Thin-film packaging component, photoelectronic device and packaging method of photoelectronic device

An optoelectronic device and thin film packaging technology, applied in the field of optoelectronics, can solve the problems of limiting the service life of OLEDs and the inability to use flexible flat-panel displays, and achieve the effects of reducing packaging costs, prolonging service life, and blocking damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

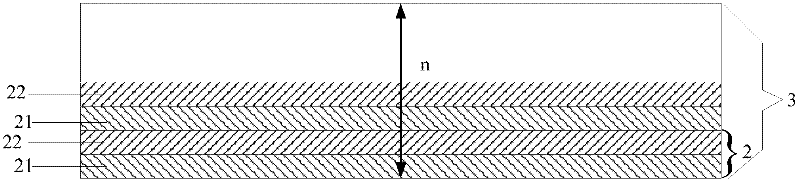

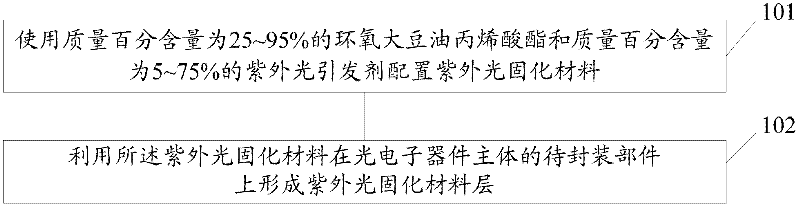

[0073] Example 1 The packaging method of an organic electroluminescent device and the packaged organic electroluminescent device, the flow chart of the packaging method of the organic electroluminescent device is shown in Figure 3, and the packaged organic electroluminescent device is as follows Figure 4 shown.

[0074] 201. Synthetic epoxy soybean oil acrylate:

[0075] Add epoxy soybean oil and polymerization inhibitor hydroquinone into the reaction vessel in proportion, heat the reaction, add catalyst N,N-dimethylaniline and acrylic acid at 120°C, and reflect until the acid value of the system drops to 8mgKOH / g, stop the reaction to obtain epoxy soybean oil acrylate. Wherein, the molar ratio of epoxidized soybean oil to acrylic acid is 1.2:1, the catalyst accounts for 1% of the total mass of all reactants, and the polymerization inhibitor accounts for 0.1% of the total mass of all reactants.

[0076] 202. Configure UV curing materials:

[0077] After mixing the synthes...

Embodiment 2

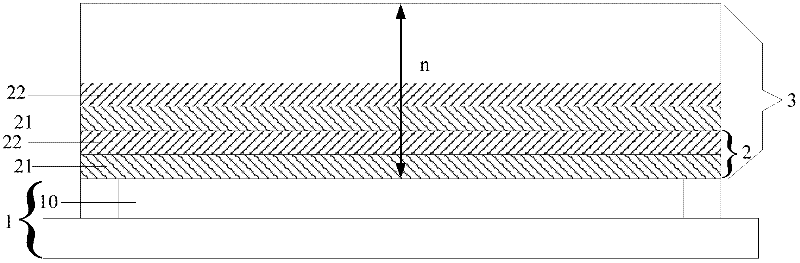

[0088] Embodiment 2 The encapsulation method of the organic solar cell device and the organic solar cell device after the encapsulation, the organic solar cell device after the encapsulation is as follows Figure 5 shown.

[0089] The encapsulation method includes:

[0090] 301. Synthetic epoxy soybean oil acrylate:

[0091] Add epoxidized soybean oil and polymerization inhibitor p-hydroxyanisole into the reaction vessel in proportion, heat the reaction, add the catalyst triphenylphosphine and acrylic acid at 100°C, and reflect until the acid value of the system drops to 8mgKOH / g, Stop reaction, obtain epoxidized soybean oil acrylate, wherein, the mol ratio of epoxidized soybean oil and acrylic acid is 1.12: 1, catalyst accounts for 1.2% of all reactants gross mass, and polymerization inhibitor accounts for 0.12% of all reactants gross mass .

[0092] 302. Configure UV curing materials:

[0093] The synthesized epoxy soybean oil acrylate is mixed with the active diluent tr...

Embodiment 3

[0104] Embodiment 3 The packaging method of the organic thin film transistor device and the packaged organic thin film transistor device, the packaged organic thin film transistor device is as follows Figure 6 shown.

[0105] The methods include:

[0106] 401. Synthetic epoxy soybean oil acrylate:

[0107] Add epoxidized soybean oil, polymerization inhibitor tris (N-nitroso-N-phenylhydroxylamine) aluminum salt in proportion to the reaction vessel, heat the reaction, add catalyst p-methoxycresol and Acrylic acid, when reflecting until system acid value drops to 8mgKOH / g, stops reaction, obtains epoxidized soybean oil acrylate. Wherein, the molar ratio of epoxidized soybean oil to acrylic acid is 1.2:1, the catalyst accounts for 2% of the total mass of all reactants, and the polymerization inhibitor accounts for 0.5% of the total mass of all reactants.

[0108] 402. Configure UV curing materials:

[0109] After mixing the synthesized epoxy soybean oil acrylate and the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com