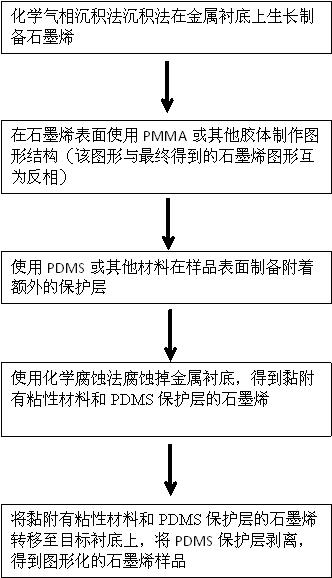

Transfer preparation method of patterned graphene

A technology for patterning graphene and graphene, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of graphene sample cracking, damage, solvent damage to the substrate, etc., to achieve the effect of keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

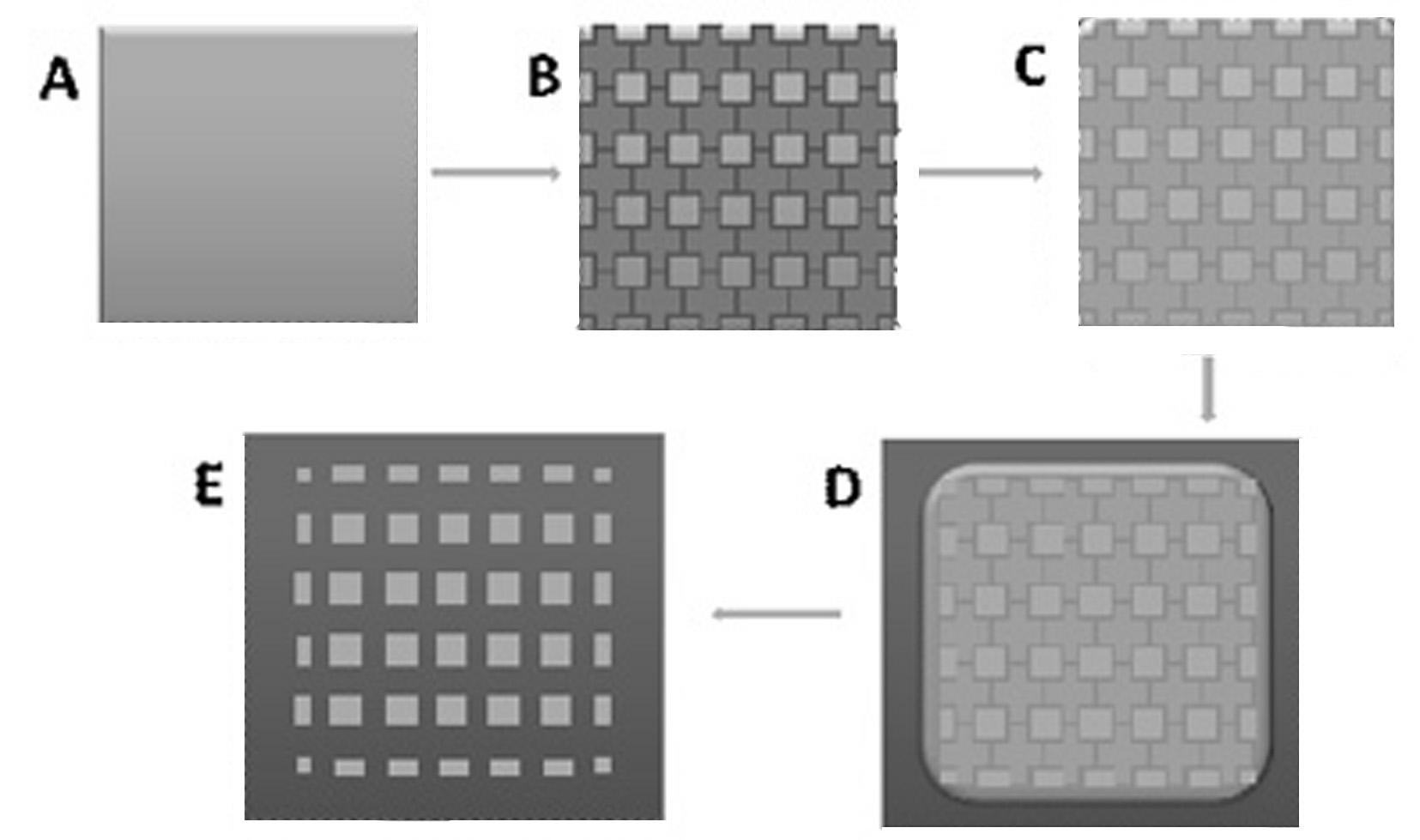

[0022] Use chemical vapor deposition to grow graphene on the surface of copper foil. The specific process: use hydrogen and methane as the gas source, place the copper foil in a tube furnace, heat the tube furnace to 1000 degrees Celsius in a vacuum environment, and feed The hydrogen of 2sccm and the methane of 35sccm and keep 15 minutes, turn off heating device, after the tube furnace is cooled to normal pressure, promptly grow the graphene of single layer on the surface of copper foil, as figure 2 a.

[0023] Use a glass fiber to dip a small amount of PMMA solution, and draw a grid-like structure on the surface of the graphene-grown copper foil. The size of the grid is about 1 mm, and the thickness of the grid lines is about 0.3 mm. Place the sample that has drawn the PMMA pattern in the air and let it stand for half an hour. After the solvent volatilizes, a patterned PMMA film is obtained on the graphene surface, such as figure 2 b. Printing or printing techniques can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com