Full-biology-base composite material

A composite material and all-biological technology, which is applied in the field of all-bio-based benzoxazine copolymer resin as a substrate, can solve the problem that there is no all-bio-based benzoxazine copolymer resin, and no polymer substrate technology invention or literature report has been found. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

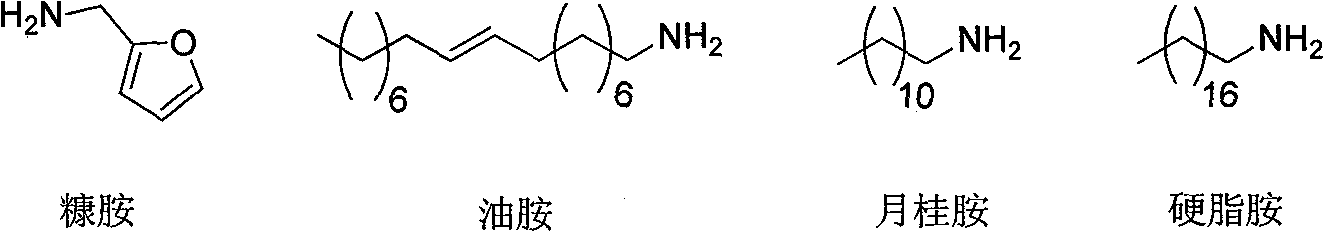

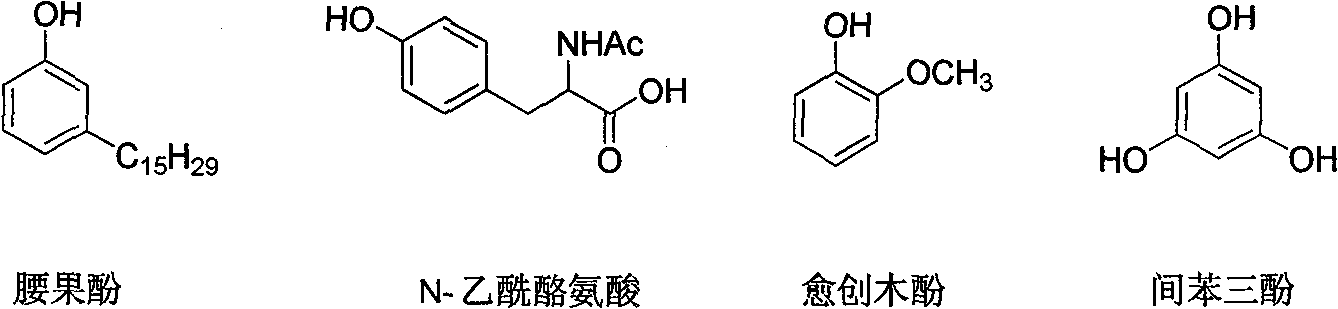

[0016] ①Synthesis of monomer 1: furfurylamine (4.40L, 50mol), paraformaldehyde (3.00kg, 100mol), stirred at room temperature until the solid dissolved, added guaiacol (6.21kg, 50mol), stirred and heated to 70°C, reacted After 1 hour, a yellow-white solid crude product was obtained, which was dissolved in absolute ethanol and purified by recrystallization. The solvent was removed by vacuum drying to obtain a white solid product (yield 92%), which was proved to be the desired benzoxazine product by detection.

[0017] ②Synthesis of monomer 2: react furfurylamine (4.40L, 50mol) with levulinic acid (2.90kg, 25mol) under acidic conditions to synthesize bisfurfurylaminovaleric acid, then add guaiacol (6.21kg, 50mol ) to obtain a white solid product (yield 91%) as described above. The product was characterized and proved to be the desired benzoxazine product.

[0018] ③Composite material preparation and performance characterization: the above two monomers were copolymerized in a rat...

Embodiment 2

[0020] ①Synthesis of monomer 1: Stearylamine (13.48kg, 50mol) was dissolved in 201 absolute ethanol, stirred for 30 minutes, formaldehyde solution (37wt%, 7.50L, 100mol), the temperature was controlled below 10°C, and stirred for 20 minutes. Add guaiacol (6.21kg, 25mol), stir for 25 minutes, raise the temperature to 70°C, and react for 6 hours to obtain a yellow viscous product, which is dissolved in absolute ethanol and purified by recrystallization, and the product obtained by vacuum drying is a light yellow solid. Yield 88%. Various characterizations of the product proved to be the desired benzoxazine product.

[0021] ②Synthesis of monomer 2: react furfurylamine (4.40Ll, 50mol) with levulinic acid (2.90kg, 25mol) under acidic conditions to synthesize difurfurylaminovaleric acid, then add cardanol (15.08kg, 50mol) to press The above method produces dark reddish-brown liquid product with a yield of 91%. The product was characterized and proved to be the desired benzoxazine...

Embodiment 3

[0024] According to embodiment 1, only change the phenol in 1. monomer synthesis into phloroglucinol (2.10kg, 16.7mol) and the product obtained is a brownish yellow solid (90% yield), and then use the same method with 2. single Composite materials were prepared from the body, and various performance tests were carried out on the samples. The results showed that the tensile modulus was 3.25GPa, the tensile strength was 43MPa, and the elongation at break was 1.61%; the flexural modulus was 3.23GPa, and the flexural strength was 128MPa; the impact strength was 3.27KJ / m 2 ; The glass transition temperature is 255°C; under the conditions of heating at 800°C and nitrogen protection, the residual carbon rate of the sample after decomposition is 52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com