Nano water-soluble emulsion and preparation method thereof

A water-soluble, emulsion technology, applied in food preparation, emulsion transportation, pharmaceutical formulations, etc., can solve problems such as difficult to achieve uniform particle emulsification particles, and achieve the effect of improving absorption and utilization and improving digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

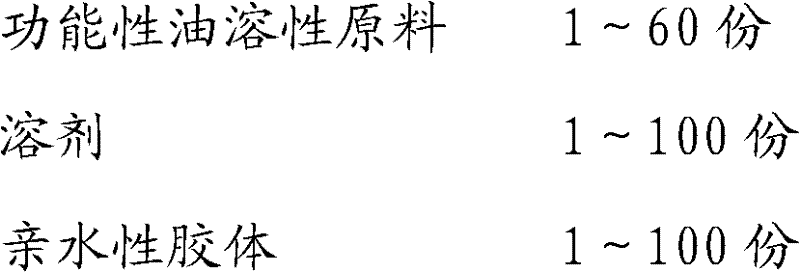

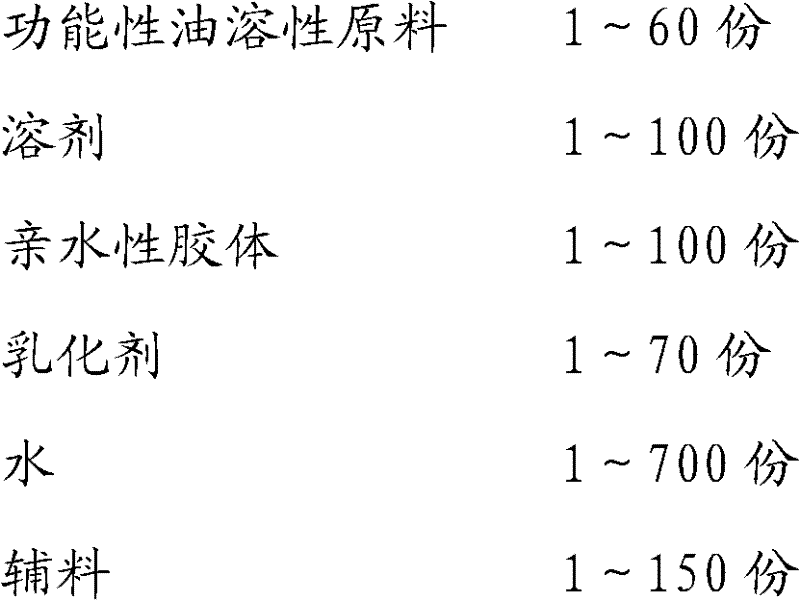

Method used

Image

Examples

Embodiment 1

[0035] 20 parts of gum arabic, add 460 parts of water, heat to dissolve, keep at 65 degrees for 10 minutes, add 40 parts of coenzyme Q10 (purity above 98%), heat to dissolve, add 50 parts of alcohol and polyglycerol fatty acid emulsifier 10 parts and 15 parts of sucrose acetate isobutyrate were vigorously stirred at 80°C for 10 minutes, and then introduced into a homogenizer for homogenization to obtain a nanoemulsified coenzyme Q10 emulsion with a particle size of 100 nm.

Embodiment 2

[0037] 20 parts of gum arabic, add 460 parts of water, heat to dissolve, keep at 65 degrees for 10 minutes, add 40 parts of coenzyme Q10 (purity above 98%), heat to dissolve, add 50 parts of alcohol and polyglycerol fatty acid emulsifier 10 parts and 15 parts of sucrose acetate isobutyrate were vigorously stirred at 80°C for 10 minutes, and then introduced into a homogenizer for homogenization to obtain a nanoemulsified coenzyme Q10 emulsion with a particle size of 100 nm. Then send the emulsion to spray drying under the conditions of inner tower temperature 120°C and outer temperature 90°C to obtain nanoscale coenzyme Q10 powder preparation.

Embodiment 3

[0039] 20 parts of Indian gum, add 400 parts of water, heat to dissolve, keep at 60 degrees for 10 minutes, add 1 part of astaxanthin powder, heat to dissolve, add 30 parts of alcohol and 20 parts of sucrose fatty acid ester, molecular distillation monoglyceride 19 10 parts, 10 parts of sucrose acetate isobutyrate, stirred at 50 degrees for 10 minutes, and then homogenized in a homogenizer at 75 degrees, to obtain a 50-600nm astaxanthin emulsion with a content of 0.5%. It can be used as a raw material for beverages, health care products and cosmetics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com