Card base film

A film and card base technology, applied in the field of card base film, can solve the problems of low temperature resistance, poor environmental protection of polyvinyl chloride, easy warping of copolyester, etc., achieve good safety protection function, improve production environment, and simplify processing The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

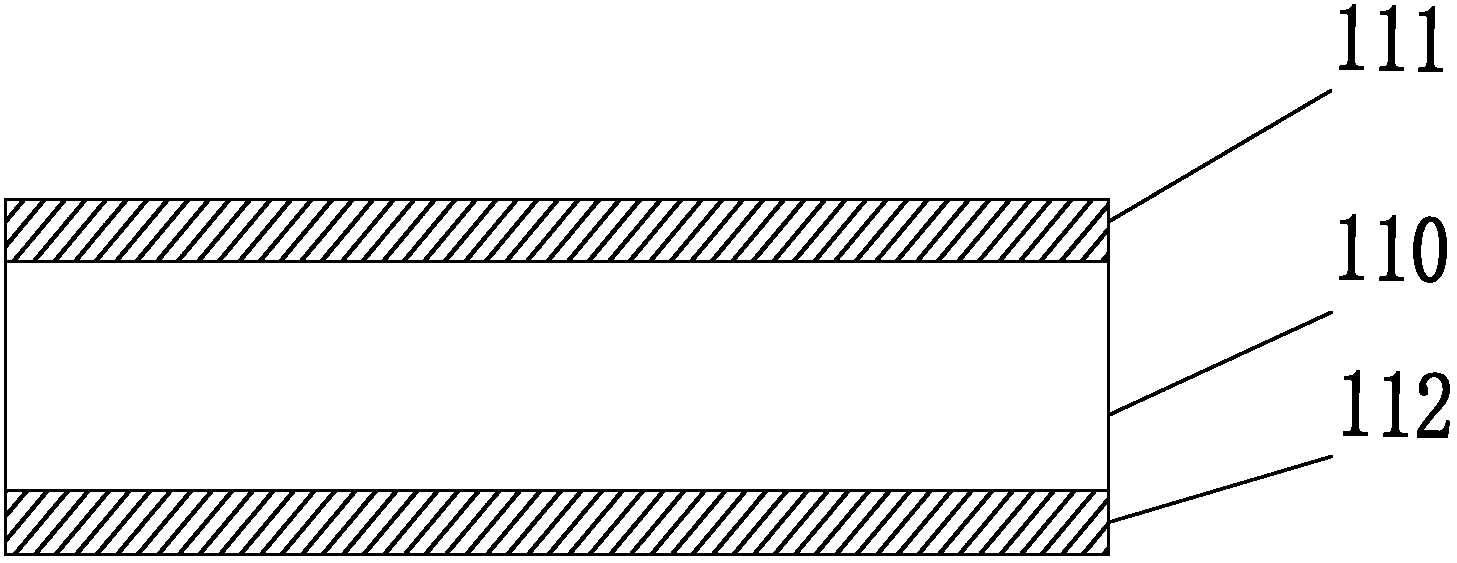

[0024] Such as figure 1 As shown, the card base film in this embodiment includes a polymer material body 110, a first surface texture structure layer 111 and a second surface texture structure layer 112, and the polymer material body 110 is arranged on the first surface texture structure layer 111 Between the second surface texture structure layer 112, the first surface texture structure layer 111 and the second surface texture structure layer 112 are both sand surfaces, which can resist scratches, wear resistance, further enhance surface printability and Thermal compound formability effect.

[0025] The composition of the card-based film includes engineering plastics, white powder, antioxidant, anti-ultraviolet absorber, impact modifier, flame retardant, antistatic agent, dispersant, and colorant.

[0026] The engineering plastics are composed of polycarbonate, polyethylene terephthalate, polystyrene, polyamide, polyethylene terephthalate-1,4-cyclohexanedimethanol ester.

...

