Method for preparing comby stannous oxide nanometer material

A technology of stannous oxide and nanomaterials, applied in tin oxide, nanotechnology and other directions, to achieve the effect of simple operation, mild and easy control, and industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

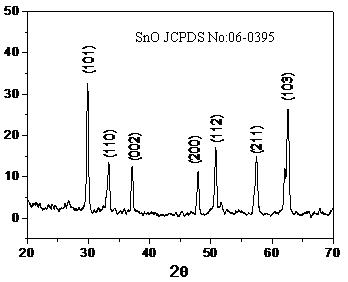

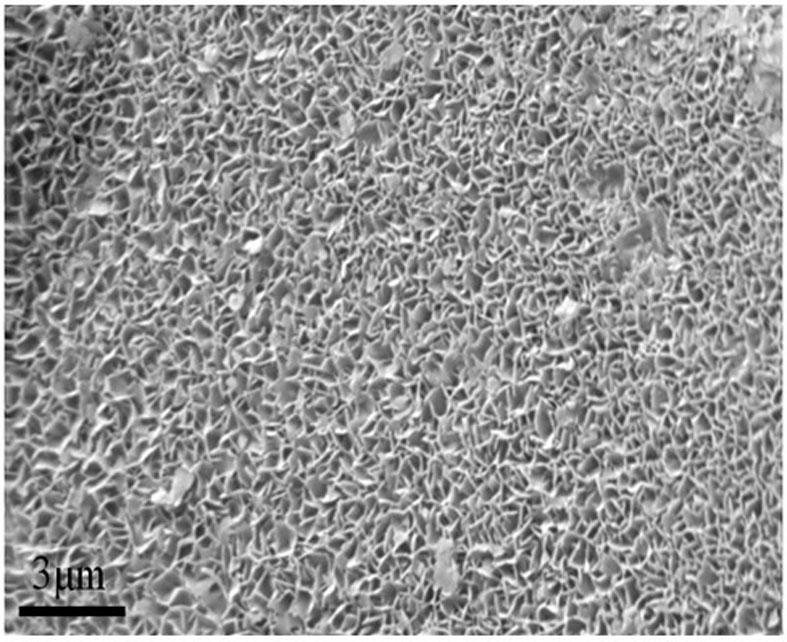

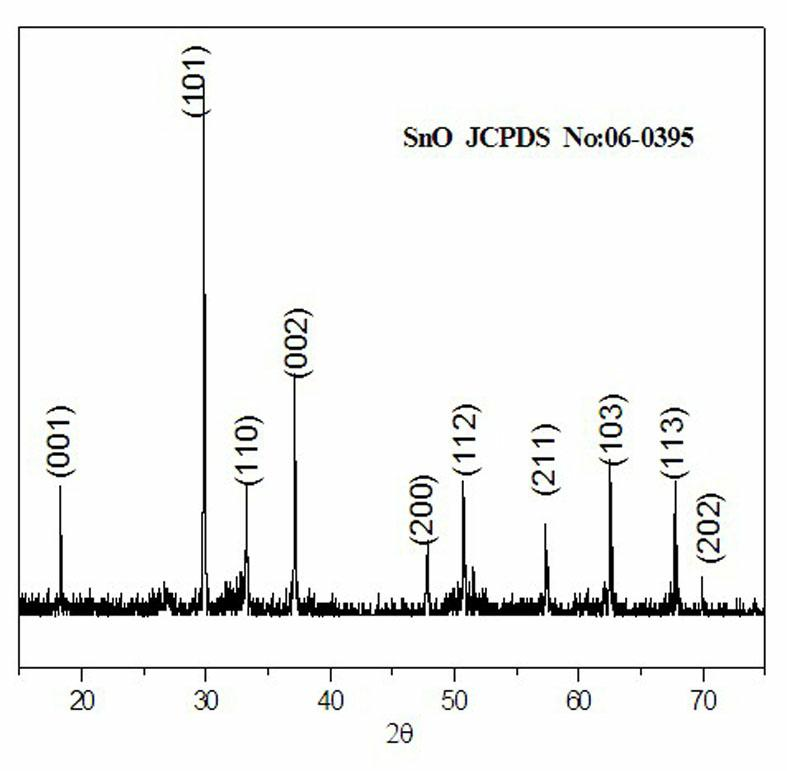

example 1

[0019] 1.822 g of cetyltrimethylammonium bromide was dissolved in 20 ml of deionized water, and stirred until completely dissolved to obtain an aqueous solution of cetyltrimethylammonium bromide. Add 1.128 g of stannous chloride dihydrate into the prepared cetyltrimethylammonium bromide aqueous solution, and stir for 5 minutes to completely dissolve it. Under stirring conditions, 20 ml of sodium hydroxide solution having a molar concentration of 0.75 mol / L was added dropwise to the above solution, and stirring was continued for 10 minutes after the addition was completed to obtain a reaction solution. The molar concentration of stannous chloride dihydrate in the reaction solution is 0.125mol / L, and the molar concentration of sodium hydroxide is 0.375mol / L; In the autoclave, after sealing, heat at 130°C for 15 hours. After the reaction, the reactor was cooled to room temperature with the furnace. After the resulting mixed solution containing the product was centrifuged at a s...

example 2

[0021] 1.458 g of cetyltrimethylammonium bromide was dissolved in 20 ml of deionized water, and stirred until completely dissolved to obtain an aqueous solution of cetyltrimethylammonium bromide. Then 0.902 g of stannous chloride dihydrate was added to the prepared cetyltrimethylammonium bromide aqueous solution, and stirred for 5 minutes to completely dissolve it. Under stirring conditions, 20 ml of sodium hydroxide solution having a molar concentration of 0.400 mol / L was added dropwise to the above solution, and stirring was continued for 10 minutes after the addition was completed to obtain a reaction solution. The molar concentration of stannous chloride dihydrate in the reaction solution is 0.100mol / L, and the molar concentration of sodium hydroxide is 0.200mol / L; In the high-pressure reactor, after sealing, it was treated at 140°C for 14 hours. After the reaction was completed, the reactor was cooled to room temperature with the furnace. After the resulting mixed soluti...

example 3

[0023] Dissolve 2.186 g of cetyltrimethylammonium bromide in 20 ml of deionized water, and stir until completely dissolved to obtain an aqueous solution of cetyltrimethylammonium bromide. Then 1.354 g of stannous chloride dihydrate was added to the prepared cetyltrimethylammonium bromide aqueous solution, and stirred for 5 minutes to completely dissolve it. Under stirring conditions, 20 ml of sodium hydroxide solution having a molar concentration of 1.20 mol / L was added dropwise to the above solution, and stirring was continued for 10 minutes after the addition was completed to obtain a reaction solution. The molar concentration of stannous chloride dihydrate in the reaction solution is 0.150mol / L, and the molar concentration of sodium hydroxide is 0.600mol / L; In the high-pressure reactor, after sealing, it was treated at 160°C for 12 hours. After the reaction, the reactor was cooled to room temperature with the furnace. After the resulting mixed solution containing the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com