Polyvinylidene fluoride resin composition, film, back sheet, and solar cell module

A technology of polyvinylidene fluoride and resin composition, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as film defects and poor dispersion, and achieve the effects of less defects, improved dispersion, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

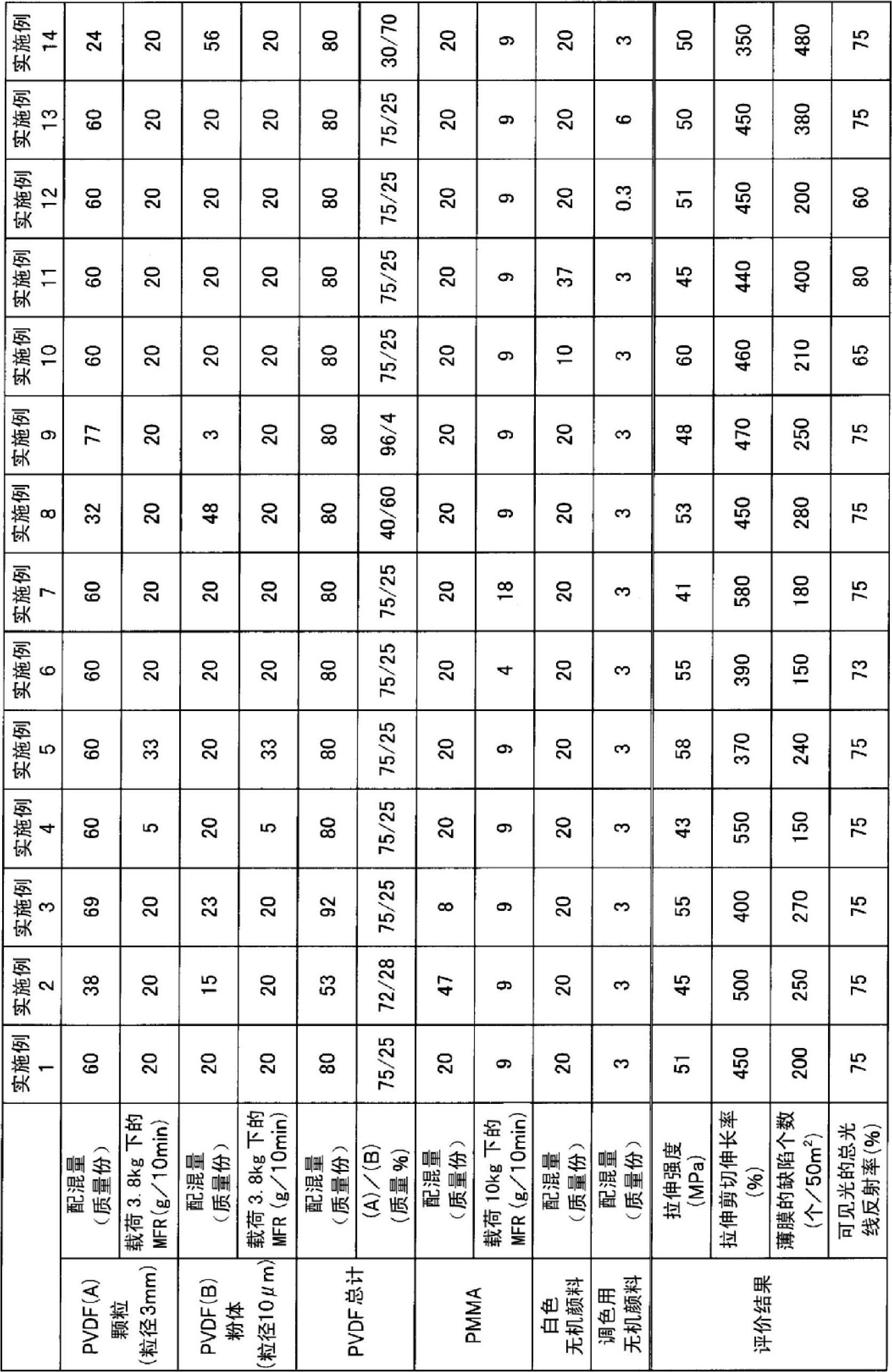

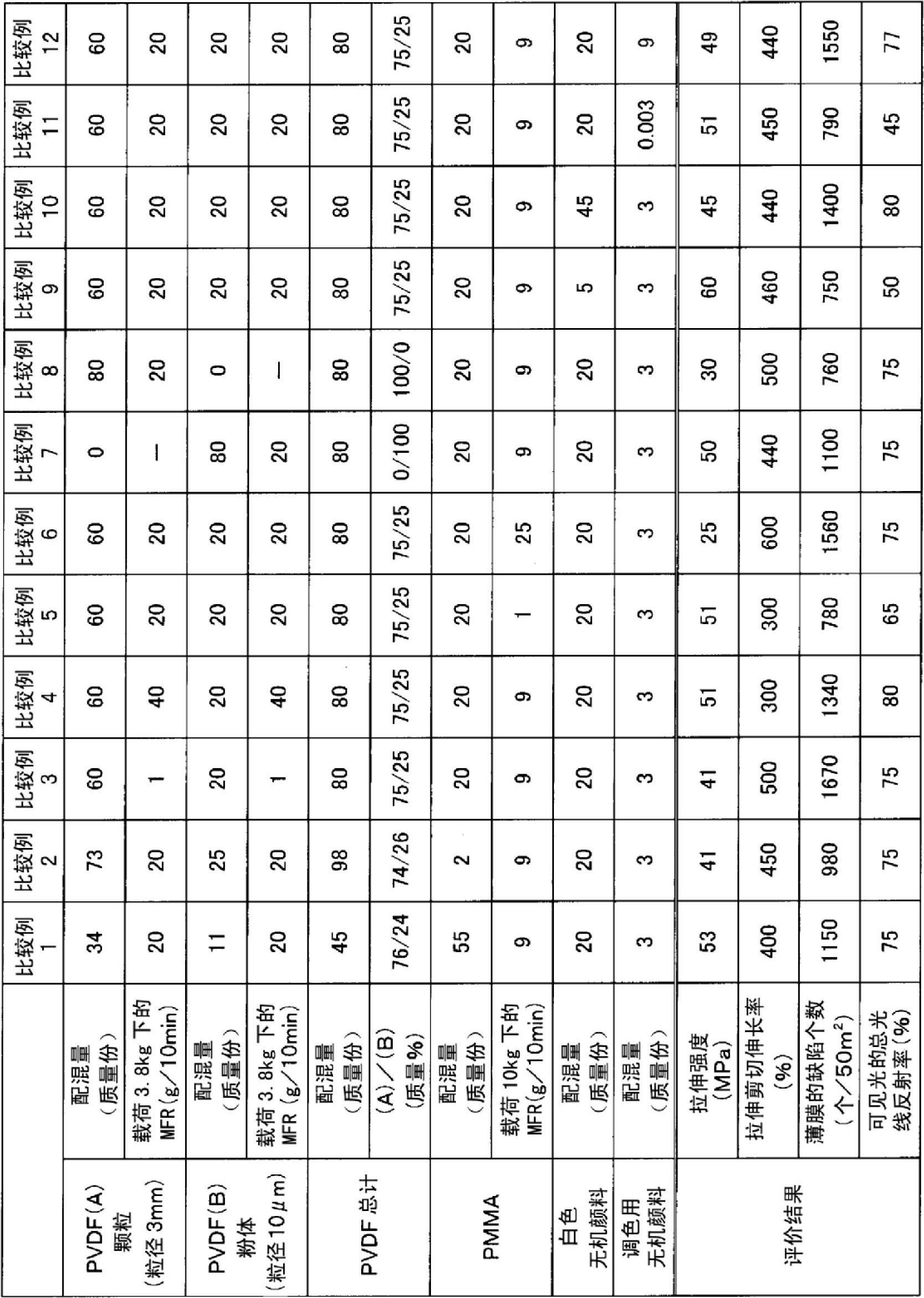

[0029] First, a polyvinylidene fluoride-based resin composition (hereinafter also simply referred to as a resin composition) according to a first embodiment of the present invention will be described. The resin composition according to the present embodiment contains at least a white inorganic pigment and an inorganic pigment for color tone in a resin component composed of two types of PVDF and PMMA having different forms.

[0030] [PVDF: total 50~95% by mass in the resin component]

[0031] PVDF is excellent in weather resistance and heat resistance, and is the main component of the resin composition of this embodiment. However, when both of the two types of PVDF to be compounded are PVDFs with an MFR of less than 3 g / 10 min, the dispersion of the white inorganic pigment and the inorganic pigment for toning in PVDF is reduced, and defects are likely to occur when forming a thin film. On the other hand, when two kinds of PVDFs are used as PVDFs with an MFR exceeding 35 g / 10 m...

no. 2 Embodiment approach )

