Recovery and utilization method of highly toxic medium hydrothion waste gas generated in polyphenylene sulfide production

A polyphenylene sulfide and exhaust gas recovery technology, which is applied in the field of polymer material synthesis, can solve the problems of hydrogen sulfide toxicity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

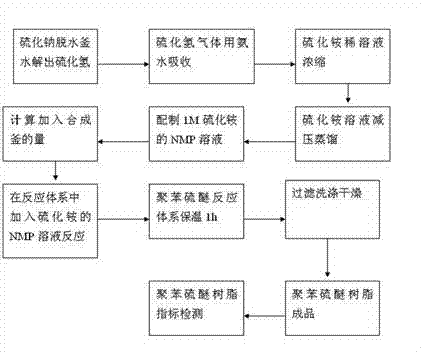

Method used

Image

Examples

Embodiment 1

[0018] will contain H 2 S passes into the 500-liter ammonia water absorption tank to react, and the exhaust gas is input from the lower end, adopting the bubbling method, H 2 S to (NH 4 ) 2 S, under the protection of nitrogen, so as to obtain a dilute ammonium sulfide solution, and then input the heat released by the synthesis of polyphenylene sulfide resin (water vapor at 100-150°C) into the ammonium sulfide solution tank, which is With stirring and jacket, it releases heat by controlling the synthesis of polyphenylene sulfide resin input, so that the temperature of the dilute ammonium sulfide solution is gradually raised to 100 ° C, and a certain amount of water vapor is evaporated, and the water vapor is cooled and waited. Use, while the ammonium sulfide solution is concentrated into a solution with a concentration of 16%wt, then the ammonium sulfide solution is distilled under reduced pressure, and the water that is distilled is reclaimed to obtain a solution containing ...

Embodiment 2

[0020] will contain H 2 S passes into the 500-liter ammonia water absorption tank to react, and the exhaust gas is input from the lower end, adopting the bubbling method, H 2 S to (NH 4 ) 2 S, under the protection of nitrogen, so as to obtain a dilute ammonium sulfide solution, and then input the heat released by the synthesis of polyphenylene sulfide resin (water vapor at 100-150°C) into the ammonium sulfide solution tank, which is With stirring and jacket, it releases heat by controlling the synthesis of polyphenylene sulfide resin input, so that the temperature of the dilute ammonium sulfide solution is gradually raised to 100 ° C, and a certain amount of water vapor is evaporated, and the water vapor is cooled and waited. At the same time, the ammonium sulfide solution is concentrated into a solution with a concentration of 20%wt, and then the ammonium sulfide solution is distilled under reduced pressure to reclaim the distilled water to obtain a solution containing 80%w...

Embodiment 3

[0022] will contain H 2 S passes into the 500-liter ammonia water absorption tank to react, and the exhaust gas is input from the lower end, adopting the bubbling method, H 2 S to (NH 4 ) 2 S, under the protection of nitrogen, so as to obtain a dilute ammonium sulfide solution, and then input the heat released by the synthesis of polyphenylene sulfide resin (water vapor at 100-150°C) into the ammonium sulfide solution tank, which is With stirring and jacket, it releases heat by controlling the synthesis of polyphenylene sulfide resin input, so that the temperature of the dilute ammonium sulfide solution is gradually raised to 100 ° C, and a certain amount of water vapor is evaporated, and the water vapor is cooled and waited. Use, while the ammonium sulfide solution is concentrated into a solution with a concentration of 18%wt, then the ammonium sulfide solution is distilled under reduced pressure, and the water that is distilled is reclaimed to obtain a solution containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com