Preparation method of ZnO-TiO2 composite photocatalyst

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems that no one has reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode 1: This implementation mode prepares ZnO-TiO according to the following steps 2 Preparation method of composite photocatalyst:

[0028] a. Take 1-10ml of titanium salt in absolute ethanol and stir, the titanium salt is tetrabutyl titanate, titanium tetrachloride, tetraethyl titanate or tetrapropyl titanate, etc., absolute ethanol and The volume ratio of titanium salt is between 1 and 4:1, that is, 10ml of butyl titanate can be added to 10ml, 20ml, 30ml, and 40ml of ethanol;

[0029] b. The amount of titanium salt remains unchanged. According to the Zn:Ti molar ratio of 1:1 to 10, respectively weigh the zinc salt in a beaker and dissolve it in 20ml deionized water; after stirring until it is completely dissolved, add ammonia water dropwise until the solution is just from turbid to For clarification, sodium hydroxide is added dropwise to adjust the pH range between 4 and 14, and the zinc salt is any inorganic salt of zinc such as zinc acetate...

specific Embodiment approach 2

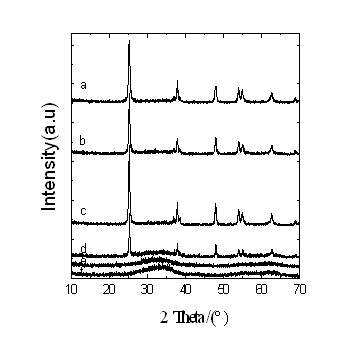

[0033] Specific embodiment two: Measure 10ml of tetrabutyl titanate in 40ml of absolute ethanol and stir; the amount of butyl titanate remains unchanged, and zinc acetate is 1:1, 1:2, 1:1 according to the molar ratio of Zn:Ti 3. 1:5, 1:7 and 1:10 were weighed in a beaker and dissolved in 20ml of deionized water; after stirring until completely dissolved, add ammonia water dropwise until the solution was just from cloudy to clear; slowly add the mixed solution to In a mixed solution of tetrabutyl titanate and absolute ethanol; after continuing to stir for 2 hours, transfer the obtained solution to a 100ml autoclave and heat at a constant temperature of 120°C for 12 hours; naturally cool, centrifuge the obtained product, wash and dry , Grinding to obtain composite photocatalyst powders with different ratios of zinc and titanium.

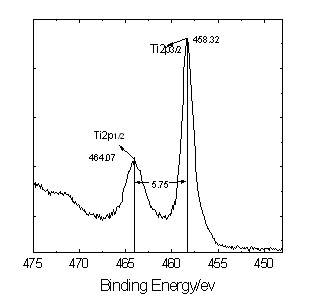

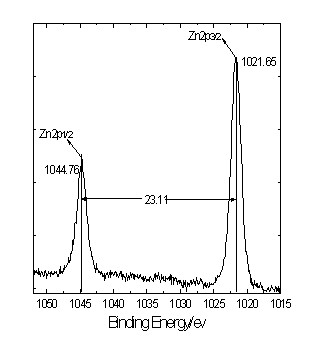

[0034] 1. XPS analysis:

[0035] Depend on figure 1 It can be seen that the peak of O1s in the sample is obviously asymmetrical, which can be consid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com