Polar-region and deep-sea habitat actinomycete having strong killing effect for various pests and metabolites thereof

A technology of metabolites and actinomycetes, applied in microorganisms, biochemical equipment and methods, bacteria, etc., to achieve the effect of good pesticide development potential, strong insecticidal activity and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Streptomyces nitrosporus CQT14-24 bacterial strain is obtained, biological characteristic and identification

[0017] T14-24 Streptomyces nitrosporeus was isolated from the deep-sea sediments of the Chukchi Sea in the Arctic in August 2002. After being isolated, it was screened out by a conventional insecticidal model (Xiaocai's stomach toxicity model), and its biological and molecular biological characteristics Studies were conducted and strains were identified based on the above characteristics

[0018] Morphological characteristics: cultured in the modified Gaoshi No. 1 medium at 19°C for 7 days, and observed the morphology of the bacteria with an optical microscope.

[0019] Culture characteristics: After culturing in the above medium for 7 days, observe the colony formation and color.

[0020] Physiological and biochemical characteristics: refer to the "Handbook of Actinomycetes Identification" and use conventional methods.

[0021] Experimental res...

Embodiment 2

[0027] Embodiment 2: artificial cultivation and fermentation of Streptomyces nitrosporus CQT14-24 bacterial strain

[0028] After optimizing the growth conditions of the Streptomyces nitrosporus CQT14-24 bacterial strain by conventional methods, the most suitable medium was selected to be composed of the following: 12 g of soluble starch, 6 ml of corn infusion juice, 300 ml of sea mud infusion juice, KNO 3 1g, K 2 HPO 4 0.5g, MgSO 4 0.5g, NaCl 10g, KCl 0.03g, MgCl 2 0.23g, 700ml of water; the culture conditions of Streptomyces nitrosporusCQT14-24 strain are as follows: in a shaker flask or fermenter, the temperature is controlled between 19-23°C; the speed is controlled at 140-150rpm; , gas-liquid ratio and tank pressure can be controlled at 1:1 and 0.05MPa, pH 7.0-7.5, respectively.

[0029] During the cultivation process, defoamers such as soybean oil or foam enemy can be used for defoaming. The culture time is controlled between 14 and 15 days. At this time, the C...

Embodiment 3

[0030] Example 3: Fermentation Extraction and Metabolite Separation and Purification after Artificial Culture of Streptomyces nitrosporeus CQT14-24 Strain

[0031] The above fermented product is separated into supernatant and mycelium by conventional separation means such as centrifugation or filtration.

[0032] (1) Add acetone (volume 1:2) to extract the mycelium after breaking the wall, evaporate the extract to dryness, and obtain the crude acetone extract of the mycelium (abbreviation: acetone extract)

[0033] (2) The mycelium extract bacterial liquid is concentrated 5 times by conventional vacuum evaporation method, and it is a fermentation concentrated liquid (abbreviation: concentrated liquid)

[0034] (3) Add ethyl acetate (volume 1:1) to the fermentation concentrate for extraction, evaporate the extract to dryness, and obtain the ethyl acetate extract of the bacterial liquid (abbreviation: bacterial liquid extract)

