Anti-impact and wear-resistant mortar

A technology of wear-resistant sand and Portland cement, which is applied in the field of mortar of hydropower engineering materials technology, can solve the problems of poor crack resistance, easy cracks, and low mortar strength, and achieve low elastic modulus and stable strength growth , the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

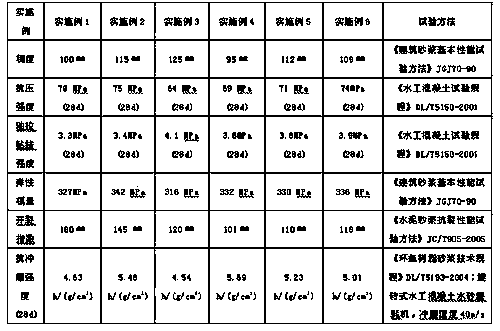

Examples

Embodiment 1

[0065] Embodiment 1: The components and parts by weight of the anti-impact and wear-resistant mortar in this embodiment are: 47 parts of low-heat Portland cement, 50 parts of sand in basalt, 1.5 parts of redispersible latex powder, powdery polycarboxylate water-reducing 0.2 parts of antifoaming agent, 0.3 parts of polyether defoamer, nano-SiO 2 0.4 parts, nano CaCO 3 0.6 parts.

[0066] Preparation method: Weigh each component according to the above-mentioned parts by weight, mix in a mixer, and form a product after mixing evenly;

[0067] How to use: Add appropriate amount of water to the anti-scour and wear-resistant mortar to make the consistency meet the requirements of use; the conventional construction method of anti-scouring and wear-resistant materials is used for construction, and it is mainly used for repairing hydropower projects.

Embodiment 2

[0068] Embodiment 2: The components and parts by weight of the anti-impact and wear-resistant mortar in this embodiment are: 44 parts of low-heat Portland cement, 44 parts of sand in basalt, 1.0 part of redispersible latex powder, and powdery polycarboxylate water-reducing 0.10 parts of antifoaming agent, 0.20 parts of polyether defoamer, nano-SiO 2 0.7 parts, 5 parts of fly ash, 5 parts of slag.

[0069] The preparation method and usage method are the same as in Example 1.

Embodiment 3

[0070] Embodiment 3: The components and parts by weight of the anti-impact and wear-resistant mortar of this embodiment are: 40 parts of medium-heat Portland cement, 42 parts of quartz medium sand, 1.5 parts of redispersible latex powder, and powdery polycarboxylate 0.15 parts of water agent, 0.25 parts of polyether defoamer, nano-SiO 2 0.5 parts, 5 parts of fly ash, 10 parts of slag, 0.6 parts of sodium sulfate.

[0071] The preparation method and usage method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydration enthalpy | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com