Closed-loop control system for treating landfill leachate in cooperation with partial nitrosation and denitrification and denitrifying and decarburizing method thereof

A technology of landfill leachate and closed-loop control, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of process economy and sustainability not reaching a higher level, unfavorable advanced treatment of organic matter, inconvenient operation, etc. , to achieve stable water discharge effect, stable operation, and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

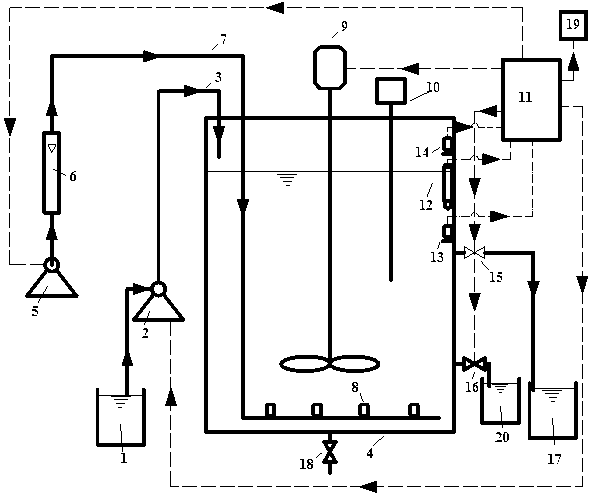

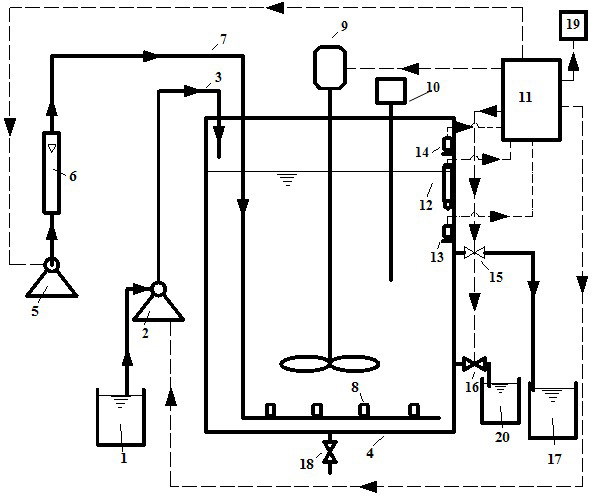

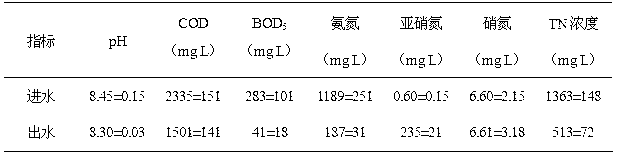

[0029] like figure 1 As shown, the closed-loop control system of partial nitrification combined with denitrification to treat landfill leachate includes automatic control, constant temperature, alarm, stirring, aeration, water inlet, water outlet, and sludge discharge systems. The solid line with the arrow in the figure is the physical pipeline connection, and the dotted line is the signal control connection connected with the programmable controller 11 . The automatic control system is mainly composed of a programmable controller 11, which is connected with other systems, so as to achieve automatic control of each operation link of the reactor. Specifically: the programmable controller 11 is connected with the water inlet pump 2, the water outlet solenoid valve 15, the mud discharge solenoid valve 16, the mixer 9, the blower 5, the pH sensor 12, the water outlet float switch 13, the alarm float switch 14 and the alarm 19 It is connected to automatically control the operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com