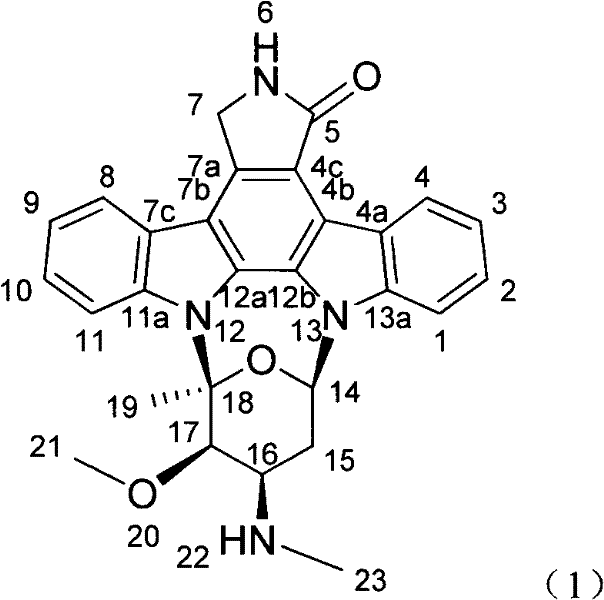

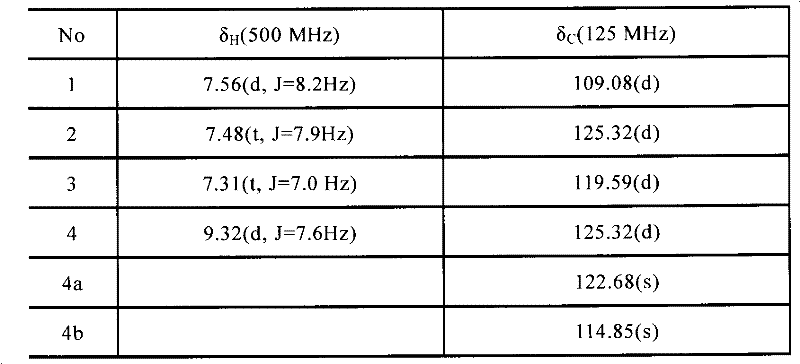

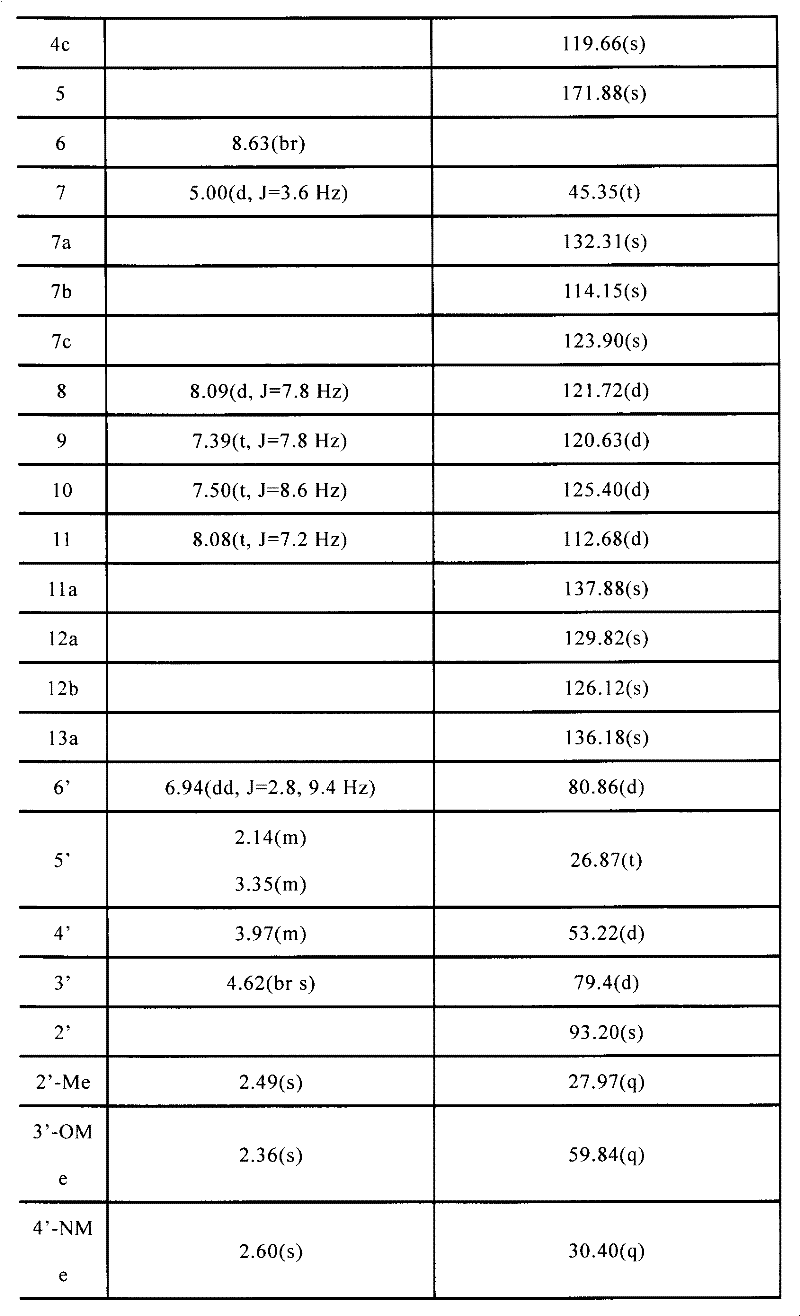

[0035] The above crude extract was dissolved in 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com