Synthesis method of styrene/acrylate-modified quick-drying water-based alkyd resin

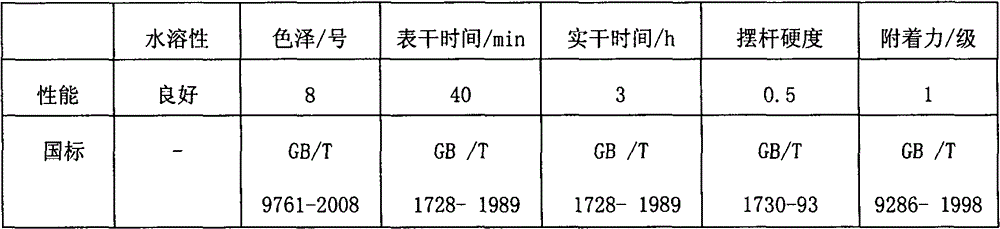

A water-based alkyd resin, alkyd resin technology, applied in the direction of coating, can solve the problems of low hardness and slow drying rate, and achieve the effect of improving gloss, increasing efficiency and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

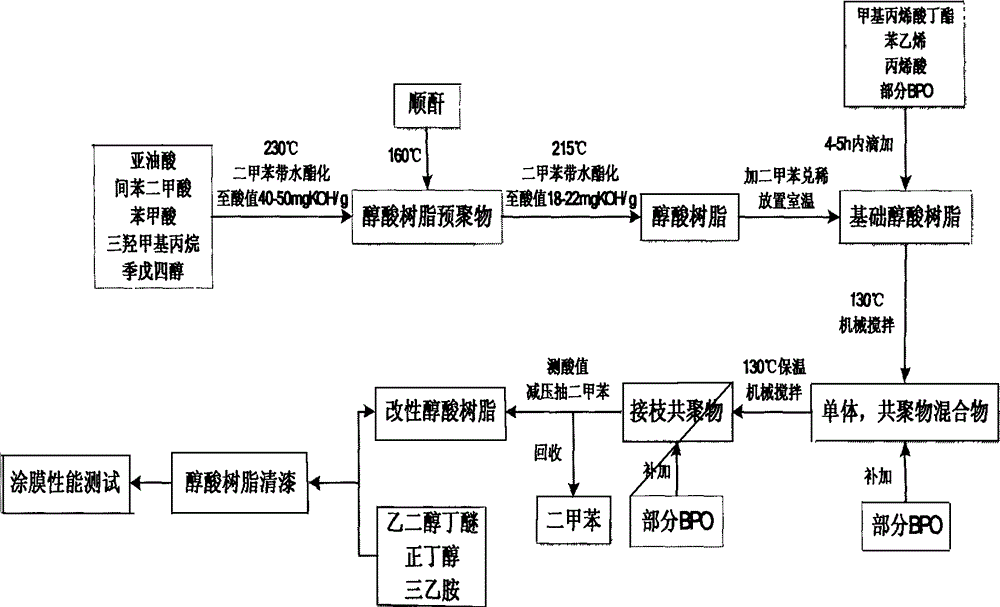

Method used

Image

Examples

Embodiment 1

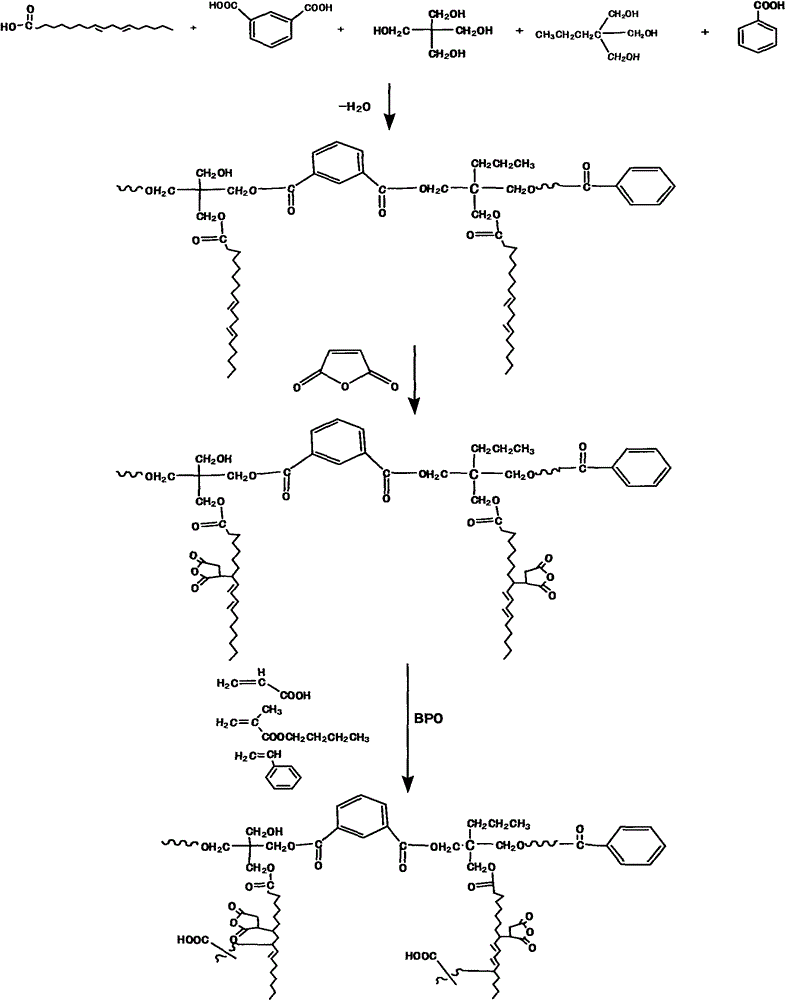

[0023] a. Synthesis of basic alkyd resin: Add 144g of linoleic acid, 21.0g of benzoic acid, 42.0g of isophthalic acid, 15.0g of pentaerythritol, 57.0g of trimethylolpropane and 60mL of xylene into a 1000mL three-necked flask in turn, start Stir mechanically, raise the temperature to 180°C, slowly raise the temperature to 230°C within 1 hour, after the acid value drops to 40-50mgKOH / g, cool down to 160°C, add 6.9g maleic anhydride, then raise the temperature to 200°C, and keep warm for esterification to Stop heating after the acid value drops to 18-22mgKOH / g, drop to room temperature, and obtain the basic alkyd resin for subsequent use;

[0024] b. Modification of basic alkyd resin: add 60.0g of styrene, 90.1g of butyl methacrylate, and acrylic acid to the basic alkyd resin obtained in step a within 4-5 hours at a temperature of 130°C. 36.2g and the mixed solution of 3.3g of 50% initiator benzoyl peroxide accounting for 3% of the total amount of modified monomers. Benzoyl 1.6g...

Embodiment 2

