Preparation method of high-activity low-expansion biological microcrystalline glass

A glass-ceramic, low-expansion technology, used in medical science, coatings, prostheses, etc., can solve the problems of unsuitable titanium alloy surface active coating materials and less research on biological glass-ceramic coating materials. The effect of improving mechanical properties and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

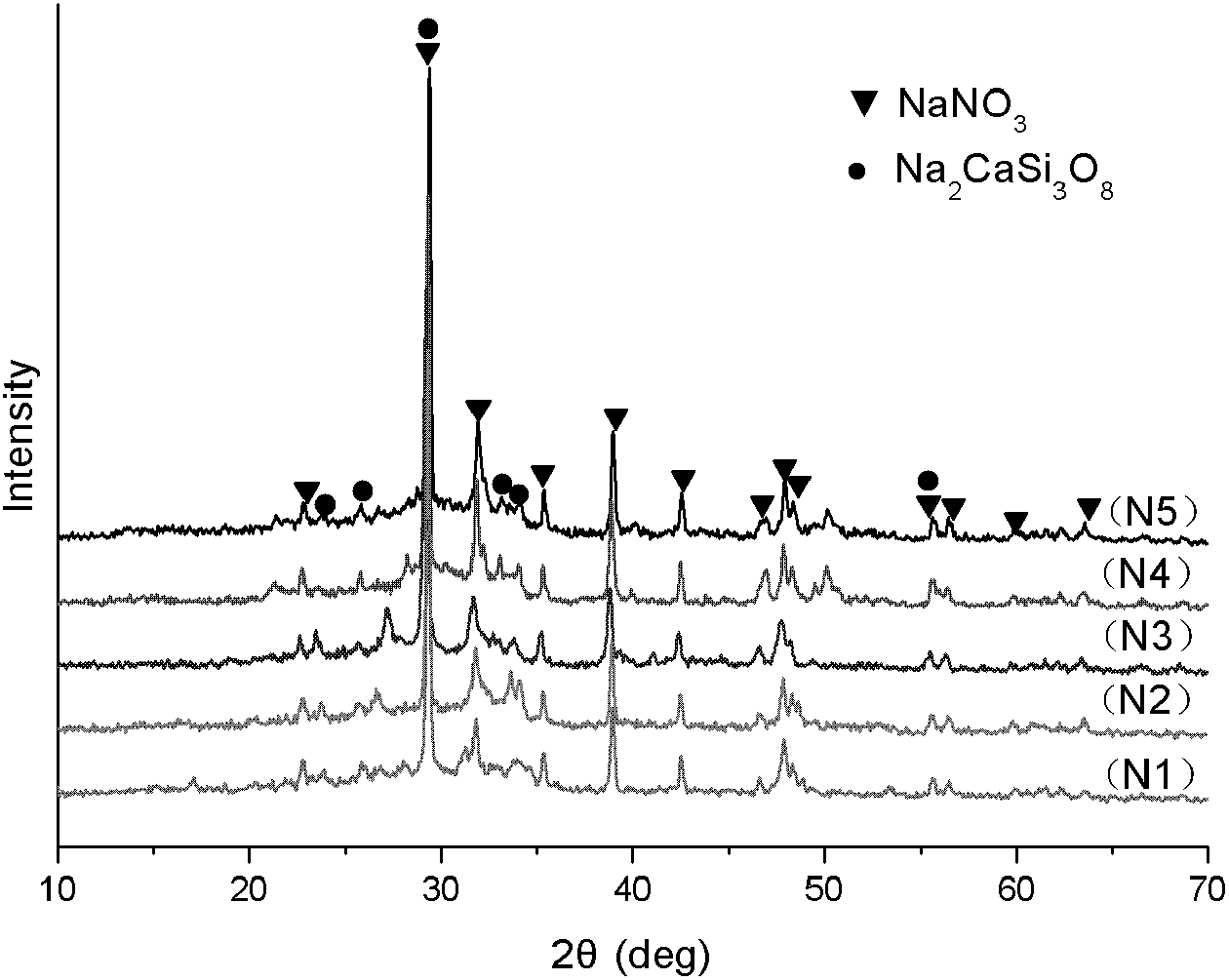

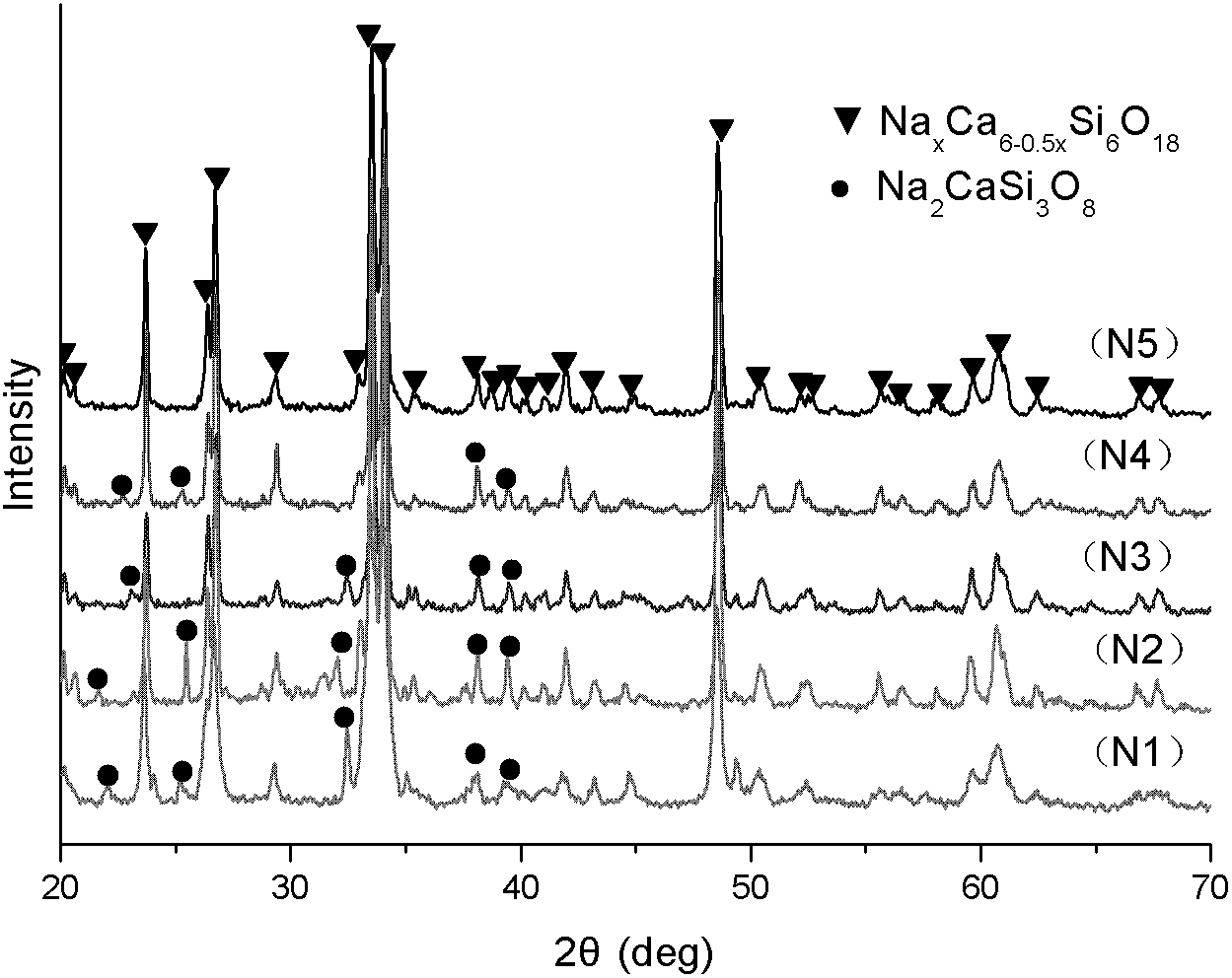

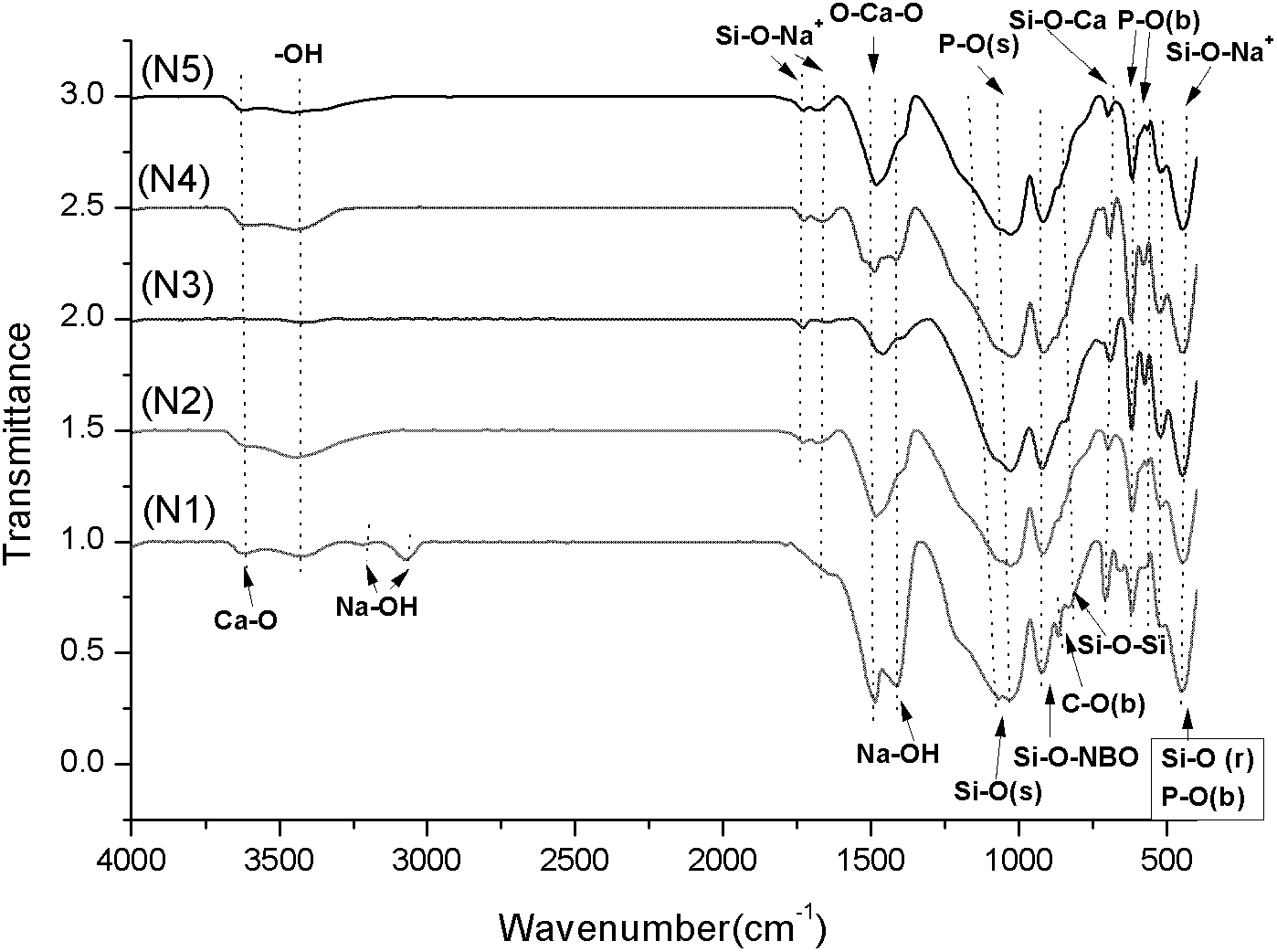

[0037] Embodiment 1: Preparation of 45S5 bioactive glass-ceramics (N1), the process is as follows:

[0038] Weigh orthoethyl silicate Si(OC) according to the ratio in Table 1-1 2 h 5 ) 4 , triethyl phosphate OP(OC 2 h 5 ) 3 , calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O, sodium nitrate NaNO 3 ; Under the catalysis of 25ml nitric acid solution (2mol / L), ethyl orthosilicate was pre-hydrolyzed for 30min under stirring in 208.77ml deionized water, then added triethyl phosphate for hydrolysis for 30min, then added calcium nitrate tetrahydrate and sodium nitrate And stir to fully dissolve to form a clear sol; place the clear sol