Streptomyces and application thereof

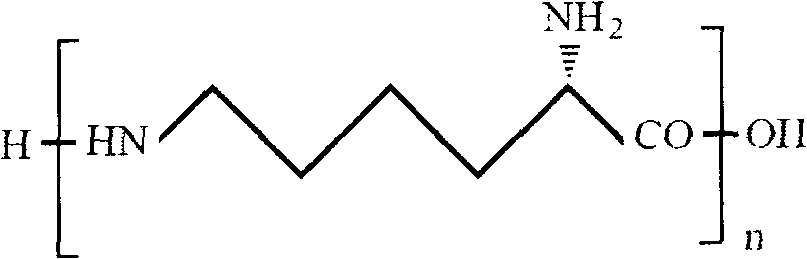

A Streptomyces, No. 1 technology, applied in the direction of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the lack of ε-polylysine synthesis ability, low production capacity and level of ε-polylysine, and unsatisfactory issues such as increasing living standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

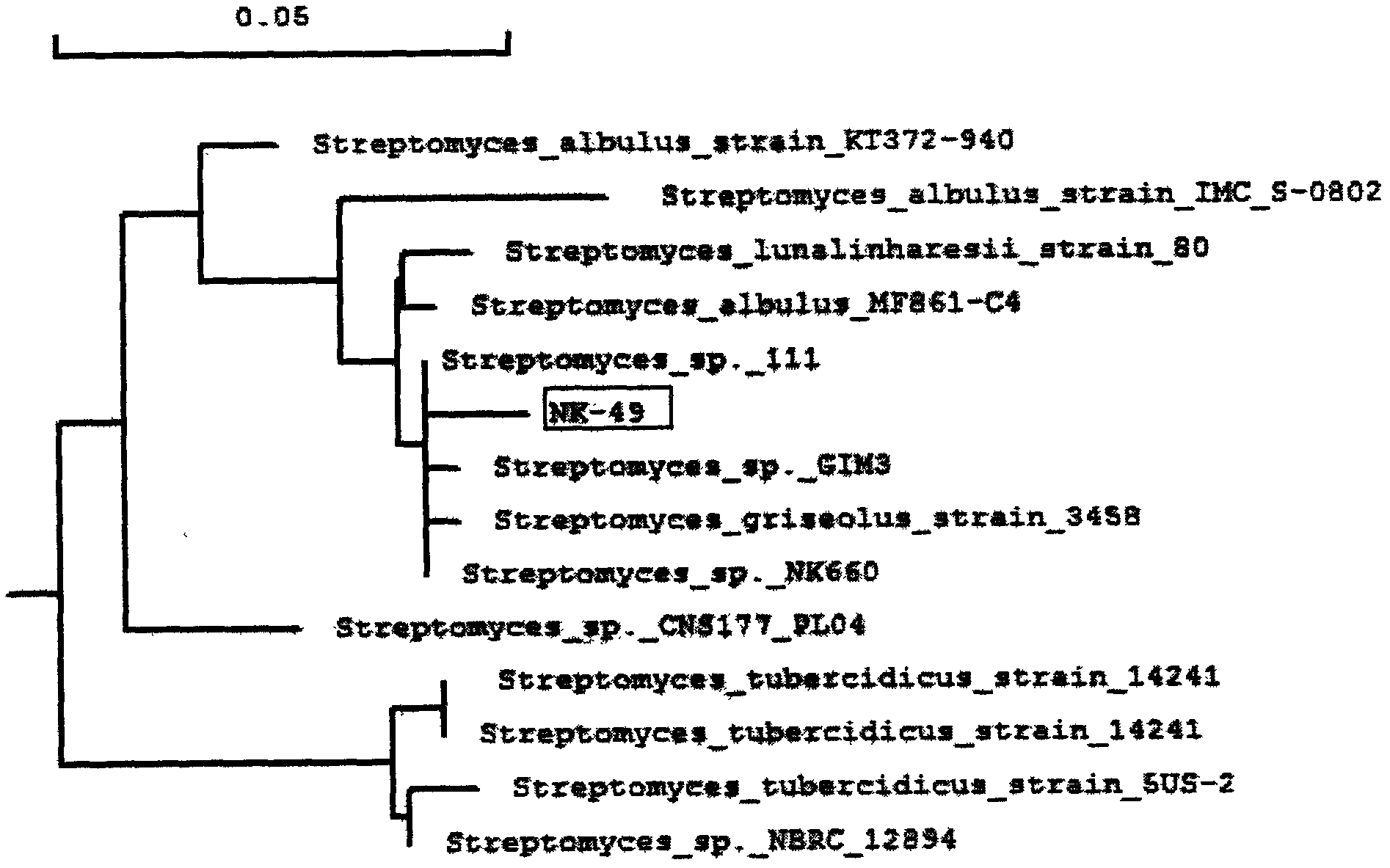

[0029] Example 1. Isolation and identification of Streptomyces sp.NK49

[0030] The experimental materials come from farmland soil in Shenyang, Liaoning Province. The specific steps are as follows:

[0031] Place the fresh soil samples taken in a cool and dry place for 3 days, then mix them evenly with 15% calcium carbonate, and then place them in a cool place to dry naturally for 8 days. Take 1g of the dried and sieved soil sample and 9ml of the diluent used to dilute the soil, oscillate and mix well, take the supernatant for gradient dilution, and apply the 100-fold and 1000-fold diluted supernatant to the solution added with 50mg / L K 2 Cr 2 o 7 The Gaoshi No. 1 medium plate was used for the isolation of ε-polylysine-producing strains; after 7 days of cultivation, the actinomycete colonies with dry and dense surface were selected, and the plate was streaked to contain no K 2 Cr 2 o 7 Purify colonies on the Gaoshi No. 1 medium plate, then pick independent colonies, inoc...

