Method for preparing compound powder of alumina and chrome oxide from chromium-containing aluminum sludge

A composite powder, chromium oxide technology, applied in the direction of improving process efficiency, can solve problems such as pollution, and achieve the effects of no by-products, eradication of pollution problems, and control of product components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

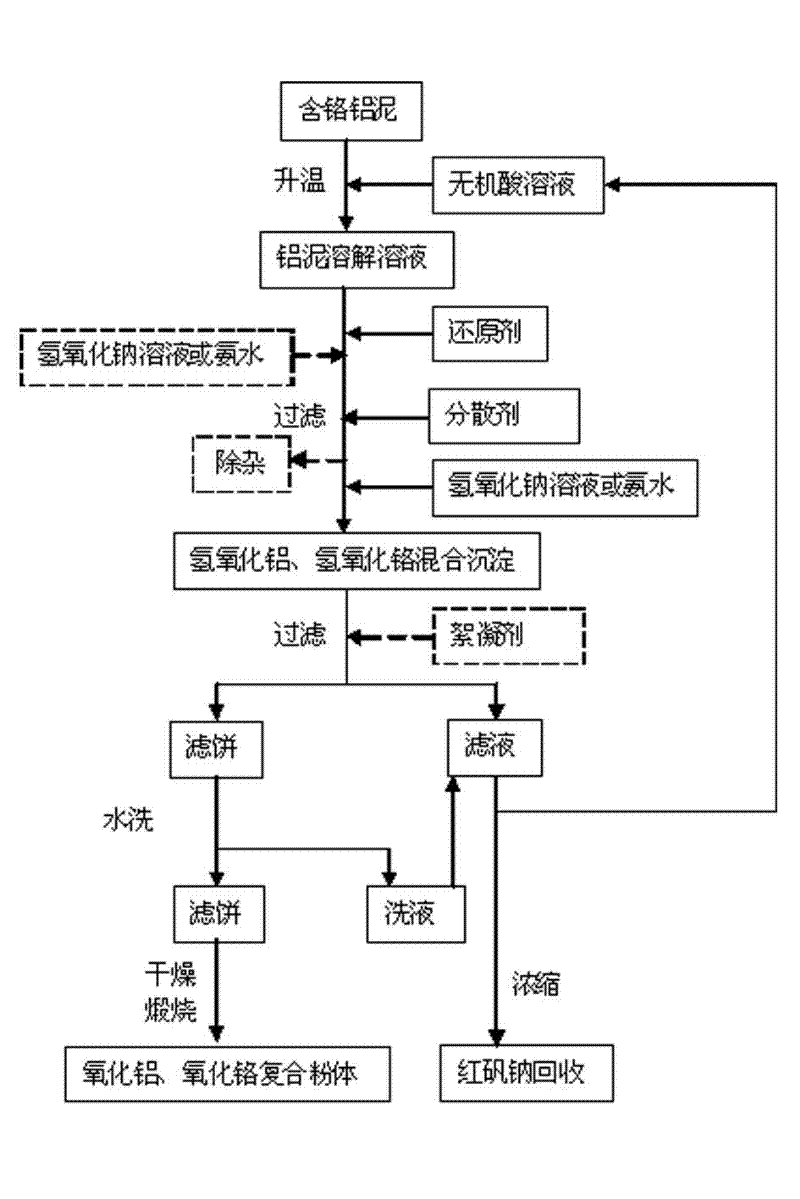

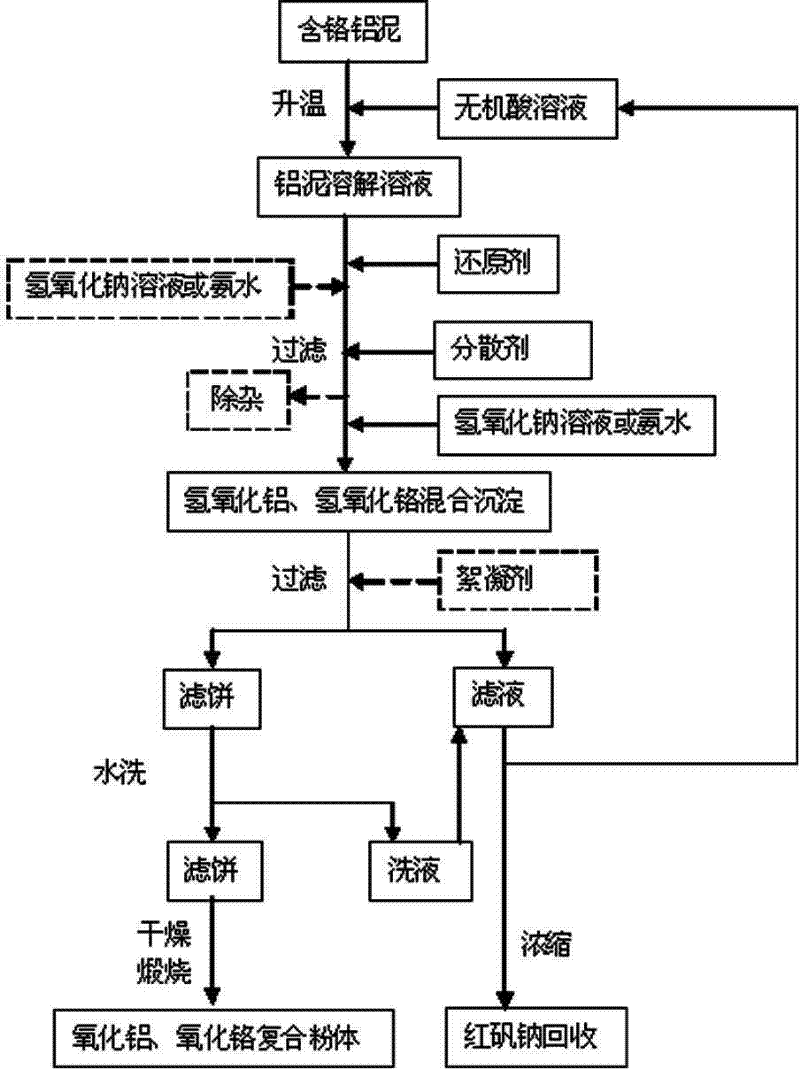

Method used

Image

Examples

Embodiment 1

[0028] Weigh 30 g of chromium-containing aluminum slime into a beaker, add 180 mL of 3 mol / L hydrochloric acid, raise the temperature to 80 °C under stirring conditions, continue stirring, and keep warm until the chromium-containing aluminum slime is completely dissolved to obtain an aluminum slime solution. Measure the concentration of Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) in the aluminum slime solution, and convert them to Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) 2 o 3 、Cr 2 o 3 、Al 2 o 3 According to the mass ratio of 1:1.5:100, add 1 g of glucose, stir, wait until the reaction is complete, let stand, and cool to room temperature. Add NaOH solution to pH 3.5, filter to remove Si and Fe impurities. Add 2.5 mL of polyethylene glycol 400, mix well, add NaOH solution until the pH is 7.7, and obtain Al(OH) 3 , Cr(OH) 3 Mix and precipitate, and obtain the filtrate and filter cake after filtration. Wash the filter cake with water until the washing liquid does not contain Cr(VI), and combine the washing li...

Embodiment 2

