Automatic ready-made jeans garment washing system and washing method thereof

A technology for clothing and denim, which is applied in the field of automatic denim clothing washing water system, can solve the problems of slow promotion of cleaning technology, limited number of denim clothing, and no application method found, so as to reduce waste water treatment and environmental load, Enables flexibility, increased security and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

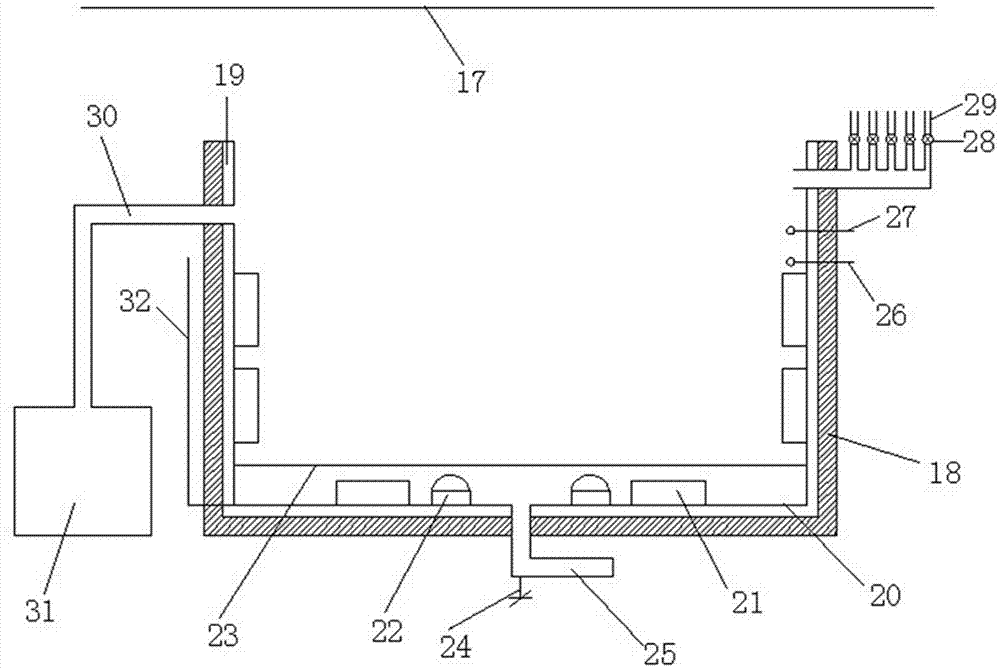

[0060]Taking the application of the washing process of hydrogen peroxide rinsing denim garments in this washing water system as an example, the denim garments that need to be washed are fixed on the hangers, and the samples are sent through the automatic garment hanging conveying system at a speed of 10 m / min. . Add hydrogen peroxide, caustic soda, hydrogen peroxide stabilizer, penetrant, whitening agent and other additives, adjust the ratio according to the metering pump, and add it into the washing pool based on ultrasonic denim clothing through the sampling tube, turn on the ultrasonic device, and adjust the ultrasonic power to 500W. Frequency 20KHz-25KHz. Turn on the intelligent temperature control system to keep the temperature of the washing liquid constant at 95 degrees, and then transport the delivered denim garments to the washing pool for washing by the suspension system. Liquid ultrasonic cleaning tank, ultrasonic power is 1kW, frequency 25kHz, remove the chemical ...

Embodiment 2

[0062] Taking the application of the washing process of biological enzyme enzyme washing denim clothing in this washing water system as an example, the denim clothing that needs to be washed is fixed on the hanger, and the sample is sent through the automatic clothing hanging conveying system at a speed of 1 meter. / minute. Add enzymes, citric acid-tripolyphosphate buffer, penetrant, anti-staining salt and other additives, adjust the ratio according to the metering pump, add the sample tube into the washing pool based on ultrasonic denim clothing, turn on the ultrasonic device, and adjust the ultrasonic Power 100W, frequency 20KHz-25KHz. Turn on the intelligent temperature control system to keep the temperature of the washing liquid constant at 60 degrees, and then transport the denim garments sent to the washing pool by the suspension system for washing. The washed denim garments are transported to the washing machine by the suspension system Liquid ultrasonic cleaning pool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com