Method for preparing polyurethane/polyacrylate core-shell emulsion

A polyacrylate, core-shell emulsion technology, applied in the direction of graft polymer adhesive, adhesive type, fiber treatment, etc. Water resistance can be designed, rheological properties can be designed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

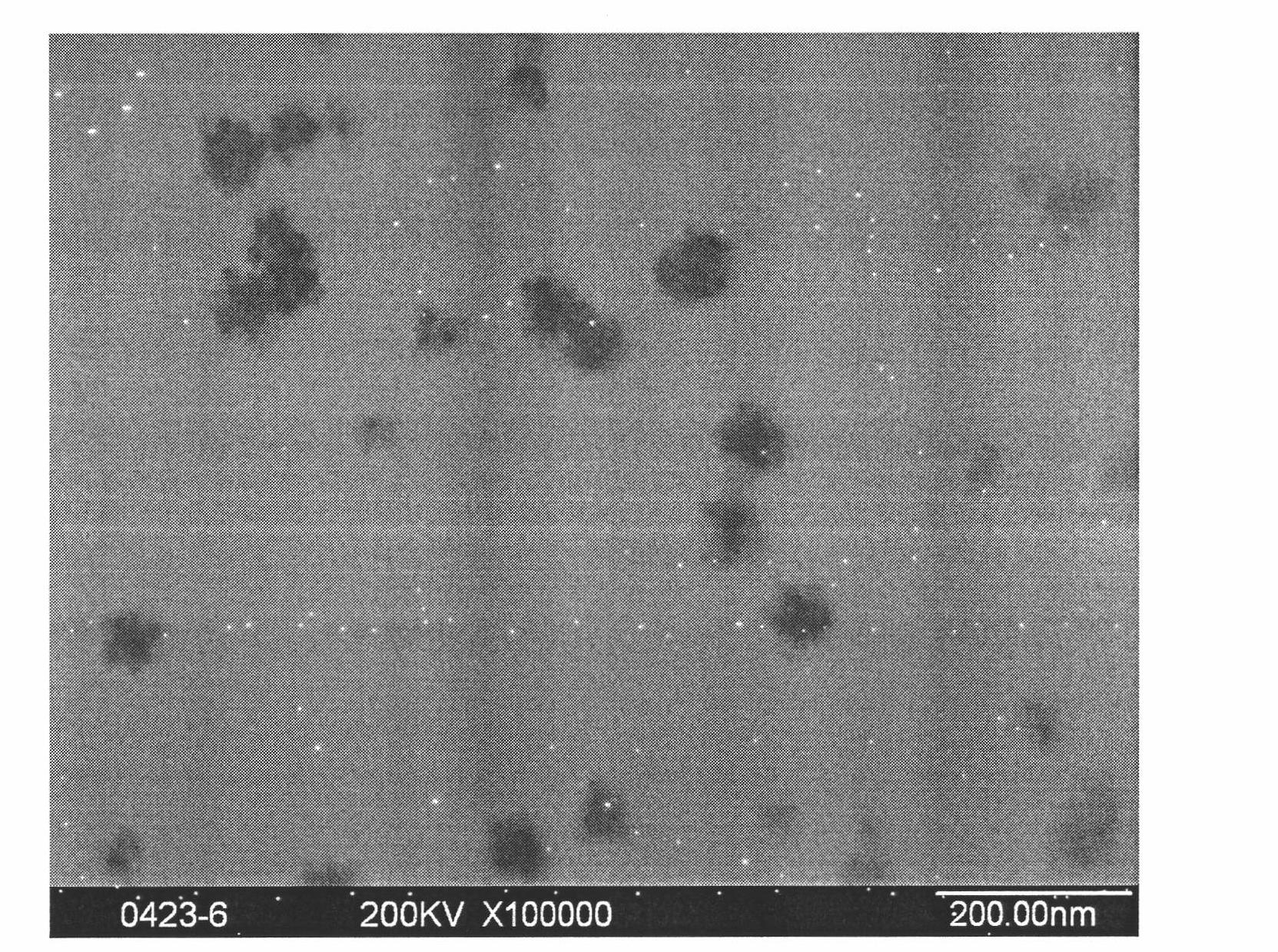

Image

Examples

Embodiment 1

[0037] 1) Synthesis of polyester polyols containing sulfonate groups

[0038] Add 304.78g of 1,6-hexanediol and 46.22g of isophthalic acid-5-sodium sulfonate (5-SSIPA) into the 2 In the four-necked flask with conduit, thermometer, mechanical stirring and reflux condenser, heat up to 210°C and reflux for 30 minutes, then cool down to 70°C, add 252.96g of adipic acid and 3.01g of dibutyltin dilaurate, change the distillation device at 160°C After heating for 30 minutes, heat at 180° C. for 30 minutes, react at 210° C. for 1 hour, and finally distill under reduced pressure at 10 mmHg to stop the reaction. The material is discharged and stored dry. The product obtained was a clear liquid at high temperature and a white waxy solid at room temperature.

[0039] According to HGT 2708-1995, the acid value of polyester polyol products containing sulfonate groups is 0.79mgKOH / g;

[0040] According to HGT 2709-1995, the hydroxyl value of the polyester polyol product containing sulfonat...

Embodiment 2

[0046] 1) the synthesis of polyester polyol containing sulfonate group is the same as in Example 1

[0047] 2) the preparation of aqueous polyurethane emulsion is the same as embodiment 1

[0048] 3) Preparation of polyurethane / polyacrylate core-shell emulsion

[0049] Add 78.95g of the WPU emulsion prepared in step 2) to a 500mL four-neck flask with nitrogen, a thermometer, and mechanical stirring, and raise the temperature to 80°C, then add 20.20g of MMA, 25.85g of BA, and 0.92g of AA dropwise to it with a constant pressure funnel. The aqueous solution of monomer and KPS (0.28g dissolved in 30g deionized water) was dripped within 2-3 hours, and kept at 80°C for 1 hour. After cooling, it was filtered and discharged to obtain a light blue emulsion: PUA-2.

Embodiment 3

[0051] 1) the synthesis of polyester polyol containing sulfonate group is the same as in Example 1

[0052] 2) Preparation of water-based polyurethane emulsion

[0053] The product of 65.91g step 1) is added into the 2 In the four-necked flask with catheter, thermometer, mechanical stirring and reflux condenser, raise the temperature to 120°C and wait for it to melt, then distill under reduced pressure at 10mmHg for 0.5h to remove water, then cool down to 80°C, add 0.37g of dibutyltin dilaurate, and stir After uniformity, add 10.89gIPDI, react at 60°C for 3h, add 13.16gMMA and 16.84gBA monomer to reduce the viscosity as the viscosity of the polyurethane prepolymer increases, and then add the polyurethane prepolymer into the aqueous solution of ethylenediamine (0.46 g ethylenediamine was dissolved in 288.58g deionized water) and dispersed for 2h to obtain a white emulsion.

[0054] 3) Preparation of polyurethane / polyacrylate core-shell emulsion

[0055] Add 132g of the WPU e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com