[0030] Weigh 50 g of chromium-containing aluminum slime into a beaker, add 50 mL of 6 mol / L sulfuric acid, raise the temperature to 100 °C under stirring conditions, continue stirring, and keep warm until the chromium-containing aluminum slime is completely dissolved to obtain an aluminum slime solution. Measure the concentration of Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) in the aluminum slime solution, and convert them to Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) 2 o 3 、Cr 2 o 3 、Al 2 o 3 According to the weight ratio of 2:1:100, 2 g of sucrose was added, stirred, and after the reaction was complete, it was left to stand and cooled to 50 °C. Add NaOH solution to pH 3.0, filter to remove Si and Fe impurities. Add 5 mL of absolute ethanol, mix well, then add NaOH solution until the pH is 7 to obtain Al(OH) 3 , Cr(OH) 3 Mix and precipitate, and obtain the filtrate and filter cake after filtration. Wash the filter cake with water until the washing liquid does not contain Cr(VI), and combine the washing liqu...

Embodiment 3

[0032] Weigh 30 g of chromium-containing aluminum slime into a beaker, add 150 mL of 5 mol / L nitric acid, raise the temperature to 30 °C under stirring conditions, continue stirring, and keep warm until the chromium-containing aluminum slime is completely dissolved to obtain an aluminum slime dissolution solution. Measure the concentration of Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) in the aluminum slime solution, and convert them to Cr(Ⅲ), Cr(Ⅵ) and Al(Ⅲ) 2 o 3 、Cr 2 o 3 、Al 2 o 3 According to the mass ratio of 2:3:100, 1 mL of formaldehyde was added, stirred, and after the reaction was complete, it was left to stand and cooled to room temperature. Add NaOH solution to pH 2.5, filter to remove Si and Fe impurities. Add solution quality 5g sodium dodecylsulfonate, after mixing evenly, add NaOH solution until pH is 6.8, get Al(OH) 3 , Cr(OH) 3 mixed sediment. Add 0.3 mL of 5‰ polyacrylamide flocculant, and filter after the precipitation is complete to obtain the filtrate and filter cake....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com