted to a pH of about 9, stirred and reacted for 1 hour at 90°C to obtain epoxy calcium oleate (zinc).

Embodiment 2

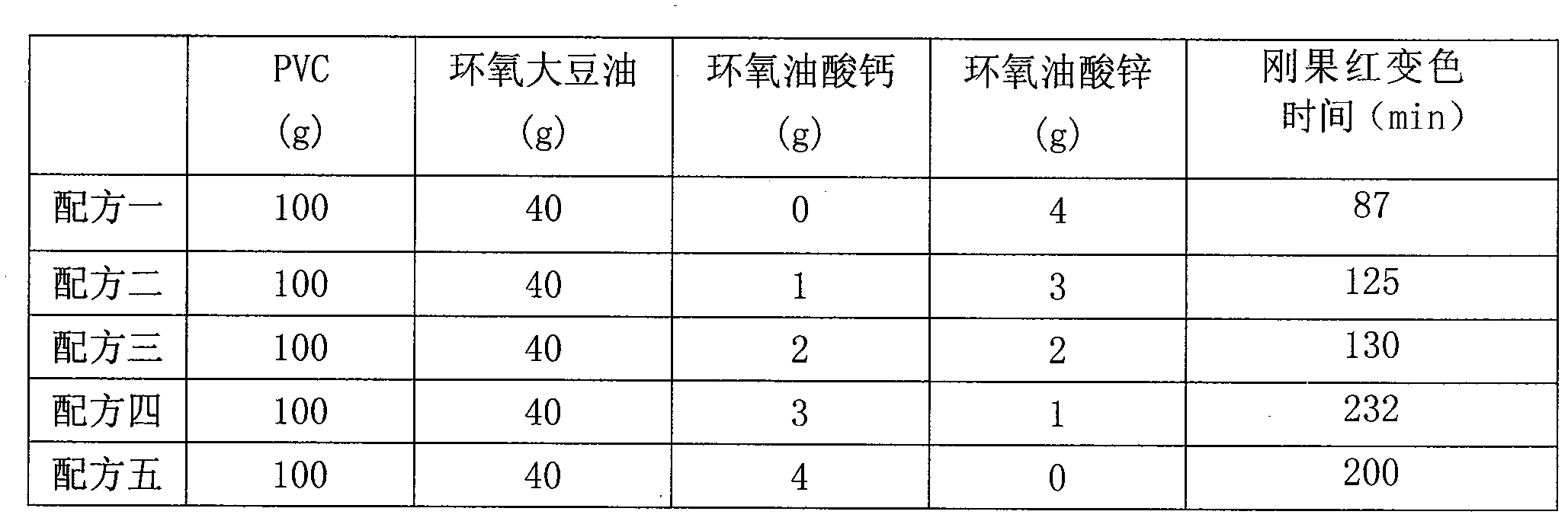

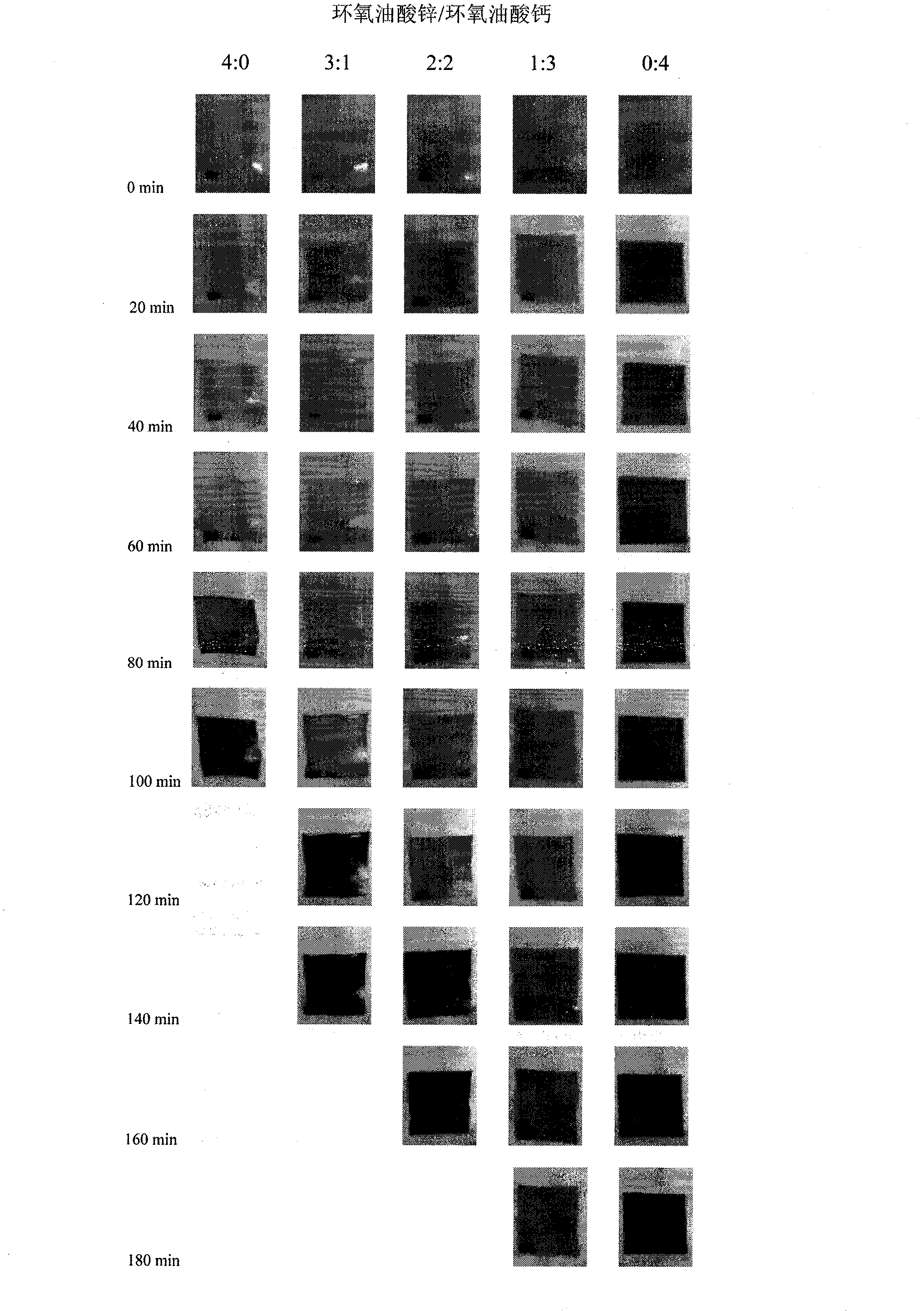

[0021] Compounding of epoxy calcium zinc oleate compound stabilizer and a certain amount of epoxy soybean oil as plasticizer

[0022] Add 40 parts of epoxy soybean oil and 4g of epoxy zinc oleate to 100 parts of PVC, and mix at high speed for 5 minutes.

Embodiment 3

[0024] Compounding of epoxy calcium zinc oleate compound stabilizer and a certain amount of epoxy soybean oil as plasticizer

[0025] Add 40g epoxy soybean oil, 3g epoxy zinc oleate, 1g epoxy calcium oleate to 100g PVC, mix at high speed for 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com