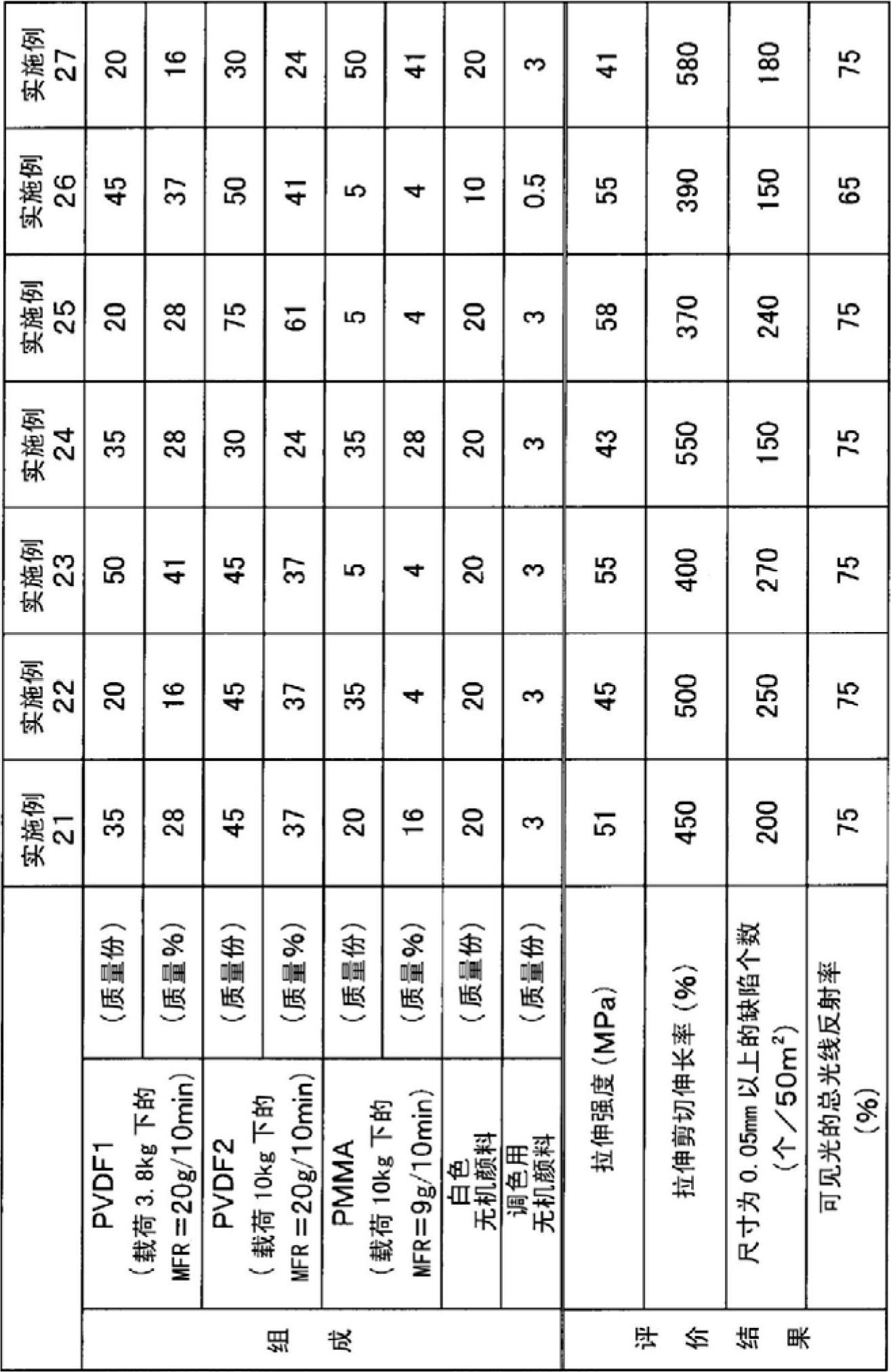

[0068] Hereinafter, a polyvinylidene fluoride-based resin composition according to a second embodiment of the present invention will be described. The resin composition of the present embodiment is the same as the resin composition of the first embodiment described above except that two types of PVDF having different melt flow properties are blended.

[0069] [PVDF: total 50~95% by mass in the resin component]

[0070] In the resin composition of the present embodiment, two types of PVDF (PVDF1 and PVDF2) having different melt flow characteristics are used. These resins may be in the form of pellets or in the form of powder, and these two forms of resins may be mixed and used. In addition, the melt flow characteristic of each raw material resin component shown below is the value measured according to the measuring method of MFR (Melt Flow Rate) stipulated in the A method of JISK7210 unless otherwise stated.

[0071] One of the two types of PVDF (PVDF1) used was PVDF whose MFR ...

Embodiment 1)

[0081] (1) Preparation of inorganic pigments for toning

[0082] 0.8 kg of black inorganic pigment powder formed from oxide solid solution of chromium, manganese and copper, 1.6 kg of brown pigment powder formed of oxide solid solution of zinc, iron, nickel and aluminum, and blue pigment powder formed of cobalt aluminate 0.6 kg was mixed in a dry mixer to produce an inorganic pigment for coloring. Then, 0.03 kg of n-hexyltrimethoxysilane was added to a mixed solution of 0.3 kg of 0.1 mass % acetic acid aqueous solution and 0.3 kg of ethanol to prepare a silane coupling agent solution. Then, the inorganic pigment for color adjustment is added into the mixer, and the silane coupling agent solution is added dropwise while stirring, and mixed. After mixing, take it out, dry it with a drier, and then crush it into powder. The average particle size (median particle size) of the obtained inorganic pigment for toning was 0.3 μm.

[0083] (2) Resin composition

[0084] As the resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com