Nano grating mask preparation method for surface plasma photoetching

A technology of surface plasmon and nano-grating, which is applied in the photoplate-making process of patterned surface, optical mechanical equipment, optics, etc., can solve the problems of difficult preparation of grating, difficult preparation, high price, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, using a photoresist grating with a period of 200nm to fabricate a silicon grating array with a period of 50nm, the fabrication process is as follows:

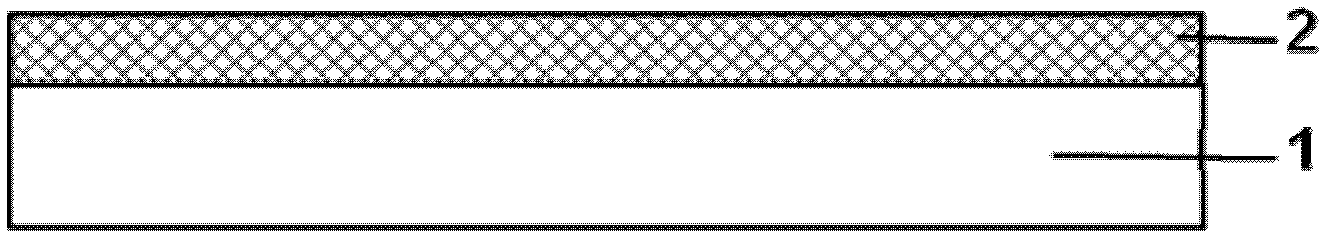

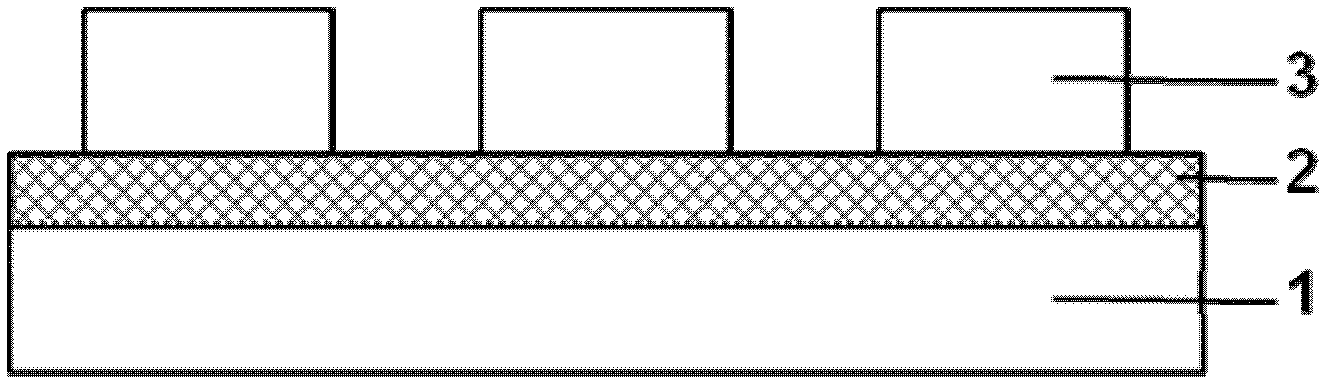

[0037] (1) Plating 50nm silicon on a quartz substrate, such as figure 1 As shown, then a grating array with a period of 200nm and a photoresist line width of 120nm is prepared on the substrate by an interference lithography method with a light source of 365nm laser, as figure 2 shown;

