Method for rapidly preparing solid-phase microextraction fiber coating

A technology for extracting fibers and coatings, which is applied in the fields of analytical chemistry and environmental analysis. It can solve the problems of easy shedding, short service life, and low output, and achieve the effects of uniform coating, advanced thinking, and simple coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

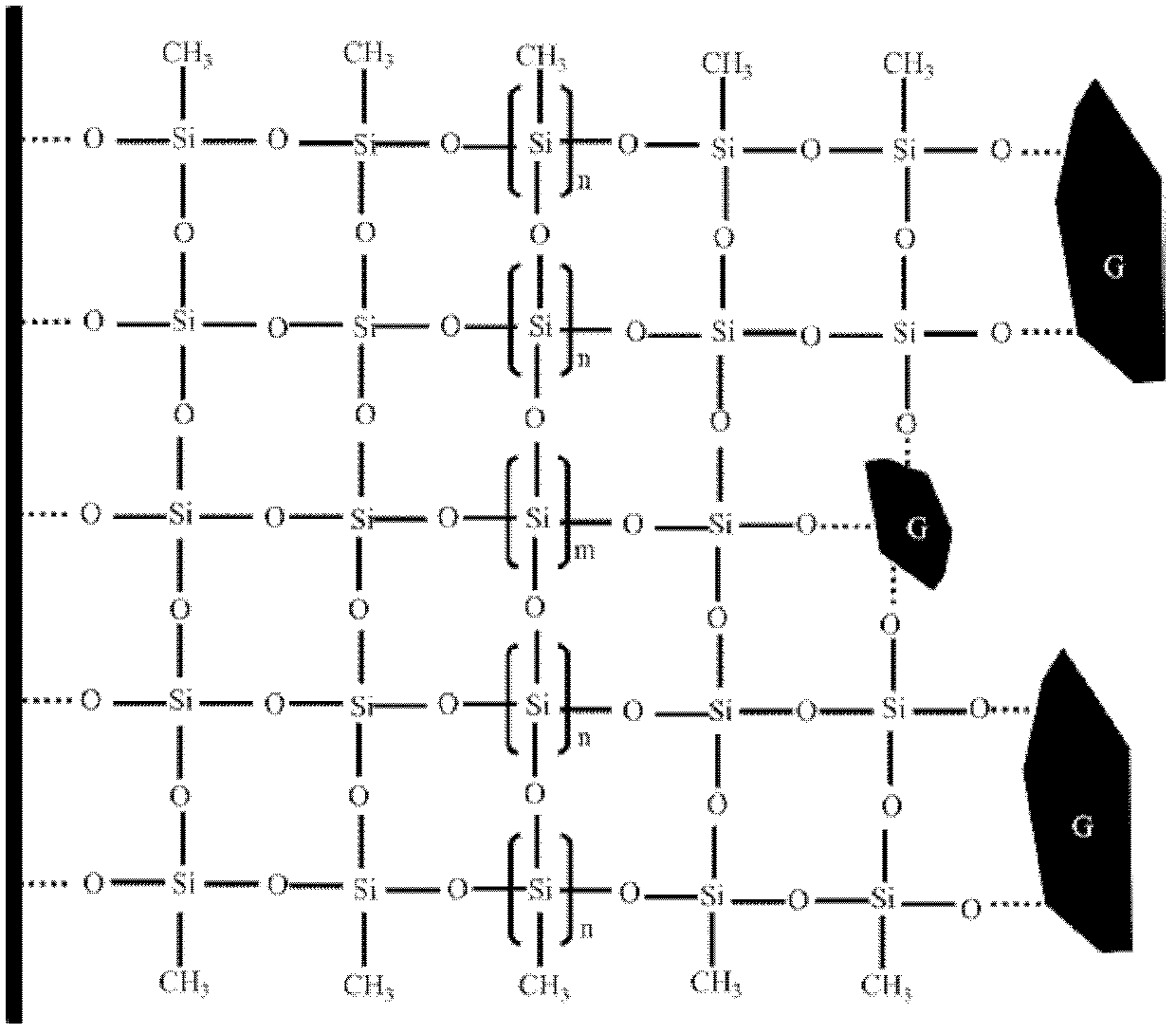

[0031] 1) Take a certain amount of rubber monomer PDMS monomer and match the curing agent used at the same time according to the volume ratio of 10:1 and mix evenly to obtain a viscous carrier coating (that is, polydimethylsiloxane). Put it into a vacuum drying oven, evacuate until no bubbles escape, and take it out for use;