in an airtight container at room temperature for 3 days, after it forms a gel, put it in a constant temperature water bath at 60°C for aging treatment for 3 days, and place the obtained semi-dry gel in Dried in a drying oven to obtain a dry gel;

[0039] The obtained xerogel is ball milled in a ball mill and sieved to 200 meshes to obtain glass ...

Embodiment 2

[0044] Embodiment 2: preparation adds K 2 O bioactive glass-ceramics (N2) with 6 mol% K 2 O replaces 6 mol% CaO in 45S5, the process is as follows:

[0045] Weigh orthoethyl silicate Si(OC 2 h 5 ) 4 , triethyl phosphate OP(OC 2 h 5 ) 3 , calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O, sodium nitrate NaNO 3 , potassium nitrate KNO 3 ; Under the catalysis of 25ml nitric acid solution (2mol / L), ethyl orthosilicate was pre-hydrolyzed for 30min under stirring in 208.77ml deionized water, then added triethyl phosphate for hydrolysis for 30min, then added calcium nitrate tetrahydrate and sodium nitrate , potassium nitrate and stir to dissolve fully to form a clear sol; place the clear sol in an airtight container at room temperature for 6 days, and after it forms a gel, put it in a constant temperature water bath at 60°C for aging treatment for 3 days, and the obtained semi-dry The gel is placed in a drying oven to dry to obtain a dry gel;

[0046] The obtained xerogel ...

Embodiment 3

[0051] Embodiment 3: preparation adds B 2 o 3 Bioactive glass-ceramic (N3) with 6 mol% B 2 o 3 To replace 6 mol% CaO in 45S5, the process is as follows:

[0052] Weigh orthoethyl silicate Si(OC 2 h 5 ) 4 , triethyl phosphate OP(OC 2 h 5 ) 3 , calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O, sodium nitrate NaNO 3 , boric acid H 3 BO 3 ; Under the catalysis of 25ml nitric acid solution (2mol / L), ethyl orthosilicate was pre-hydrolyzed for 30min under stirring in 208.77ml deionized water, then added triethyl phosphate for hydrolysis for 30min, then added calcium nitrate tetrahydrate and sodium nitrate , boric acid and stirred to fully dissolve to form a clear sol; the clear sol was placed in a closed container at room temperature for 3 days, and after it formed a gel, it was placed in a 60°C constant temperature water bath for aging treatment for 3 days, and the obtained semi-dry condensed The glue is placed in a drying oven to dry to obtain a dry gel;

[0053] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com