Method for preparing glycerin shrinkage benzaldehyde

A technology of benzaldehyde and glycerin, applied in the direction of organic chemistry, can solve the problems of strong corrosion of equipment, low active point density, long reaction time, etc., and achieve the effect of low corrosion of equipment, high conversion rate of glycerin and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

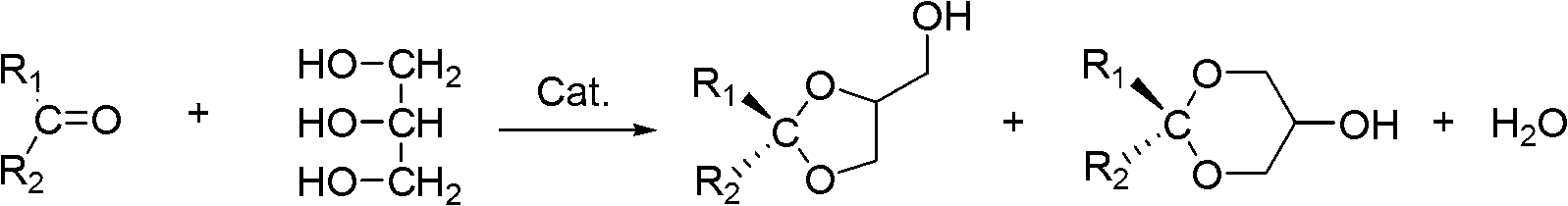

Image

Examples

Embodiment 1

[0032] Add 2.33g (10mmol) bisulfate N-butylpyridine ([BPy]HSO) successively in reactor 4 ) ionic liquid and 27.6g (0.3mol) glycerol, stir and mix; then add 10.6g (0.1mol) benzaldehyde to the reaction kettle in sequence, heat slowly under stirring, and raise the temperature to 70°C to make the nucleophilic addition reaction proceed 120 minutes; Wherein, the mol ratio of glycerol and benzaldehyde is 3:1. After the reaction is over, the reaction kettle is left to stand, and the system is automatically divided into upper and lower layers. The upper layer is a mixture phase of reactants and products, and the lower layer is an ionic liquid and unreacted glycerin phase. Directly separate the upper oil phase for qualitative and quantitative NMR detection, and use CH for the lower layer 2 Cl 2Glycerin and ionic liquid are extracted and separated, and the ionic liquid can be recovered and reused by removing the organic solvent under reduced pressure. The oil phase was quantified wit...

Embodiment 2

[0034] In reactor, add 6.32g (20mmol) bisulfate radical 1-methyl-3-butylsulfonic acid base imidazoles ([BSMim]HSO) successively 4 ) ionic liquid and 13.8g (0.15mol) glycerol, stir and mix; then add 10.6g (0.1mol) benzaldehyde to the reaction kettle in turn, heat slowly under stirring, and raise the temperature to 25°C to allow the nucleophilic addition reaction to proceed 180 minutes; Wherein, the mol ratio of glycerol and benzaldehyde is 1.5:1. After the reaction is over, the reaction kettle is left to stand, and the system is automatically divided into upper and lower layers. The upper layer is a mixture phase of reactants and products, and the lower layer is an ionic liquid and unreacted glycerin phase. Directly separate the upper oil phase, conduct qualitative and quantitative NMR detection, and use CH 2 Cl 2 Glycerin and ionic liquid are extracted and separated, and the ionic liquid can be recovered and reused by removing the organic solvent under reduced pressure. Th...

Embodiment 3

[0036] Add 1.84g (5mmol) trifluoromethanesulfonate radical 1-methyl-3-butylsulfonate imidazole ([BSMim]CF) successively in the reactor 3 SO 3 ) ionic liquid and 46.045g (0.5mol) glycerol, stir and mix; then add 10.6g (0.1mol) benzaldehyde to the reaction kettle in turn, heat slowly under stirring, and raise the temperature to 50°C to make the nucleophilic addition reaction proceed 5 minutes; Wherein, the mol ratio of glycerol and benzaldehyde is 5:1. After the reaction is over, the reaction kettle is left to stand, and the system is automatically divided into upper and lower layers. The upper layer is a mixture phase of reactants and products, and the lower layer is an ionic liquid and unreacted glycerin phase. Directly separate the upper oil phase, conduct qualitative and quantitative NMR detection, and use CH 2 Cl 2 Glycerin and ionic liquid are extracted and separated, and the ionic liquid can be recovered and reused by removing the organic solvent under reduced pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com