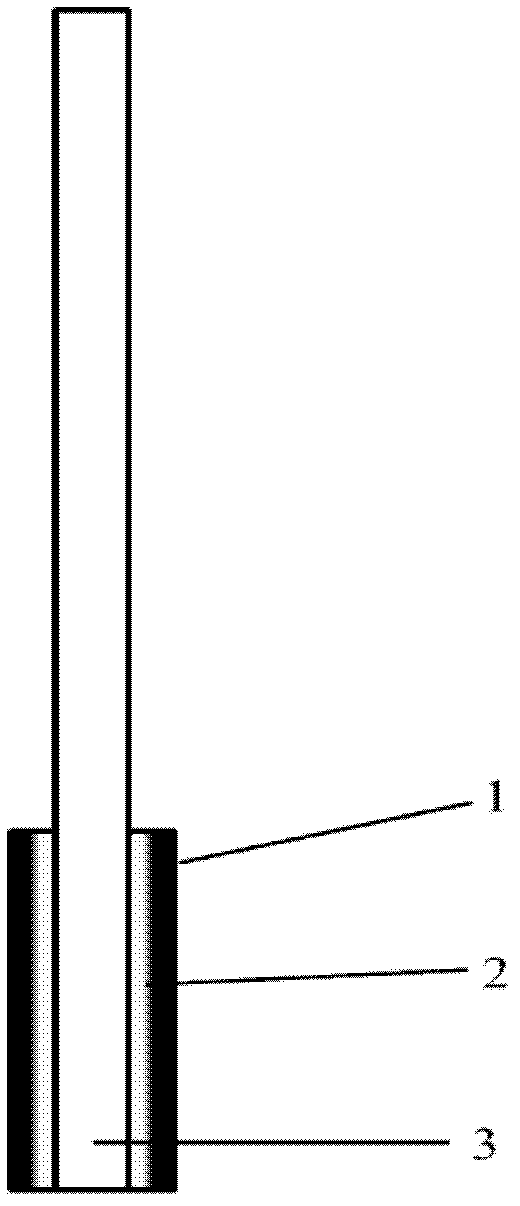

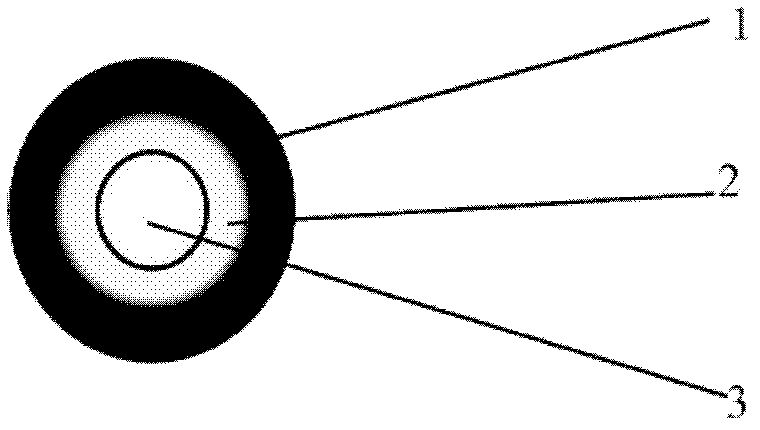

[0032] 2) Take a solid-phase microextraction fiber stainless steel needle with a diameter of 250 μm, insert it into a stainless steel tube with an inner diameter of 320 μm, burn it on an alcohol lamp for a few seconds, and then insert it directly into the vacuum-degassed viscous carrier coating obtained in the above step 1), Take it out after 1 second, remove the sleeve, and get a 35 μm thick adhesive carrier coating; then insert it into the graphene solid powder of the coating material, and then insert the sleeve stainless steel tube with an inner diameter of 400 μm, pump it back and forth several times to homogenize Graphene coating to obtain a functio...

Embodiment 2

[0037] The prepared graphene-based SPME was compared with commercial SPME using the following scheme:

[0038] 1) Use commercial SPME with 100 μm thick PDMS to extract the volatiles from the cow beetle at room temperature for 2 minutes, then analyze the volatiles in GC-MS at 280°C for 1 minute, and then perform GC separation and MS detection. The results are shown in Figure 6 ;

[0039] 2) Use the SPME with graphene as the functional adsorption coating in Example 1 to extract the volatile matter on the female beetle under the same conditions, the extraction time is 2min, and then carry out the GC-MS analysis and separation and detection under the same conditions , get as Figure 7 The results shown.

[0040] It can be seen from the figure that the extraction efficiency of the graphene extraction head prepared in Example 1 is better than that of the 100 μm thick PDMS extraction head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com