Preparation device of charcoal with biomass as raw material

A technology of biomass raw materials and preparation equipment, which is applied in the direction of biofuel, fixed carbonization furnace, special form of dry distillation, etc., and can solve problems such as environmental hazards, long carbon production cycle, and unutilized heat value of pyrolysis gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

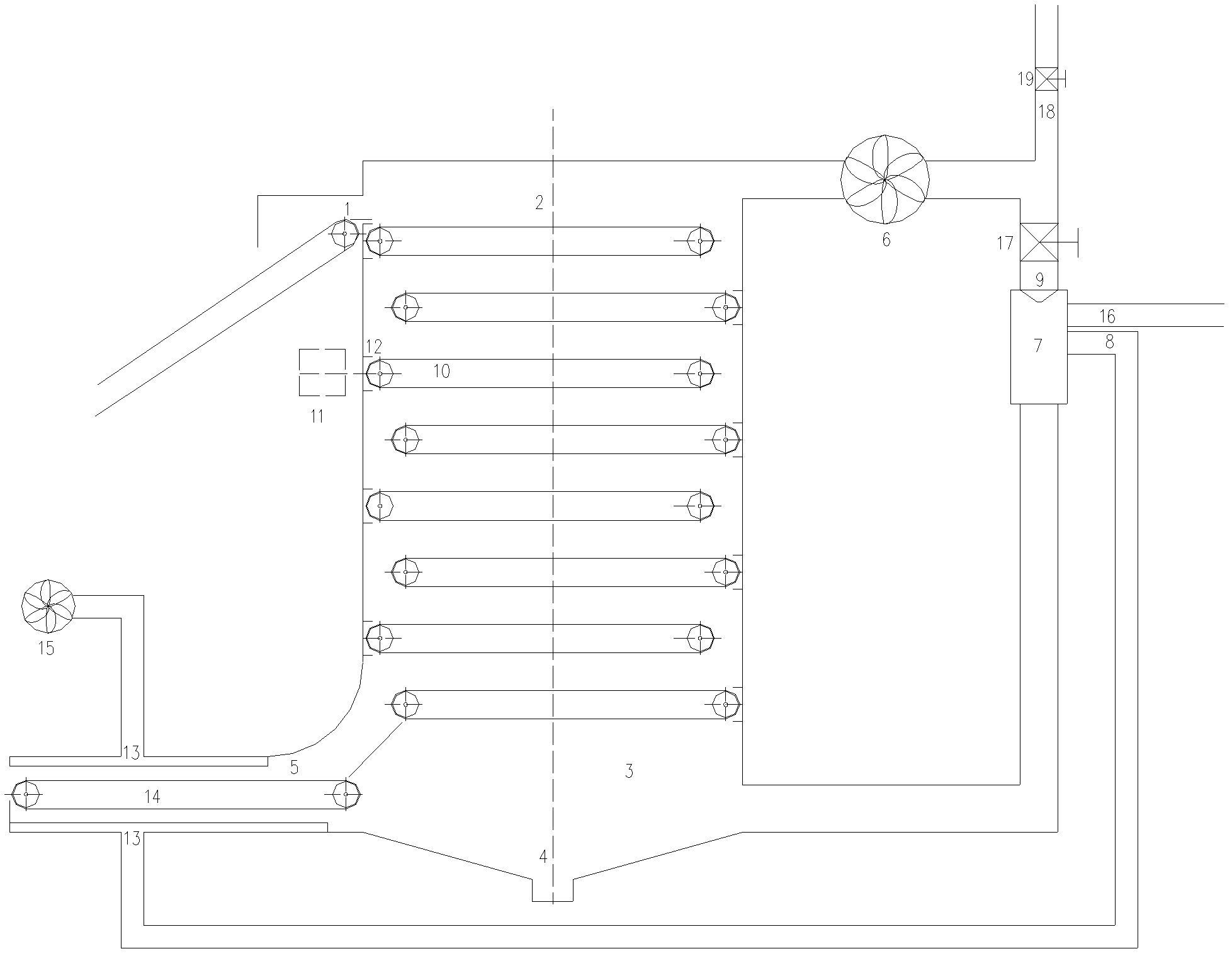

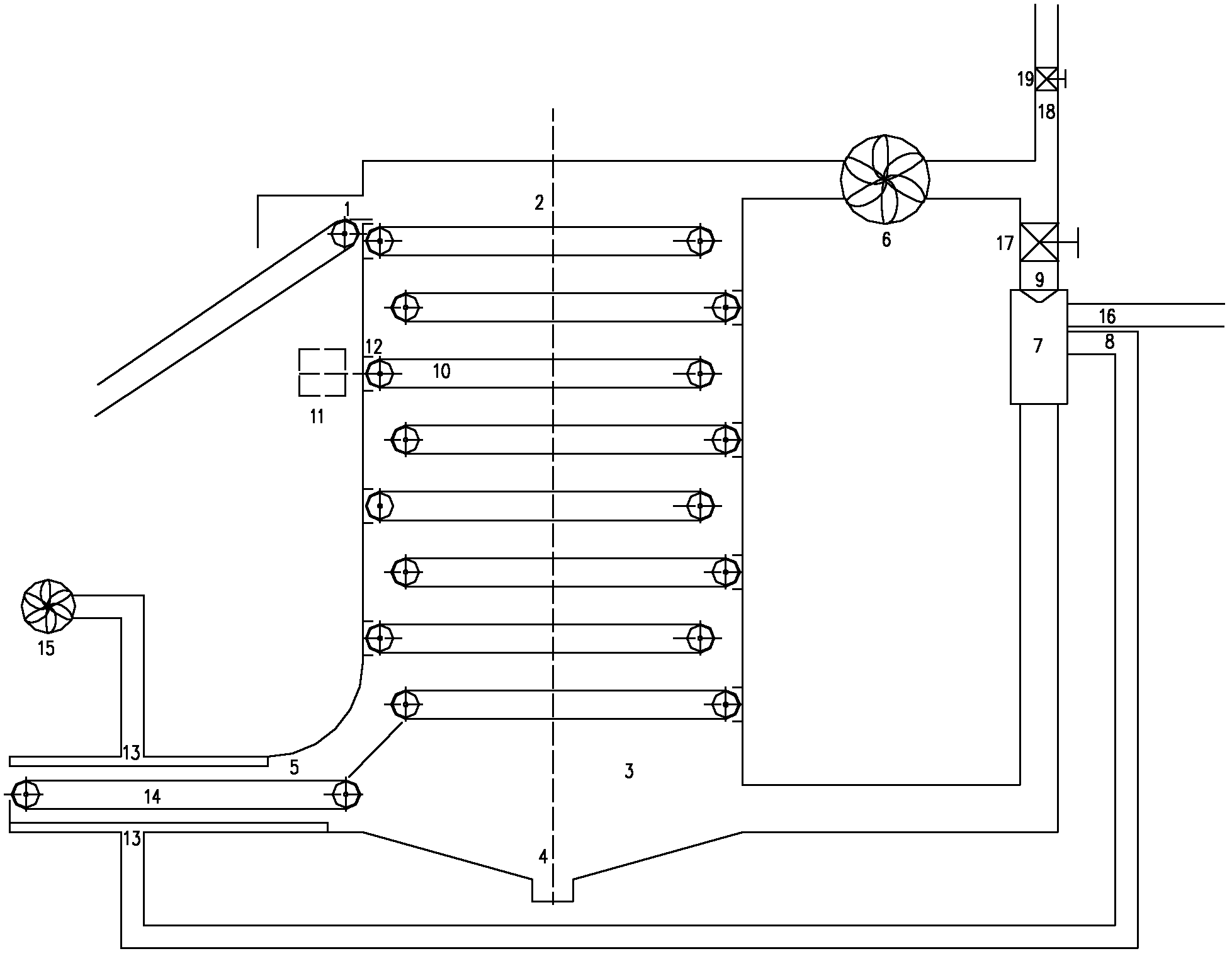

[0010] The main structure of this embodiment includes a top feeding device 1, a vertical furnace 2, a heat source flue gas inlet chamber 3, an ash chamber 4, a charcoal waste heat recovery chamber 5, an induced draft fan 6, a combustion chamber 7, a combustion air inlet 8, two Secondary air inlet pipe 9, grate 10, driving motor 11, sealing baffle 12, air interlayer 13, charcoal outlet grate 14, blower 15, gas inlet 16, flow regulating valve 17, venting pipe 18 and outlet flow regulating valve 19. In the inner cavity of the vertical furnace 2, there are 2 to 16 levels of fire grates 10 spaced from each other horizontally arranged up and down, and the top side of the vertical furnace 2 is provided with a top feed on the upper side of the first fire grate 10 in the upper part. Device 1, the top feeding device 1 adopts the output mode of chain belt or chain structure, so that the input combustion materials are neatly laid on the upper fire grate 10, and the two ends of each fire gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com