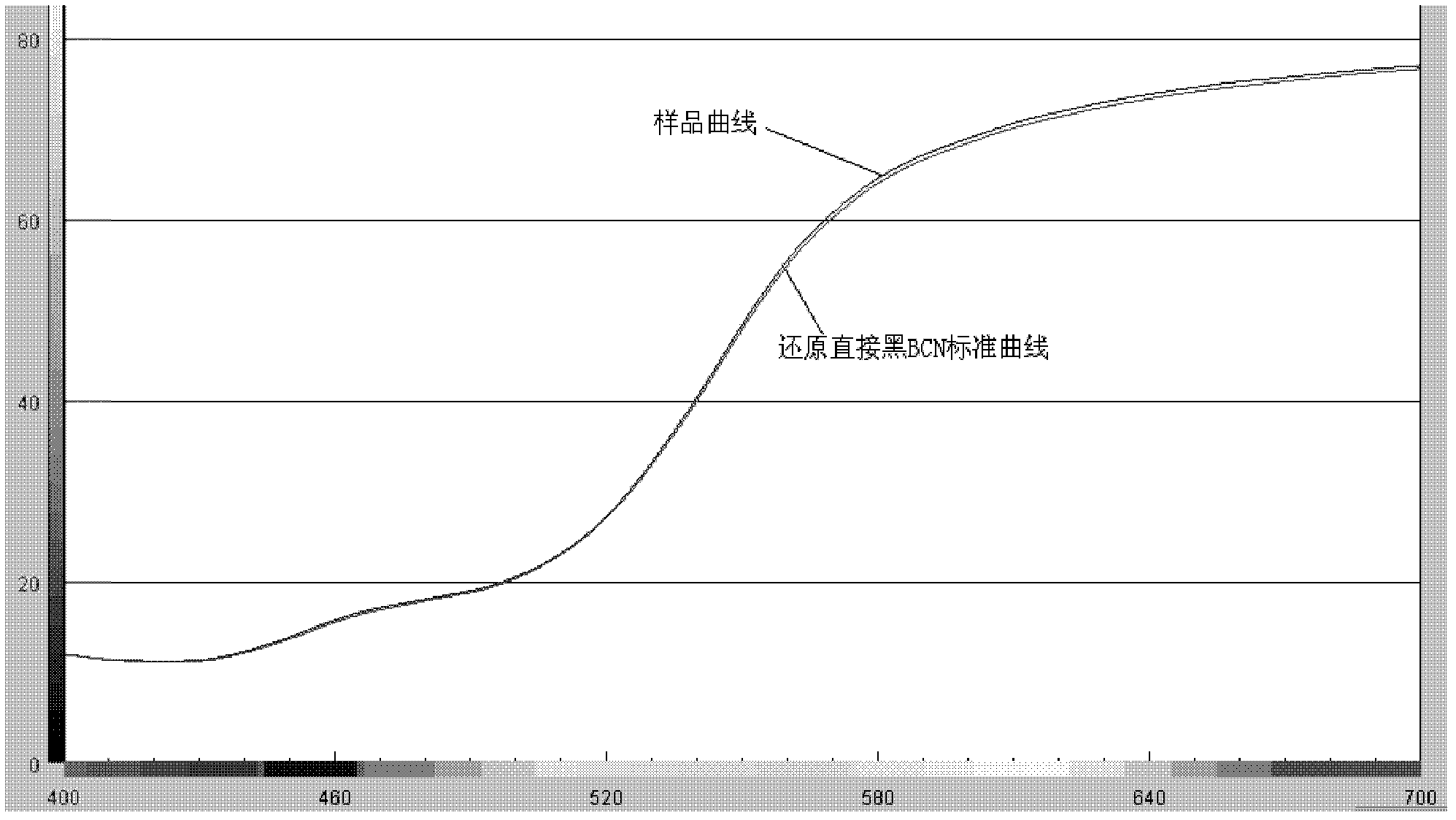

Method for producing reductive direct black BCN raw dye

A direct dye technology, applied in the field of dyes, can solve the problems of unfavorable environmental protection, high toxicity, strong irritation, etc., and achieve the effects of improving dye shade and application performance, good economic and social benefits, and good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