Embodiment 2

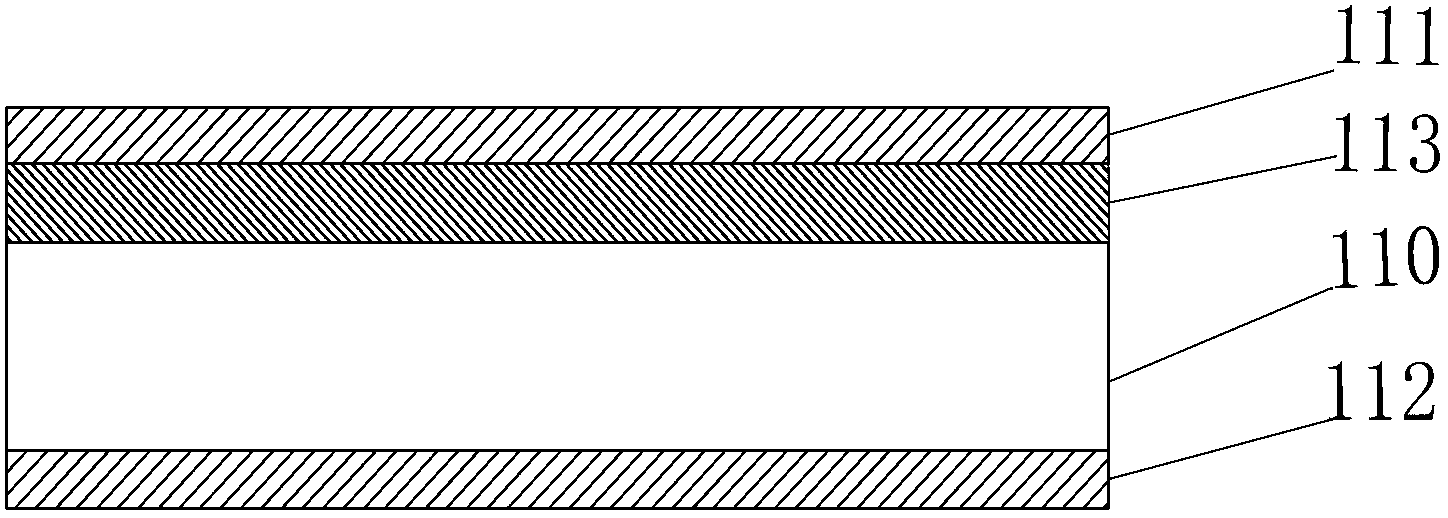

[0037] Such as figure 2 As shown, the card base film in this embodiment includes a polymer material body 110, a first surface texture structure layer 111 and a second surface texture structure layer 112, and the polymer material body 110 is arranged on the first surface texture structure layer 111 and the second surface texture structure layer 112, the first composite film layer 113 is arranged between the polymer material body 110 and the first surface texture structure layer 111, the first surface texture structure layer and the The second surface texture structure layer is a sand surface.

[0038] The feature of this embodiment is that the first composite film layer 113 can significantly enhance the adhesion with different engineering plastics, thereby further broadening its application range and meeting different application requirements.

[0039] The composition of the card-based film includes engineering plastics, white powder, antioxidant, anti-ultraviolet absorber, i...

Embodiment 3

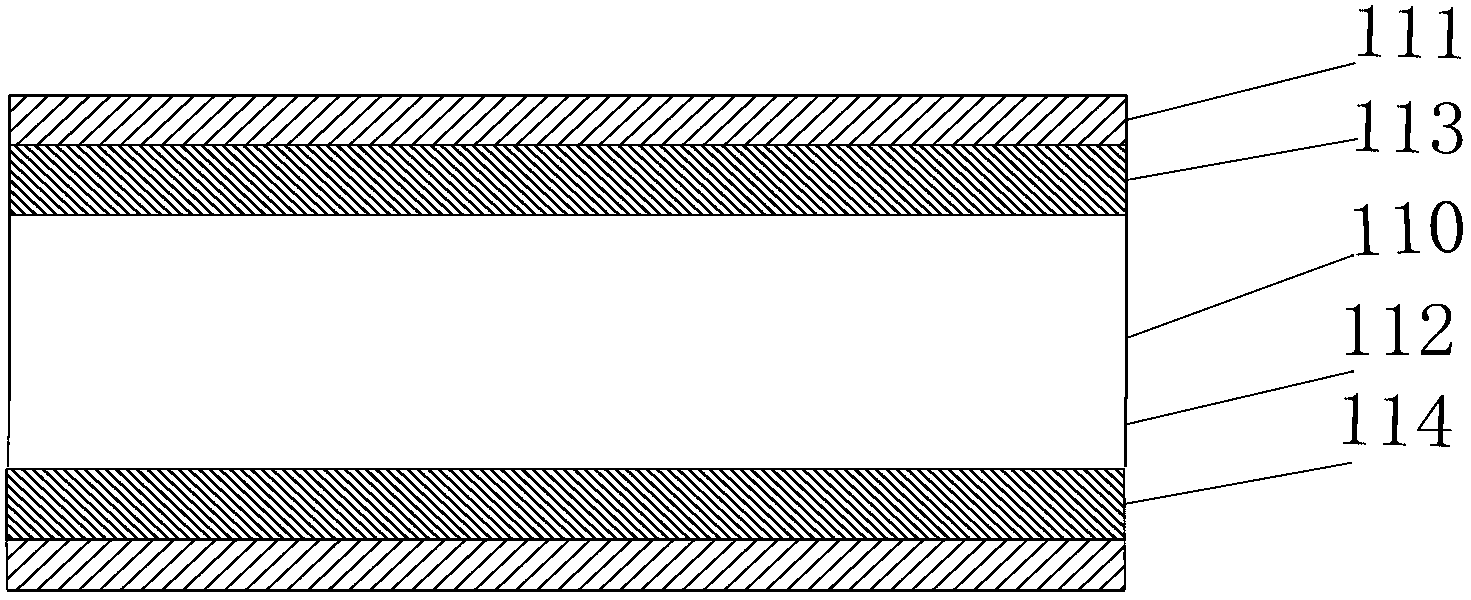

[0044] Such as image 3 As shown, the card base film in this embodiment includes a polymer material body 110, a first surface texture structure layer 111 and a second surface texture structure layer 112, and the polymer material body 110 is arranged on the first surface texture structure layer 111 and the second surface texture structure layer 112, the first composite film layer 113 is arranged between the polymer material body 110 and the first surface texture structure layer 111, and the second composite film layer (114) is arranged on the Between the polymer material body (110) and the second surface texture structure layer (112), the first surface texture structure layer and the second surface texture structure layer are sand surfaces.

[0045] The composition of the card-based film includes engineering plastics, white powder, antioxidant, anti-ultraviolet absorber, impact modifier and flame retardant.

[0046] The engineering plastics are composed of polycarbonate, polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com