Processing method for carrying out oil stain type high-pressure cooking on engraulis japonius

A processing method and oil-soaked technology, which is applied in the field of clove fish oil-soaked high-pressure cooking, can solve the problems of high production and enterprise losses, and achieve the effect of less nutritional loss, good product quality and attractive flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

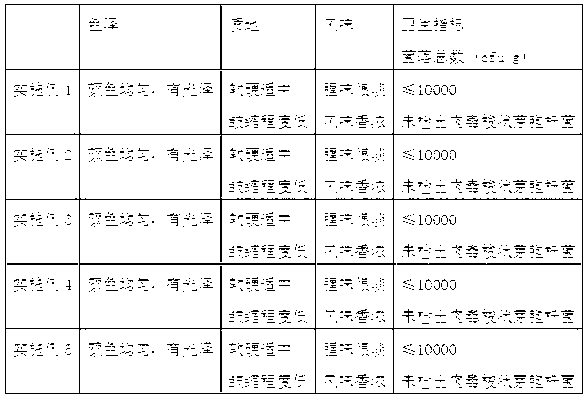

Examples

Embodiment 1

[0026] (1) Select raw materials of clove fish, wash and drain;

[0027] (2) Salting: use 10% salt water for salting, the mass ratio of salt water to fish is 1:1.5, and the salting time is 2 hours. After salting, wash with water and drain;

[0028] (3) Vacuum dipping and seasoning: Pour the salted clove fish into the seasoning liquid, mix the clove fish and seasoning liquid evenly, and use vacuum dipping and seasoning. The vacuum degree is 0.06 MPa, and the soaking time is 30 minutes. The mass ratio of the seasoning liquid to clove fish is 2:1, stir once every 10 minutes, the seasoning liquid is 4g of monosodium glutamate, 20g of sugar, and 20g of cooking wine per 1 L of water;

[0029] (4) High-pressure curing: Steam clove fish in a high-pressure sterilizer, heat to remove cold air, heat to a pressure of 0.4Mpa, and when the temperature is 50°C, keep it warm for 10 minutes, then raise the temperature, control the temperature at 100°C, steam for 15 minutes, and stop heating ca...

Embodiment 2

[0034] (1) Select raw materials of clove fish, wash and drain;

[0035] (2) Salting: use 10% salt water for salting, the mass ratio of salt water to fish is 1:1.5, and the salting time is 2 hours. After salting, wash with water and drain;

[0036] (3) Vacuum impregnation seasoning: Pour the clove fish into the seasoning liquid, mix the clove fish with the seasoning liquid evenly, and use vacuum impregnation for seasoning. The vacuum degree is 0.065 MPa, and the soaking time is 30 minutes. The mass ratio of the seasoning liquid to clove fish is 2:1, stir once every 10 minutes, the seasoning liquid is 5g of monosodium glutamate, 20g of sugar, and 20g of cooking wine per 1 L of water;

[0037] (4) High-pressure curing: steam clove fish in a high-pressure sterilizer, heat to remove cold air, heat to a pressure of 0.5Mpa, and when the temperature is 50°C, keep it warm for 10 minutes, then raise the temperature, control the temperature at 105°C, steam for 15 minutes, and stop Just ...

Embodiment 3

[0042] (1) Select raw materials of clove fish, wash and drain;

[0043] (2) Salting: Use salt water with a mass percentage concentration of 11% for salting, the mass ratio of salt water to fish is 1:2, and the salting time is 2.5 hours. After salting, wash with water and drain

[0044] (3) Vacuum impregnation seasoning: Pour the clove fish into the seasoning liquid, mix the clove fish with the seasoning liquid evenly, and use vacuum impregnation for seasoning. The vacuum degree is 0.065 MPa, and the soaking time is 30 minutes. The mass ratio of the seasoning liquid to clove fish is 2:1, stir once every 10 minutes, the seasoning liquid is 5g of monosodium glutamate, 25g of sugar, and 25g of cooking wine per 1 L of water;

[0045] (4) High-pressure curing: steam clove fish in a high-pressure sterilizer, heat to remove cold air, heat to a pressure of 0.5Mpa, and when the temperature is 60°C, keep it warm for 10 minutes, then raise the temperature, control the temperature at 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com