Method for preparing inorganic-organic composite flocculant made of polymeric aluminum and modified compound biological flocculant

A technology of biological flocculant and composite flocculant, which is applied in the field of environment and chemistry, can solve the problems of negative charge limitation of wide and effective use, difficulty in realizing large-scale use, and high cost of graft modification, so as to reduce the cost of graft modification. , The effect of wide dosage range and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

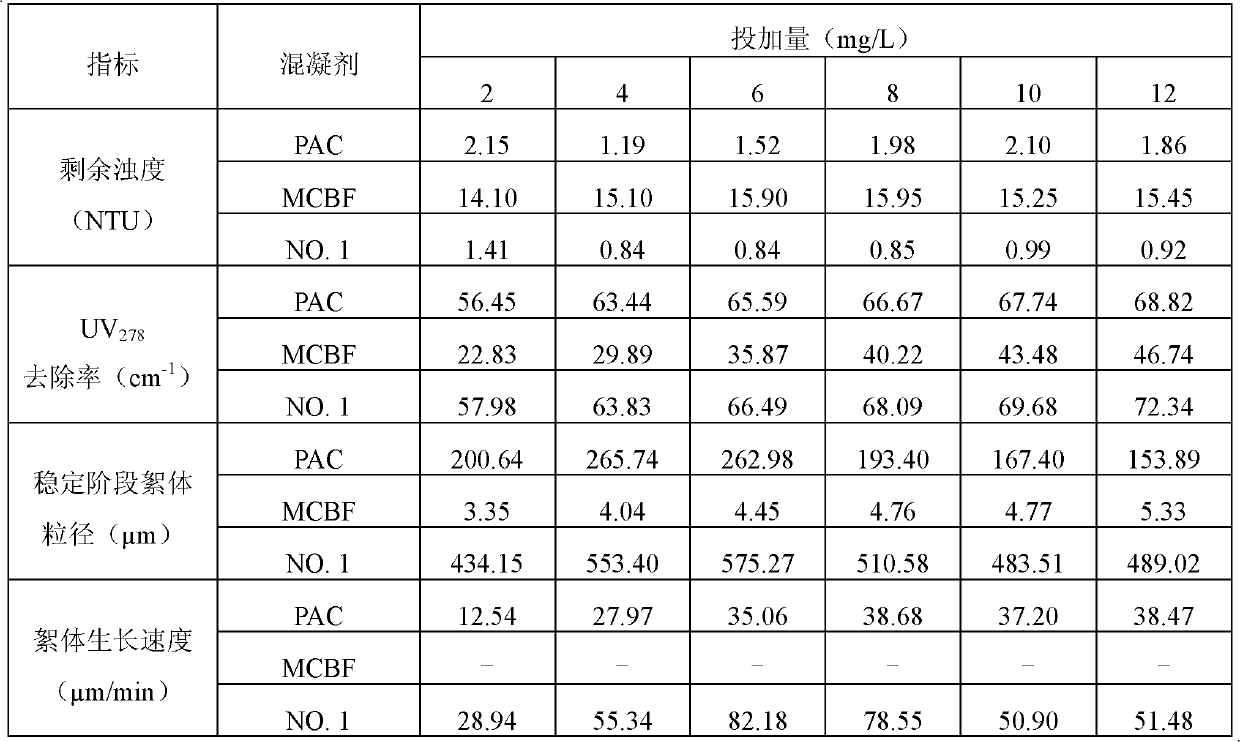

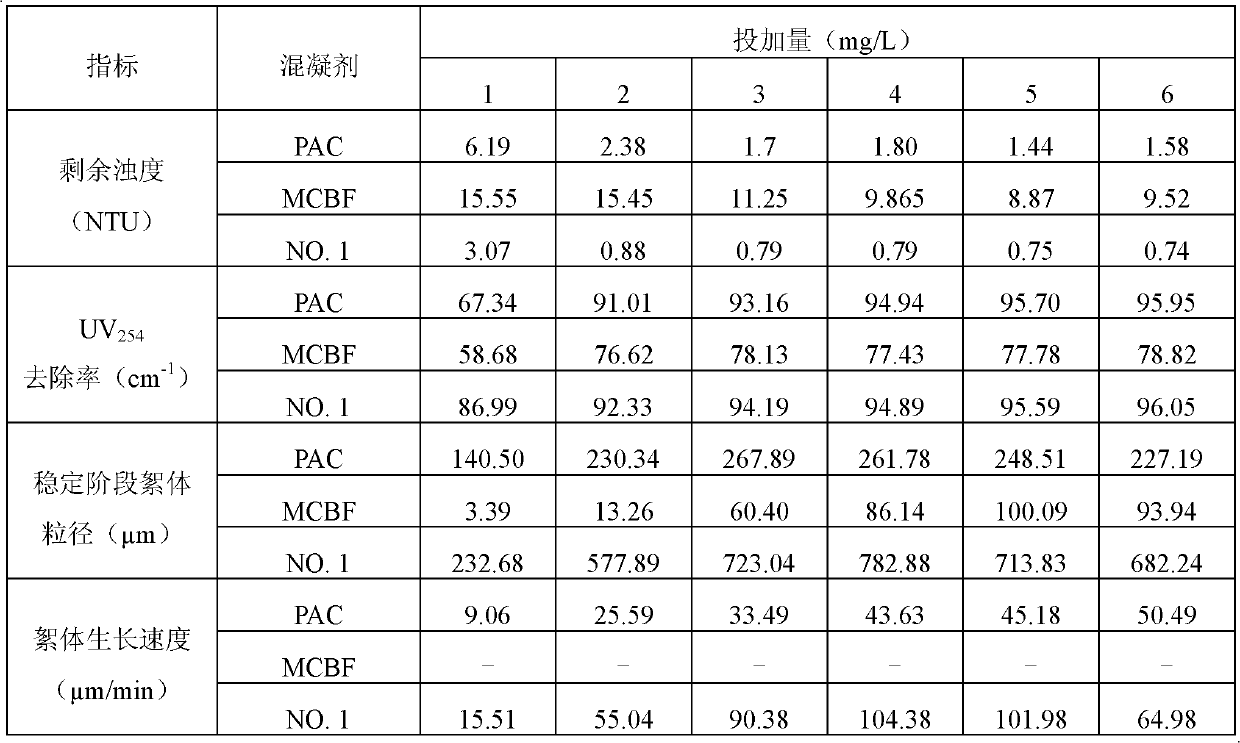

Embodiment 1

[0029] Example 1: Polymerized aluminum-modified composite bioflocculant inorganic-organic composite flocculant, the preparation method is as follows:

[0030] (1) Weigh 22.36g AlCl 3 ·6H 2 O solid in a beaker, add distilled water to dissolve, weigh Na 2 CO 3 4.91g was dissolved in water, and Na was added dropwise with stirring 2 CO 3 solution to AlCl 3 solution, stirred at room temperature to obtain a colorless transparent liquid, and prepared a PAC solution with a degree of alkalinity of 66%, dissolved AlCl 3 ·6H 2 O and Na 2 CO 3 The total amount of water used is 250ml.

[0031] (2) Weigh 1.0g of CBF, put it into a reactor equipped with a stirring device, add 30.0ml of deionized water to fully stir, and protect it under nitrogen. After the oxygen in the reaction vessel is exhausted, add the initiator potassium persulfate and place it in a water bath at 50°C Maintain the temperature for 15 minutes, then add sodium sulfite, acrylamide (AM) and dimethyl diallyl ammon...