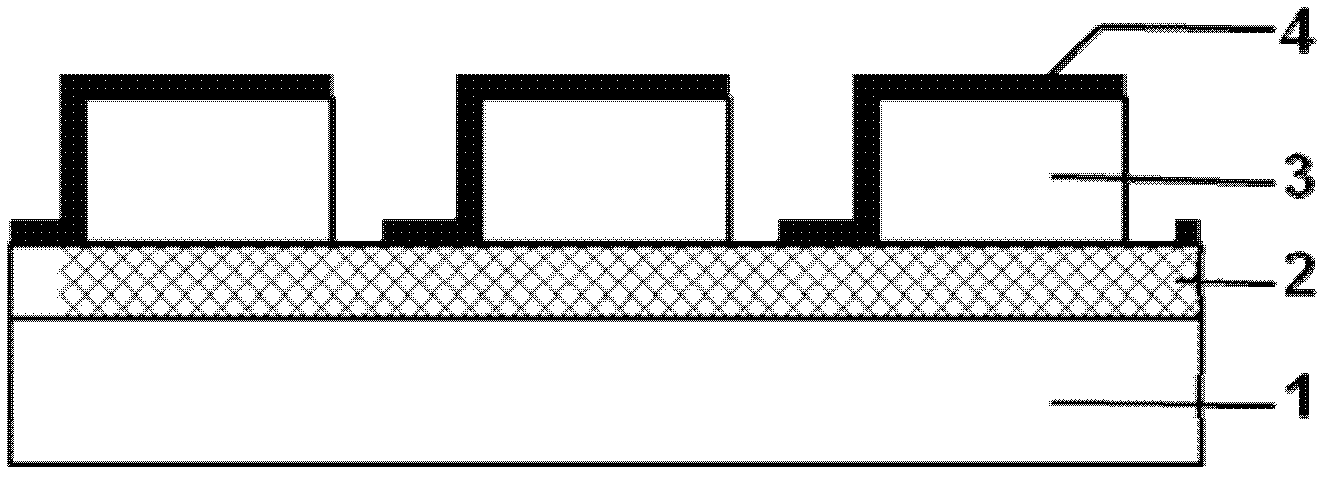

[0038] (2) Towards the right side of the grating lines, shadow evaporated chromium is used as a masking layer, and a narrow slit with a width of 30nm without a chromium masking film layer is obtained on the right side of each grating line, as image 3 shown;

[0039] (3) Use SF 6 The gas performs anisotropic RIE method to etch a 50nm silicon film layer, and it will stop when it reaches the quartz material, such as Figure 4 shown;

[0040] (4) Remove the chromium masking layer to obtain a group of narrow slit lines tha...

Embodiment 2

[0044] Embodiment 2, a germanium grating array with a period of 40nm is produced with a photoresist grating with a period of 160nm, and the production process is as follows:

[0045] (1) Plating 40nm germanium on a glass substrate, then using a 257nm laser as a light source to carry out interference lithography, and preparing a photoresist grating array with a period of 160nm and a photoresist line width of 100nm on the substrate;

[0046] (2) Carry out shadow vapor deposition of copper as a masking layer to one side of the grating lines, and obtain a narrow slit with a width of 20nm without a copper masking film layer on the side of each grating line;

[0047] (3) Carry out the anisotropic RIE method to etch through the germanium film layer, and stop automatically when the glass material is etched;

[0048] (4) removing the copper masking layer to obtain a group of narrow slit lines that are etched and transferred to the germanium substrate;

[0049](5) Then perform shadow v...

Embodiment 3

[0052] Example 3, an aluminum grating array with a period of 30nm is produced with an imprinted rubber grating with a period of 120nm, and the production process is as follows:

[0053] (1) Plating 30nm of aluminum on a flat copper substrate, and then preparing a grating array with a period of 120nm and an embossing glue line width of 75nm on the substrate by a nanoimprint method;

[0054] (2) Towards the right side of the grating lines, shadow evaporated silver is used as a masking layer, and a narrow slit with a width of 15nm without silver masking film layer is obtained on the right side of each grating line;

[0055] (3) Carry out anisotropic RIE method to etch the aluminum film layer of 30nm;

[0056] (4) remove the silver masking layer to obtain a group of slit lines that are etched and transferred to the aluminum film layer;

[0057] (5) Then shadow evaporate the silver masking layer, RIE etching, and remove the silver masking layer to the other side of the grating lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com