Preparation method of active antibacterial composite coating on surface of titanium and titanium alloy medical instrument

A technology for medical devices and composite coatings, which is applied in the direction of surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., to achieve the effects of large content, good repeatability, and improved antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

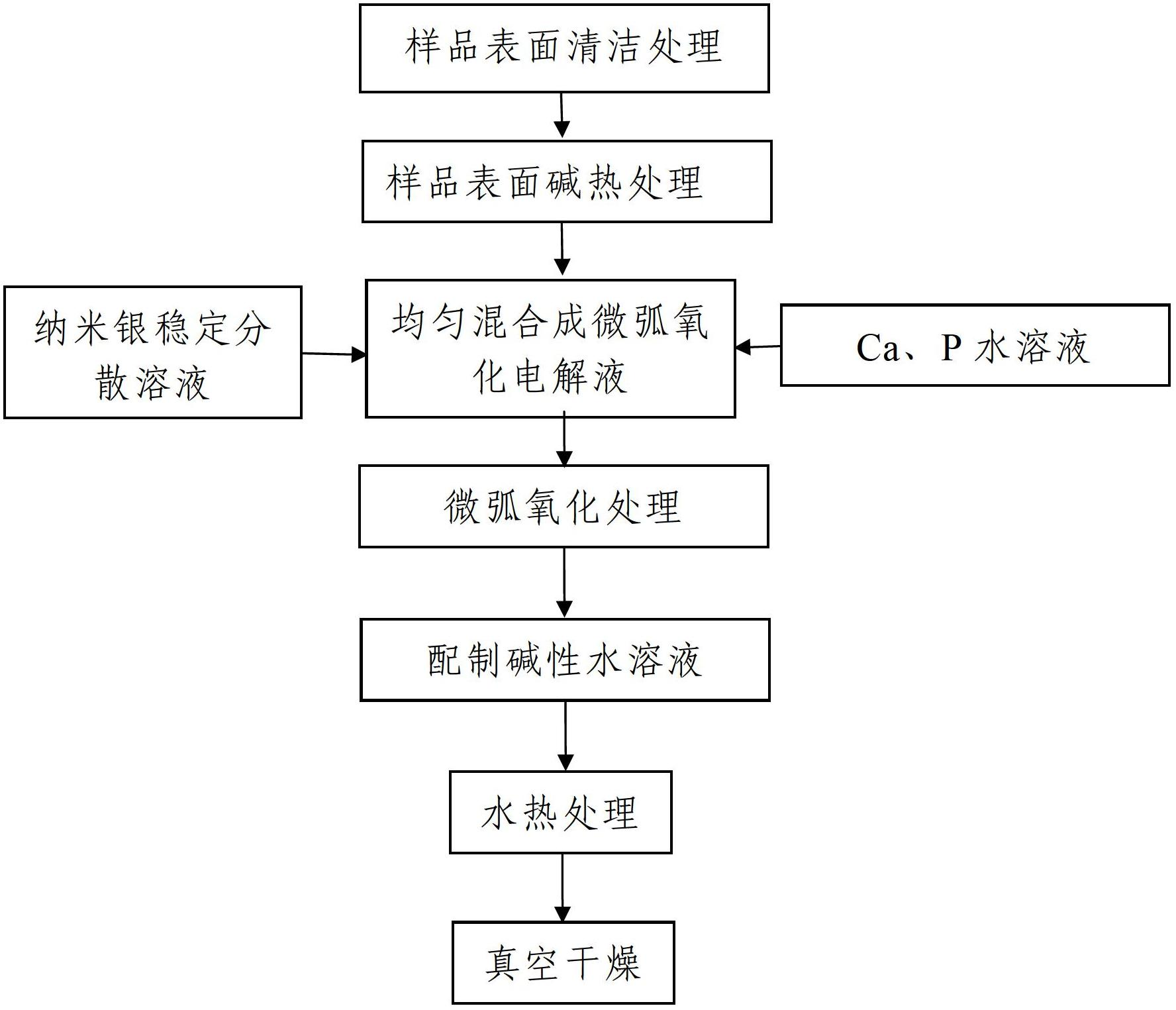

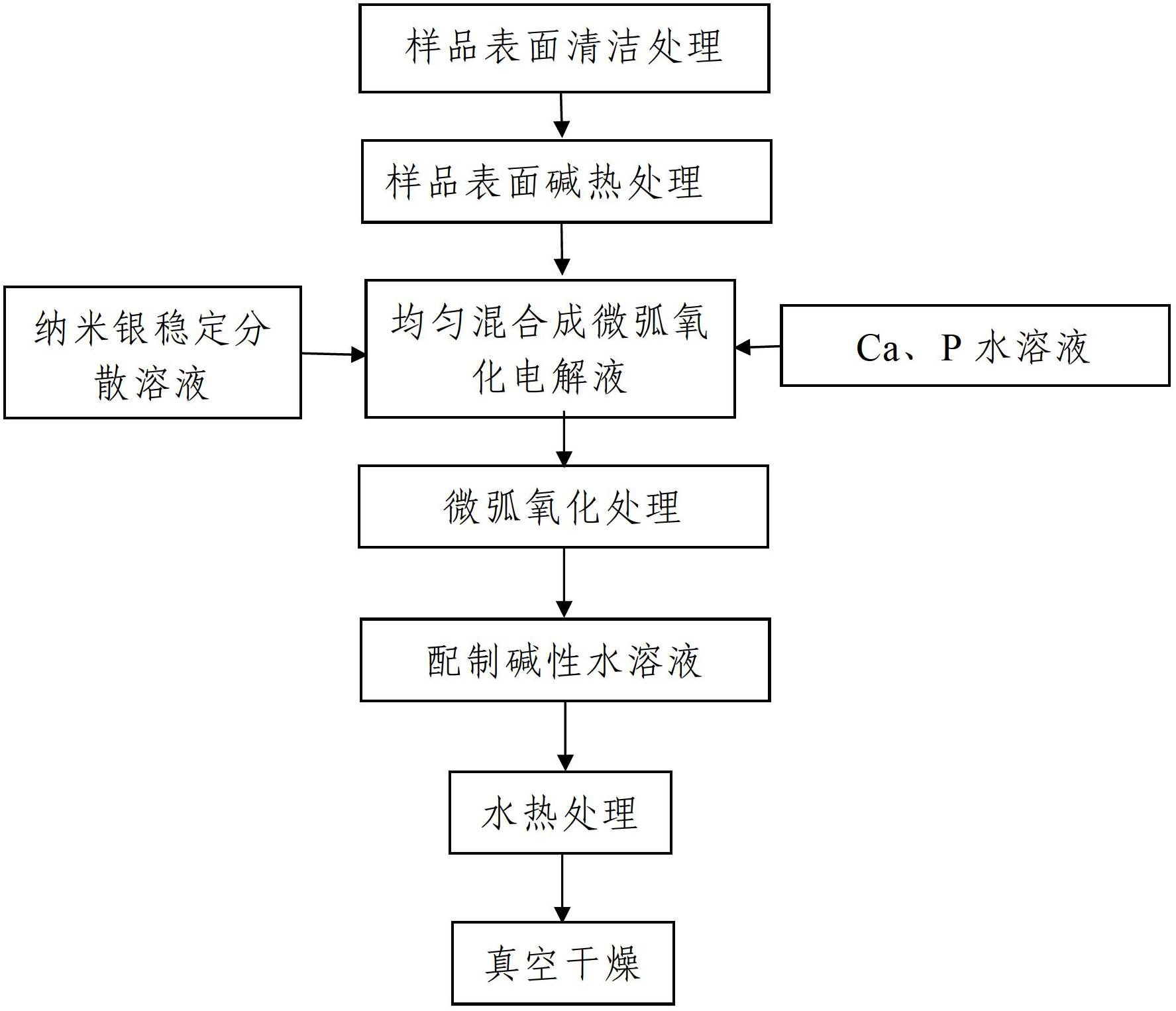

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Surface pretreatment of pure titanium medical devices to be treated:

[0036] 101. Surface cleaning treatment: ultrasonically clean the pure titanium medical device to be treated with distilled water, dilute hydrochloric acid solution, acetone (analytical grade) and absolute ethanol (analytical grade) in sequence, and the time for each ultrasonic cleaning is 20 minutes. The pure titanium medical device after ultrasonic cleaning is dried at a temperature of 40°C; the mass concentration of the dilute hydrochloric acid solution is 2%;

[0037]102. Alkali heat treatment: completely immerse the pure titanium medical device after drying in 101 in the NaOH solution with a concentration of 5mol / L, heat the NaOH solution to 50°C and keep it warm for 24h, take out the pure titanium medical device after cooling and use deionized clean with water;

[0038] Step 2, preparation of antibacterial active composite coating:

[0039] 201. Prepare a stable dispersed aqueous solut...

Embodiment 2

[0049] Step 1. Surface pretreatment of medical Ti6Al4V (ELI) titanium alloy medical devices to be treated:

[0050] 101. Surface cleaning treatment: Ultrasonic cleaning of Ti6Al4V (ELI) titanium alloy medical instruments to be treated with distilled water, dilute hydrochloric acid solution, acetone (analytical pure) and absolute ethanol (analytical pure) in sequence, and the time for each ultrasonic cleaning All for 30 minutes, drying the medical Ti6Al4V (ELI) titanium alloy medical device after ultrasonic cleaning at a temperature of 80°C; the mass concentration of the dilute hydrochloric acid solution is 3%;

[0051] 102. Alkali heat treatment: completely immerse the medical Ti6Al4V (ELI) titanium alloy medical device dried in 101 in the NaOH solution with a concentration of 7mol / L, heat the NaOH solution to 50°C and keep it warm for 30h, and take out the medical Ti6Al4V after cooling (ELI) titanium alloy medical devices and cleaned with deionized water;

[0052] Step 2, pr...

Embodiment 3

[0063] Step 1. Surface pretreatment of medical Ti6Al7Nb titanium alloy medical devices to be treated:

[0064] 101. Surface cleaning treatment: ultrasonically clean the Ti6Al7Nb titanium alloy medical device to be treated with distilled water, dilute hydrochloric acid solution, acetone (analytical pure) and absolute ethanol (analytical pure) in sequence, and the time for each ultrasonic cleaning is 20 minutes , drying the Ti6Al7Nb titanium alloy medical device for medical use after ultrasonic cleaning at a temperature of 60°C; the mass concentration of the dilute hydrochloric acid solution is 2.5%;

[0065] 102. Alkali heat treatment: completely immerse the medical Ti6Al7Nb titanium alloy medical device dried in 101 in the NaOH solution with a concentration of 10mol / L, heat the NaOH solution to 80°C and keep it warm for 24h, and take out the medical Ti6Al7Nb titanium alloy medical device after cooling. Instruments were cleaned with deionized water;

[0066] Step 2, preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com