Moisture/ultraviolet double-curing organic silicon adhesive

A UV and dual-curing technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem that it is difficult to achieve complete curing in light-curing systems, and achieve excellent temperature resistance and deep curing depth , the effect of meeting the application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

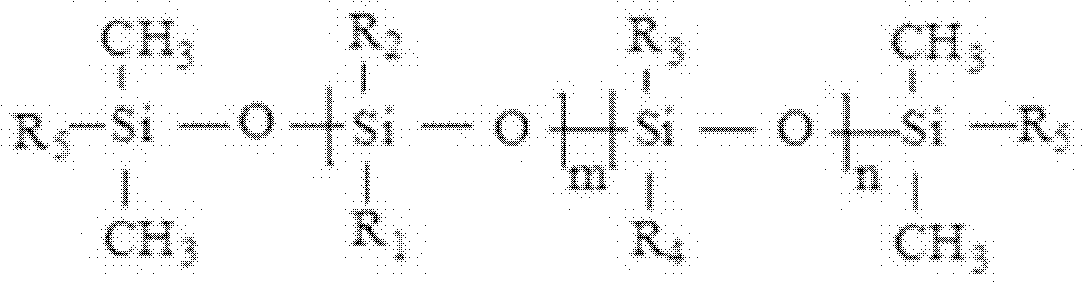

Method used

Image

Examples

Embodiment 1

[0016] The ultraviolet-moisture dual-curing silicone adhesive of the present invention is made of the following raw materials in parts by weight: methacryloyloxyethoxyalkoxypolysiloxane: 100 parts; silane coupling agent KH570: 20 parts; Silicon macromolecular photoinitiator: 4 parts; accelerator triethylamine: 0.7 part; polymerization inhibitor hydroquinone: 0.5 part; catalyst organotin: 1 part; filler calcium carbonate: 5 parts.

Embodiment 2

[0018] The ultraviolet-moisture dual-curing silicone adhesive of the present invention is made of the following raw materials in parts by weight: methacryloyloxyethoxyalkoxypolysiloxane: 120 parts; silane coupling agent KH570: 15 parts; benzoin Dimethyl ether photoinitiator: 5 parts; accelerator triethylamine: 0.8 parts; polymerization inhibitor hydroquinone: 0.4 parts; catalyst organotin: 2 parts; filler silica: 2 parts.

Embodiment 3

[0020] The ultraviolet-moisture dual-curing silicone adhesive of the present invention is made of the following raw materials in parts by weight: vinyl alkoxy polysiloxane: 160 parts; silane coupling agent KH570: 40 parts; silicon-containing macromolecular photoinitiator : 5 parts; 2-methyl-2-hydroxy-1-phenyl-1-propanone: 1 part; accelerator triethylamine: 1 part; polymerization inhibitor hydroquinone: 0.1 part; catalyst tin chelate : 1 part; filler titanium dioxide: 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com