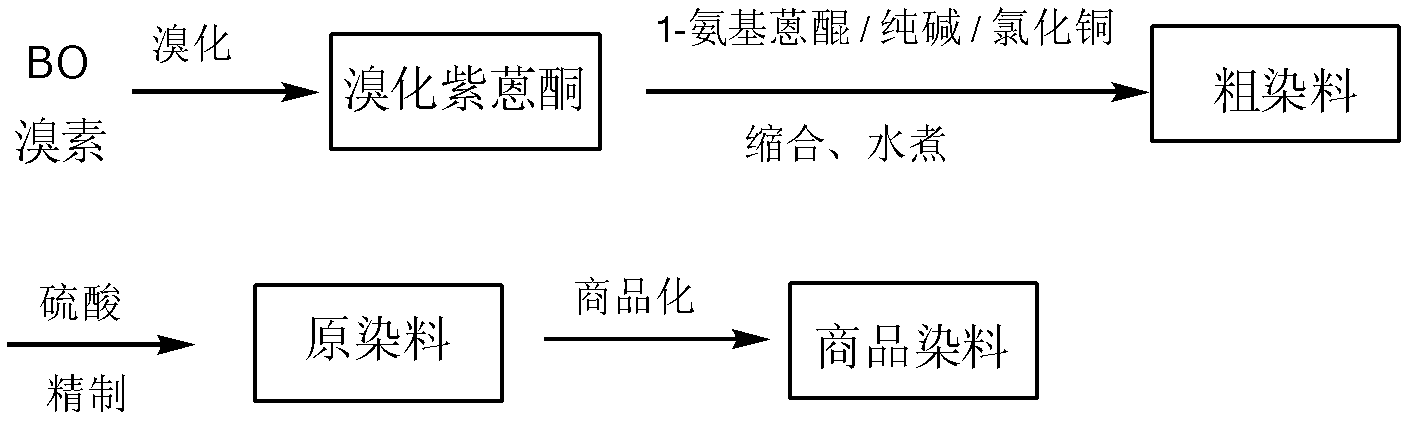

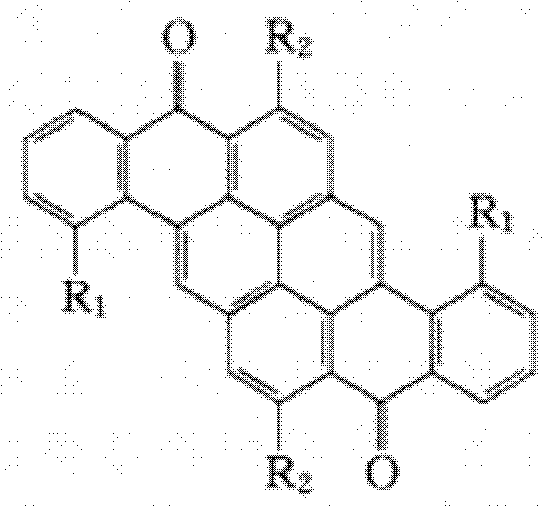

Method used

Image

Examples

Embodiment 1

[0031] Add 210g of water into a 250mL three-necked flask (installed with a thermometer and a reflux condenser, which is filled with frozen brine, with an exhaust pipe and an exhaust gas absorption device attached to remove the generated HBr and other acidic gases), start stirring, and add reduced dark blue BO 15g, beat for 2 hours, add 4.5g of sodium chlorate, 10.5g of bromine, heat up to 70-100°C, and stir at 70-100°C for 5 hours. Recover bromine by distillation, lower the temperature to 50°C, filter, wash until neutral, and dry to obtain violinanthrone bromide. The yield is 130% based on violinthone. The bromine content of the product was detected to be 25.89% (26.1% in theory). The product is dyed cotton in red light navy blue.

Embodiment 2

[0033] Add 350g of water to a 500mL three-necked flask (installed with a thermometer, a reflux condenser, and refrigerated brine into the condenser, with an exhaust pipe and an exhaust gas absorption device attached to remove the generated HBr and other acidic gases), start stirring, and add 25g of BO The filter cake was beaten for 2 hours, 7.5g of sodium chlorate and 17.5g of bromine were added, the temperature was raised to 70-100°C, and the mixture was stirred at 70-100°C for 6 hours. Bromine was recovered by distillation, and the temperature was lowered to 50°C. Filtrate, wash until neutral, and dry to obtain violinanthrone bromide, with a yield of 132% based on violinthrone. The bromine content of the product was detected to be 26.32% (theoretical 26.1%). The product is dyed cotton in red light navy blue.

Embodiment 3

[0035] Using solid phase reaction, add 15g of violinanthrone bromide obtained in Example 1, 13g of 1-aminoanthraquinone, 8g of soda ash, 1g of copper oxide, mix and stir for half an hour, raise the temperature to 120-130°C, dehydrate for 1 hour, continue Raise the temperature to 230-260°C and keep it warm for 5 hours. The temperature was lowered to below 60° C., and the material was discharged to obtain 38 g of crude dye.

[0036] The obtained crude product was added to 600 mL of water, boiled for 1 hour, cooled, filtered, washed until neutral, and dried to obtain 28 g of dry product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com