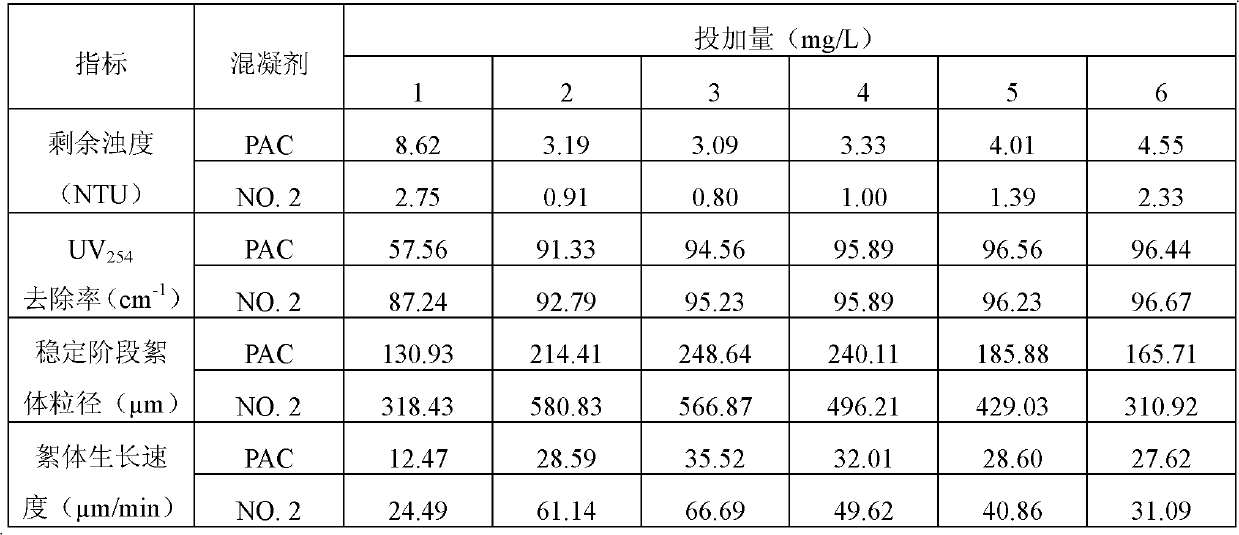

Embodiment 2

[0033] Embodiment 2: As described in Embodiment 1, the difference is:

[0034] Take 4.47g AlCl respectively 3 ·6H 2 O solid and 1.47 g Na 2 CO 3 The powder is dissolved in water to form a solution, and the Na 2 CO 3 The solution was added dropwise to AlCl 3 In the solution, the total amount of water is 250ml to a predetermined alkalization degree of 50%, and a PAC solution is prepared. The PAC-MCBF inorganic-organic composite flocculant was prepared by taking the PAC solution and the MCBF solution (2.5g / L) at a ratio of Al:MCBF mass ratio of 1:1. The product is represented by No.2.

Embodiment 3

[0035] Embodiment 3: As described in Embodiment 1, the difference is:

[0036] Take 4.47g AlCl respectively 3 ·6H 2 O solid and 0.98 g Na 2 CO 3 The powder is dissolved in water to form a solution, and the Na 2 CO 3 The solution was added dropwise to AlCl 3 In the solution, the total amount of water is 250ml to a predetermined alkalization degree of 33%, and a PAC solution is prepared. The PAC-MCBF inorganic-organic composite flocculant was prepared by taking the PAC solution and the MCBF solution (2.5g / L) at a ratio of Al:MCBF mass ratio of 1:1. The product is represented by No.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com