Embodiment 2

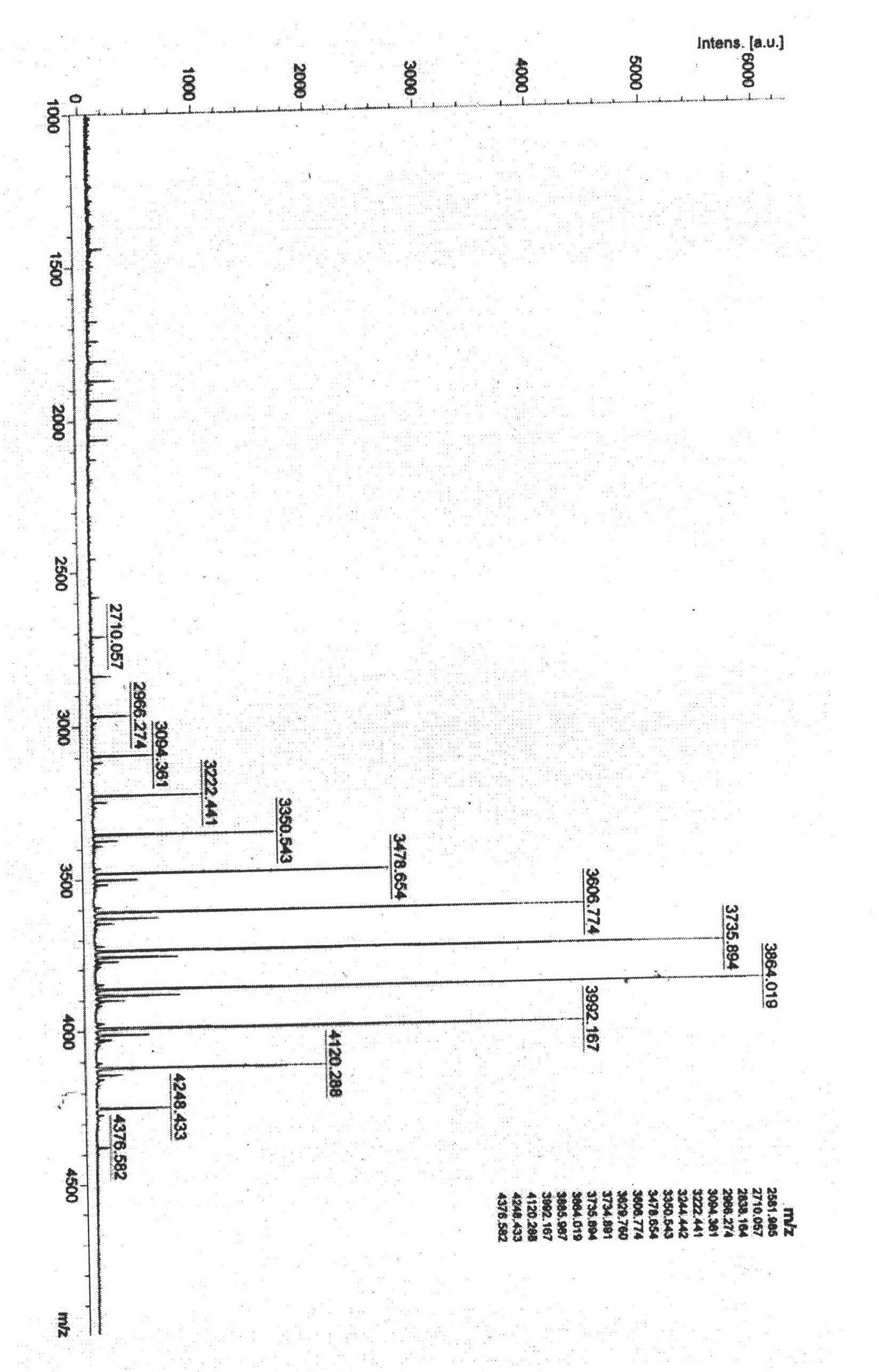

[0032] Embodiment 2, the shake flask method cultivation of starch hydrolysis sugar as single carbon source

[0033]Pick a ring of spores from Streptomyces sp.NK49 preserved on the slant of Benet and inoculate it into a 500ml Erlenmeyer flask containing 100ml of seed medium Gao's No. 1 medium, activate culture at 30°C, 180rpm, and activate for 24h The activated seed culture is inoculated into No. 1 Gao's culture medium with 10% inoculum size (adopting 500ml Erlenmeyer flask during shake flask fermentation, liquid capacity is 100ml) as seed liquid 30 ℃, 180rpm cultivates 24h; 15% of the inoculum size was inoculated in 10 bottles of starch hydrolysis sugar synthesis medium (500ml Erlenmeyer flask was used during the shake flask fermentation, and the filling volume was 100ml) to ferment at 30°C and cultivated at 180rpm for 80h; Centrifuge at 8000rpm for 20min, discard the bacteria, and collect the supernatant; use the D152 weak acid type cation exchange resin for product adsorptio...

Embodiment 3

[0034] Embodiment 3, with starch hydrolysis sugar and glycerol as the shaking flask method culture of mixed carbon source

[0035] (1) Pick a ring spore from the Streptomyces sp.NK49 preserved on the slope of Benet and inoculate it into a 500ml Erlenmeyer flask containing 100ml of seed medium Gaoshi No. 1 medium, and activate it at 30°C and 180rpm , Activation 24h; The activated seed culture is inoculated to Gao Shi No. 1 medium with 10% inoculum size (adopting 500ml Erlenmeyer flask during shake flask fermentation, and the filling capacity is 100ml) as seed liquid 30 ℃, 180rpm cultivates 24h; The seed solution was inoculated in 10 bottles of starch hydrolysis sugar and glycerol synthesis medium with 15% inoculum amount (500ml Erlenmeyer flask was used during the shake flask fermentation, and the liquid volume was 100ml) as the seed solution at 30°C, and cultivated at 180rpm for 96h; After the end, the culture was centrifuged at 8000rpm for 20min, the bacteria were discarded, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com