[0026] a. Synthesis of basic alkyd resin: Add 144g of linoleic acid, 21.0g of benzoic acid, 42.0g of isophthalic acid, 15.0g of pentaerythritol, 57.0g of trimethylolpropane and 60mL of xylene into a 1000mL three-necked flask in turn, start Stir mechanically, raise the temperature to 180°C, slowly raise the temperature to 230°C within 1 hour, after the acid value drops to 40-50mgKOH / g, cool down to 160°C, add 6.9g maleic anhydride, then raise the temperature to 200°C, and keep warm for esterification to Stop heating after the acid value drops to 18-22mgKOH / g, drop to room temperature, and obtain the basic alkyd resin for subsequent use;

[0027] b. Modification of basic alkyd resin: add 69.8 g of styrene, 132.0 g of butyl methacrylate, and 39.0 g of acrylic acid to the basic alkyd resin obtained in step a within 4-5 hours at a temperature of 130 ° C. g and 50% initiator benzoyl peroxide 3.1g mixed solution accounting for 3% of the total amount of the modified monomer, after bei...

Embodiment 3

[0029] a. Synthesis of basic alkyd resin: add 144g of linoleic acid, 21.0g of benzoic acid, 42.0g of isophthalic acid, 15.0g of pentaerythritol, 57.0g of trimethylolpropane and 60mL of xylene into a 1000mL three-necked flask in turn, start Stir mechanically, heat up to 180°C, slowly heat up to 230°C within 1 hour, after the acid value drops to 40-50mgKOH / g, cool down to 160°C, add 6.9g maleic anhydride, then heat up to 200°C, keep warm for esterification to Stop heating after the acid value drops to 18-22mgKOH / g, drop to room temperature, and obtain the basic alkyd resin for subsequent use;

[0030] b. Modification of the basic alkyd resin: Add the modified monomers to the basic alkyd resin obtained in step a within 4-5 hours at a temperature of 130°C to 64.8g of styrene, 136.5g of butyl methacrylate, and 39.3g of acrylic acid g and 50% initiator benzoyl peroxide 3.6g mixed solution accounting for 3% of the total amount of the modified monomer, after being incubated for 1h, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com